Efficient and energy-saving screw type air compressor

A high-efficiency, energy-saving, screw-type technology, applied in the direction of rotary piston machinery, mechanical equipment, machines/engines, etc., can solve the problems of insufficient stability and poor heat dissipation effect, and achieve rapid and efficient cooling and heat dissipation, stable placement, and comprehensive heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0027] The embodiments of the present invention will be described below according to the overall structure of the present invention.

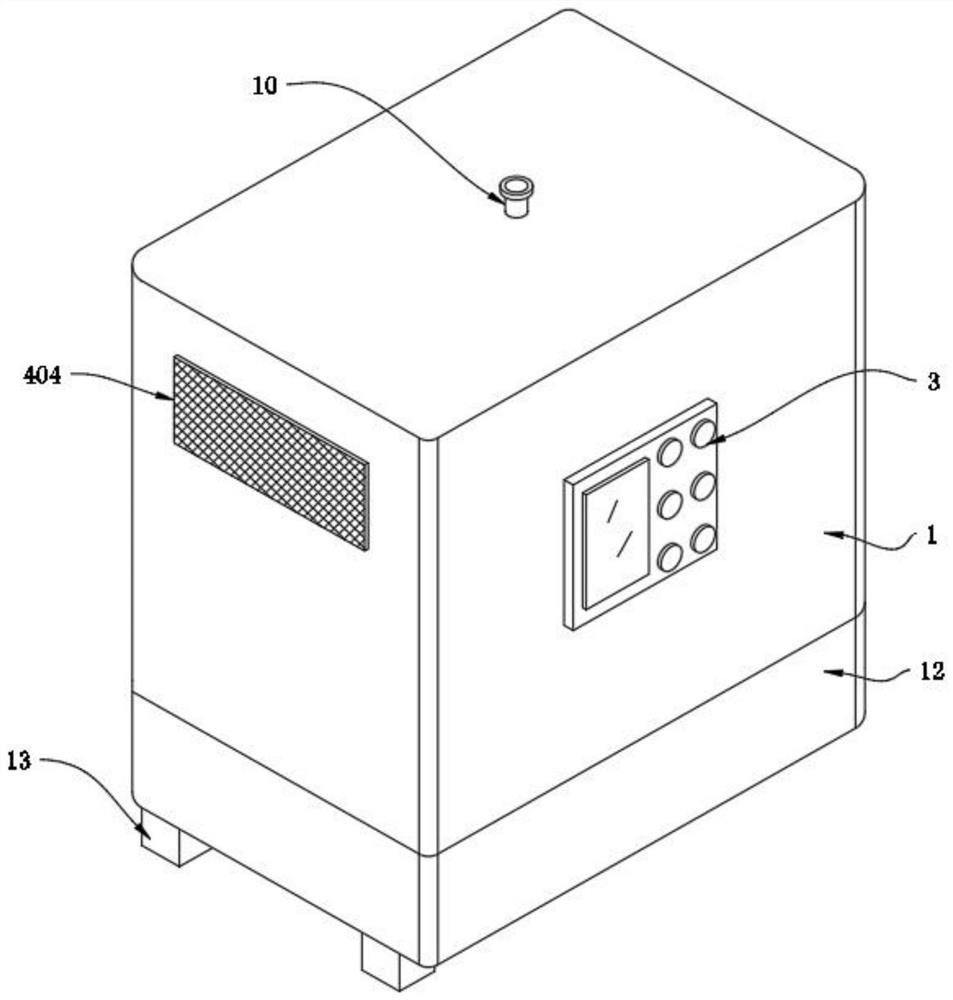

