Automatic reset type pressing opening and closing device

A technology of automatic reset and opening and closing device, applied in the direction of leaf leaf opener, leaf leaf closer, door/window accessories, etc. problems, to achieve the effect of facilitating integrated settings, facilitating daily use and maintenance, and improving connection compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

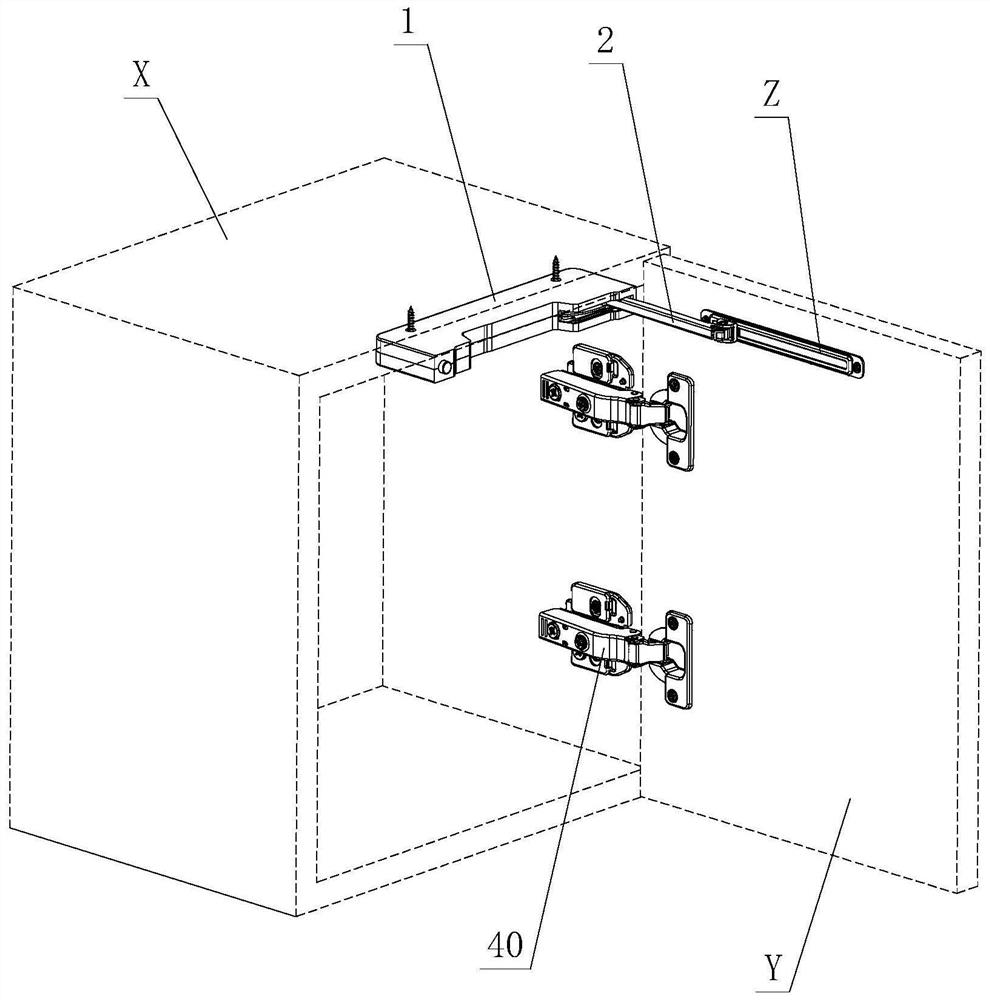

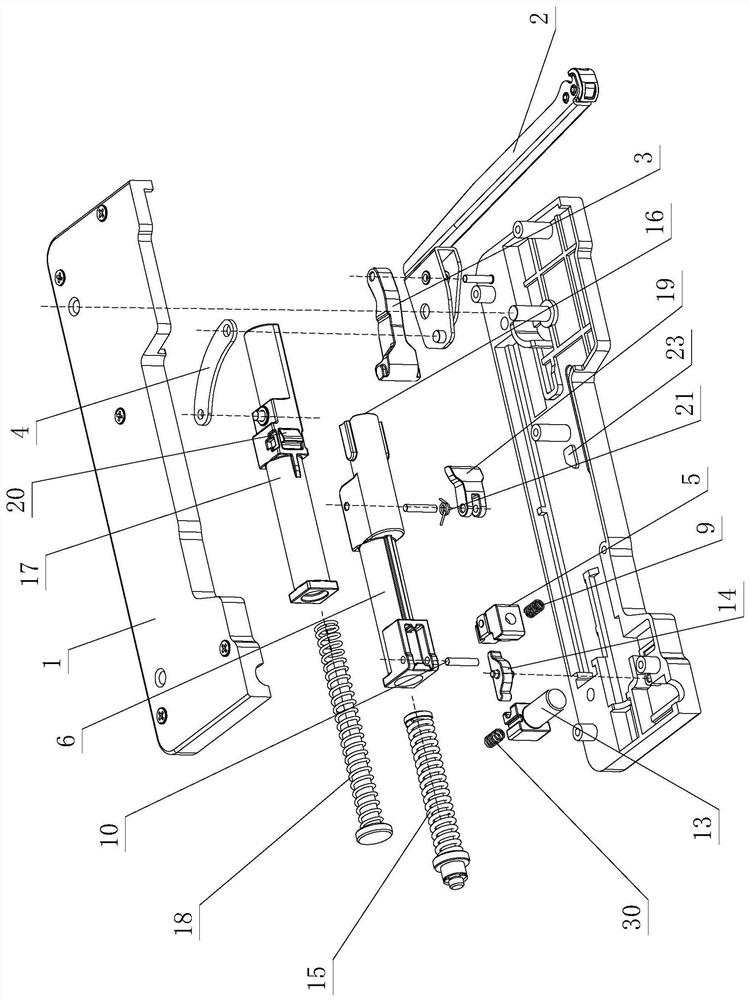

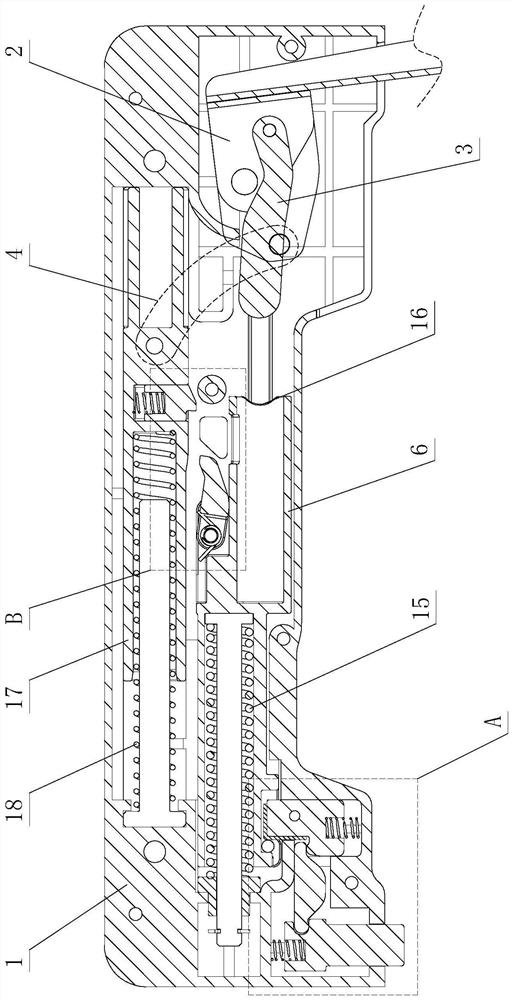

[0052] see Figure 1-Figure 11 , The self-resetting press opening and closing device includes a bracket 1, a connecting arm 2 is arranged on the support 1, and a pressing assembly, a pushing assembly, and an opening and closing assembly that are independently elastically movable.

[0053] The connecting arm 2 is hinged to open and close on the bracket 1, and the push transmission part 3 and the opening and closing transmission part 4 are respectively hinged on it, and are mutually driven by the push transmission part 3, the opening and closing transmission part 4, the push assembly and the opening and closing assembly respectively. connect.

[0054] A reset assembly is arranged between the push assembly and the opening and closing assembly, and the two are reset and matched by the reset assembly when the connecting arm 2 is hinged and opened.

[0055] An arc fitting portion is provided between the pressing assembly and the pushing assembly, and the two are locked or unlocked ...

no. 2 example

[0092] see Figure 12-Figure 16 , the automatic reset push switch device is different from the first embodiment in that: a reset component is provided between the push component and the switch component, and the two are reset and matched by the reset component when the connecting arm 2 is hinged and closed.

[0093] The pressing part 13 presses and moves when the connecting arm 2 is in the closed state, and drives the lock-off part 5 to overcome the elastic force of the lock-off elastic part 9 to slide on the bracket 1 through the intermediate piece 14, and the lock-off part 11 passes through when the lock-off part 5 slides. The arc-shaped lock release position 7 and the arc-shaped active position 8 are mutually unlocked in the form of an arc, so as to realize the automatic complete hinged opening of the connecting arm 2 relative to the bracket 1 to the terminal position.

[0094] The pushing member 6 slides elastically and linearly on the bracket 1 through the pushing elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com