Prefabricated formwork-free floor slab and construction method

A construction method and formwork-free technology, which is applied in the processing of floor slabs, building materials, construction, etc., can solve the problems of high production labor cost, long time-consuming formwork, large workload, etc., and achieve convenient and fast construction, short construction period, and engineering low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

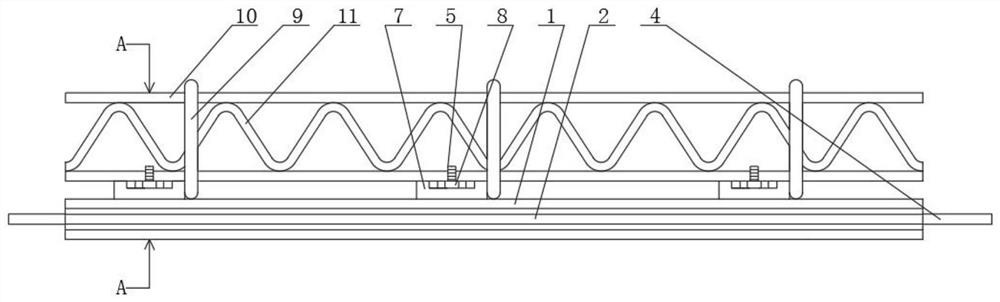

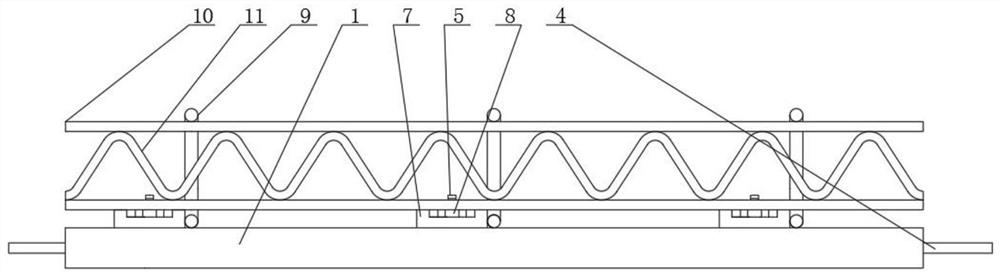

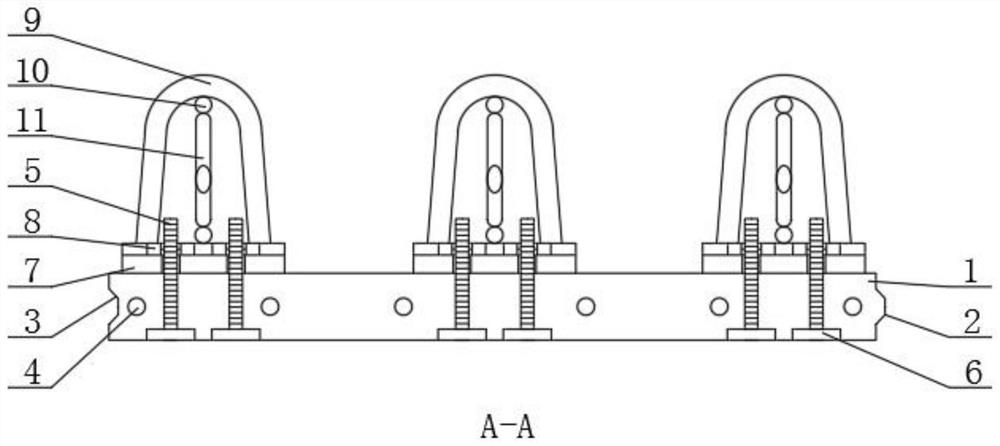

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0040] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , a prefabricated formwork-free floor slab, comprising a plank 1, the plank 1 is a reinforced cement fiber board with a thickness of 12mm, which is prefabricated in a factory as a whole, the right side of the plank 1 is provided with a side strip 2, and the plank 1 and the side strip 2 are integrated The front and rear lengths of the side bar 2 are the same as those of the plank 1. The cross section of the side bar 2 is isosceles trapezoidal. Inserted into the slot 3, when the edge strip 2 is slid into the slot 3, after the adjacent planks 1 are docked, there will be no upper and lower standard deviation at the butt joint, and the sealing performance is effectively improved, and the plank 1 is un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com