Structure for generating sliding arc and plasma igniter with structure

A plasma and sliding arc technology, applied in the direction of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve the problems of insufficient arc energy and unadjustable, so as to improve the success rate of ignition, avoid energy waste, and ensure The effect of full exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

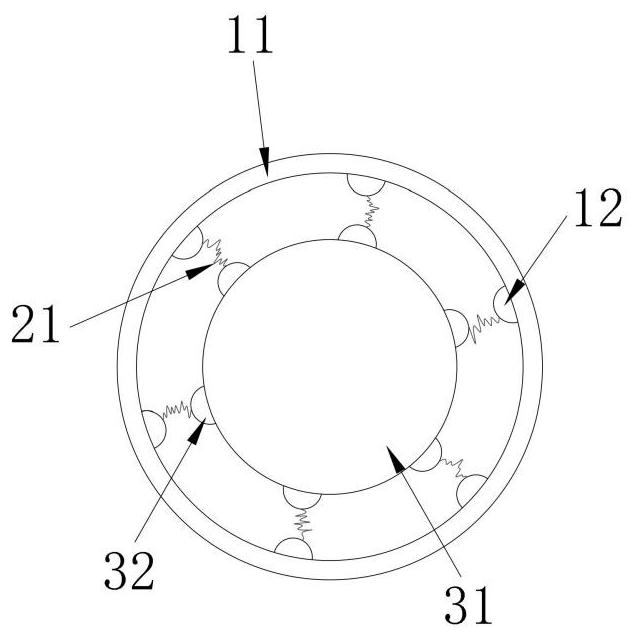

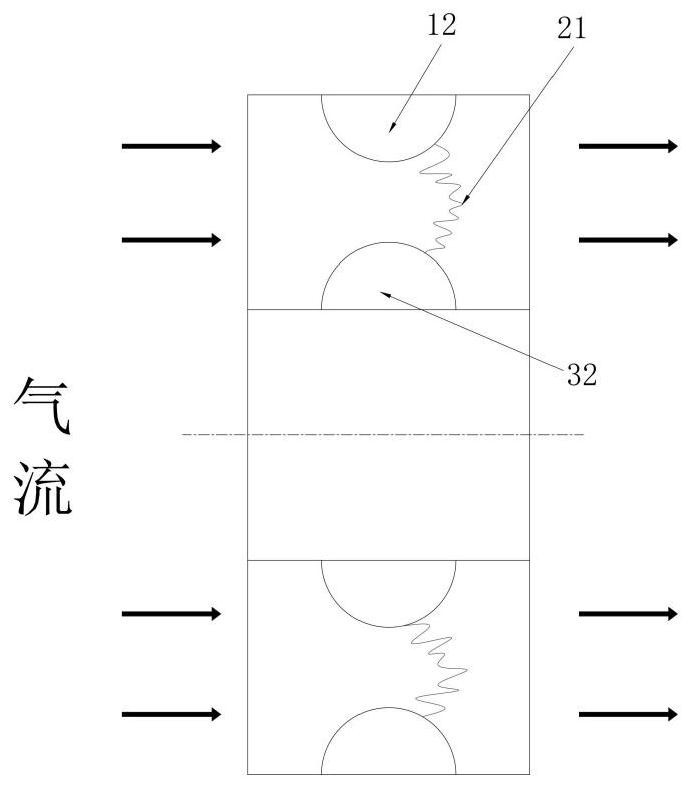

[0029] like Figure 1-2 As shown, a structure for generating a sliding arc includes a high voltage electrode seat 11 , a high voltage electrode 12 , a ground electrode seat 31 and a ground electrode 32 . Wherein, the high voltage electrode 12 and the ground electrode 32 are arranged in a ring around the ground electrode seat 31 . During operation, the high-voltage electrode 12 or the ground electrode 32 rotates around the central axis ground electrode seat 31, and at the same time, the airflow flows through the sliding arc generation area between the high-voltage electrode and the ground electrode. After a sufficient voltage is applied to the high-voltage electrode, an arc will be generated between the high-voltage electrode 12 and the ground electrode 32. Due to the existence of airflow, the arc will slide along the direction of movement of the airflow when crossing the surface of the high-voltage electrode and the surface of the low-voltage electrode. A sliding arc 21 is ge...

Embodiment 2

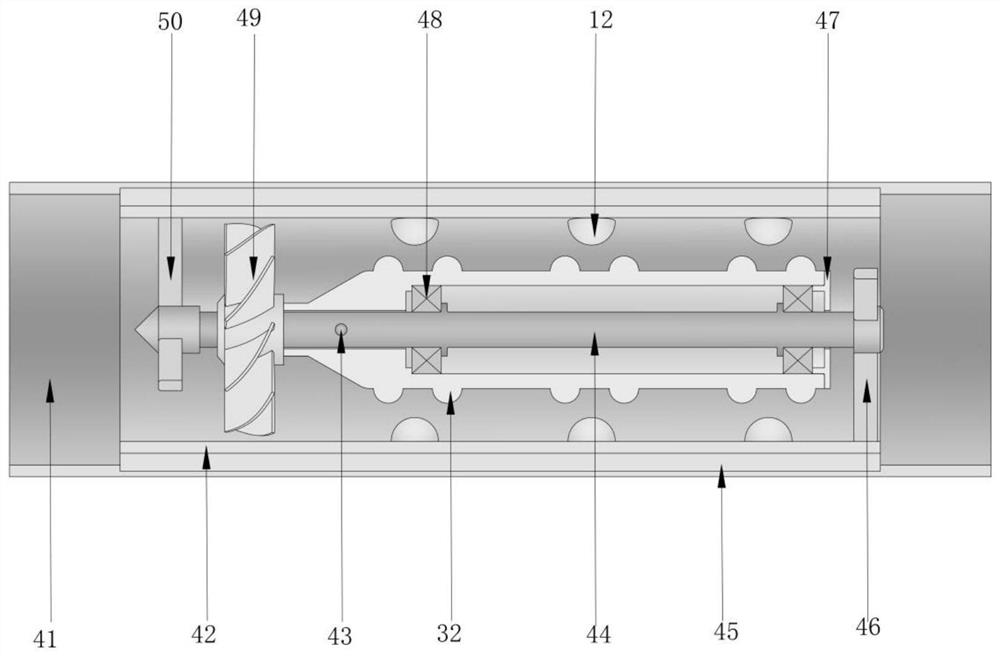

[0032] like Figure 3-7 As shown, a plasma igniter with a rotating sliding arc includes an igniter casing, one end of the igniter casing is the front incoming flow area, and the other end is the rear ignition area, and the front incoming flow area and the A structure for generating a sliding arc is provided between the fire areas at the tail, and the structure includes a grounding electrode seat installed on the central shaft, and a turbine connected to the grounding electrode seat is sleeved on the air intake end of the central shaft. The central axis of the high voltage electrode 12 is the same as that of the ground electrode 32 , and the high voltage electrode 12 is distributed in a circular array along the circumferential direction on the high voltage electrode insulating seat 42 . Each high-voltage electrode 12 is independently powered by a plasma power supply, and the high-voltage electrodes 12 are distributed in a linear array along the axial direction to ensure effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com