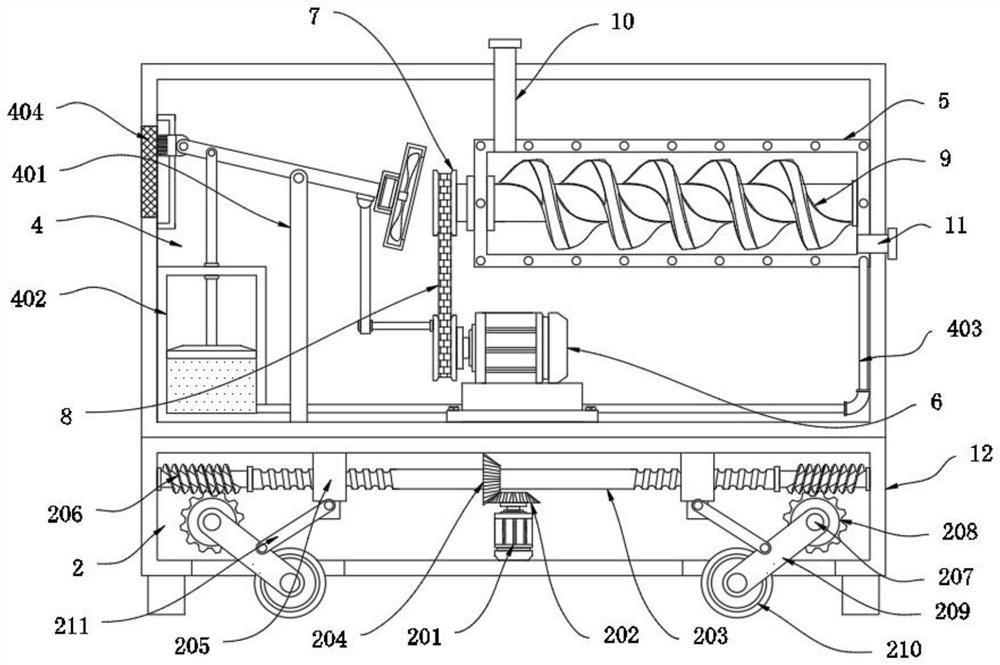

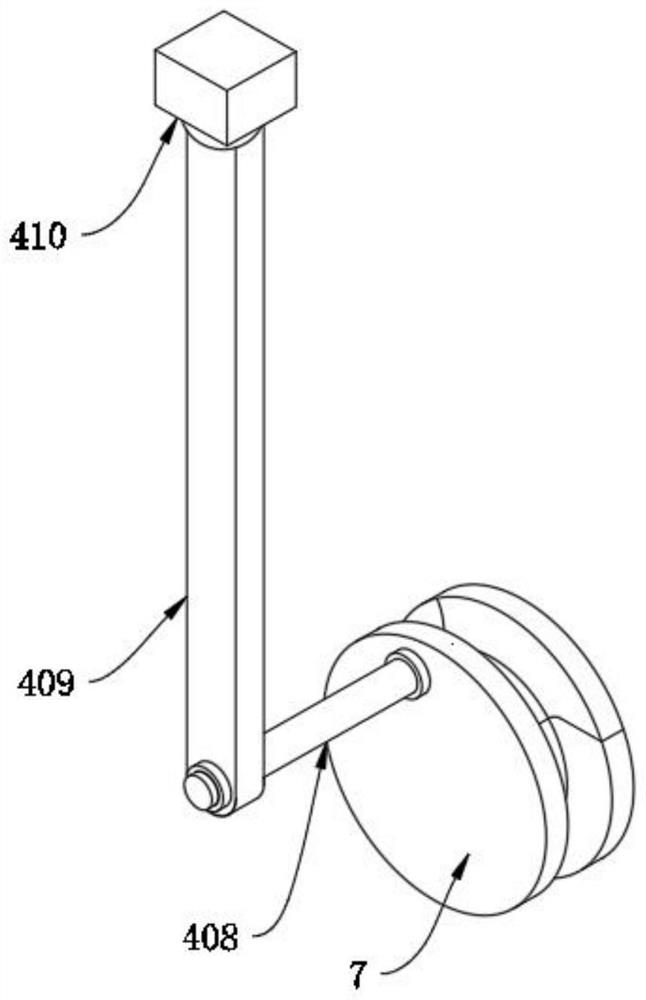

[0028] A high-efficiency and energy-saving screw air compressor, such as Figure 1-4 Shown, comprise cabinet body 1, casing 5, base 12 and driving motor 6, casing 5 and driving motor 6 are all positioned at the inside of cabinet body 1, screw rod 9 is installed in the inside of casing 5, casing 5 top and One side runs through the air inlet pipe 10 and the air outlet pipe 11 respectively, and one end of the screw rod 9 and the output end of the drive motor 6 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com