A high-speed and high-precision three-dimensional detection system and method

A three-dimensional detection, high-precision technology, applied in the field of three-dimensional measurement, can solve the problems of reducing the detection speed of equipment, increasing the time of mechanical movement and image acquisition, and achieving the effect of expanding the detection range of height and meeting the needs of diversified detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

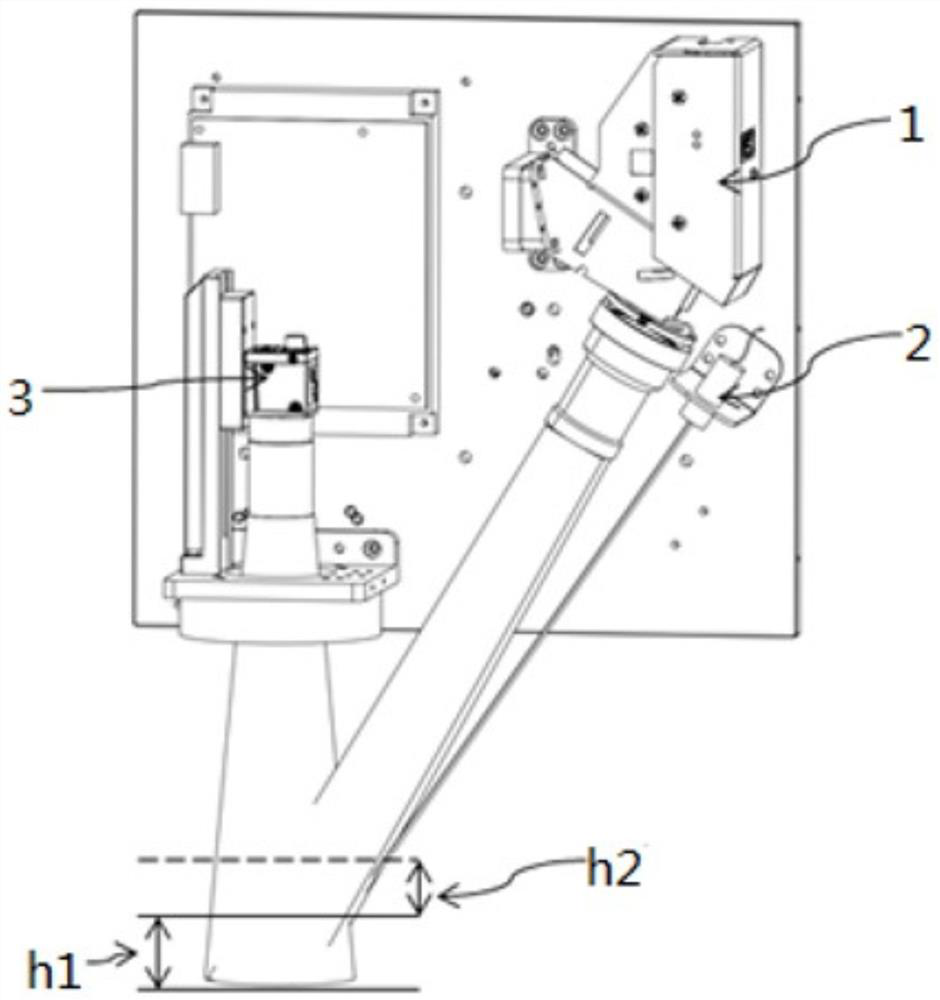

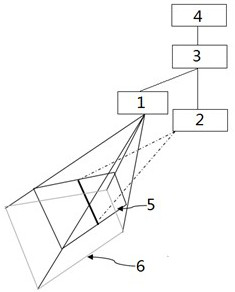

[0049] like figure 1 , figure 2 As shown, the present invention provides a high-speed and high-precision three-dimensional detection system, comprising: a detection device, the detection device includes at least a first projection device 1, at least a second projection device 2, and an image acquisition device 3; A projection device 1 is used to project at least one structured light to the object to be measured, the second projection device 2 is used to project at least one type of linear light source to the object to be measured, and the image acquisition device 3 is used to capture the first Structured light projection images and line light source projection images projected by the projection device 1 and the second projection device 2 on the object to be measured; the processor 4 is used to obtain the structured light projection images and the line light source projection images, according to the structured light projection images. Calculate the three-dimensional height d...

Embodiment 2

[0059] A high-speed and high-precision three-dimensional detection system. The high-speed and high-precision three-dimensional detection system provided by this embodiment is basically the same as that of the first embodiment. The main difference lies in the number of the first projection device 1 and the second projection device 2 described in this embodiment. Both are two, that is, this embodiment is a dual projection mode.

Embodiment 3

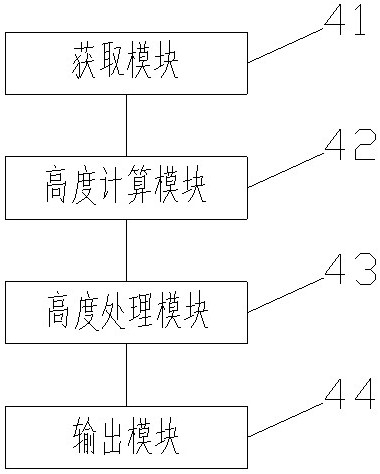

[0061] like Image 6 As shown, this embodiment provides a high-speed and high-precision three-dimensional detection method, which is applied to the high-speed and high-precision three-dimensional detection systems described in Embodiments 1 and 2, and includes the following steps:

[0062] S1. Set the initial position, turn on the image acquisition device 3 and the second projection device 2, so that the detection device and the object to be measured move relatively. During the movement of the image acquisition device 3, the second projection device 2 is used to project at least a line light source

[0063] S2, using the image acquisition device 3 to acquire the projection image of the line light source projected by the second projection device 2 on the object to be measured;

[0064] S3. When the image acquisition device 3 reaches the first position, turn off the second projection device 2, turn on the first projection device 1, and project at least one structured light to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com