Design method for rubber free molded surface of node type product

A design method, rubber-type technology, applied in design optimization/simulation, special data processing applications, complex mathematical operations, etc., can solve problems such as individual design, achieve high life requirements, and improve design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

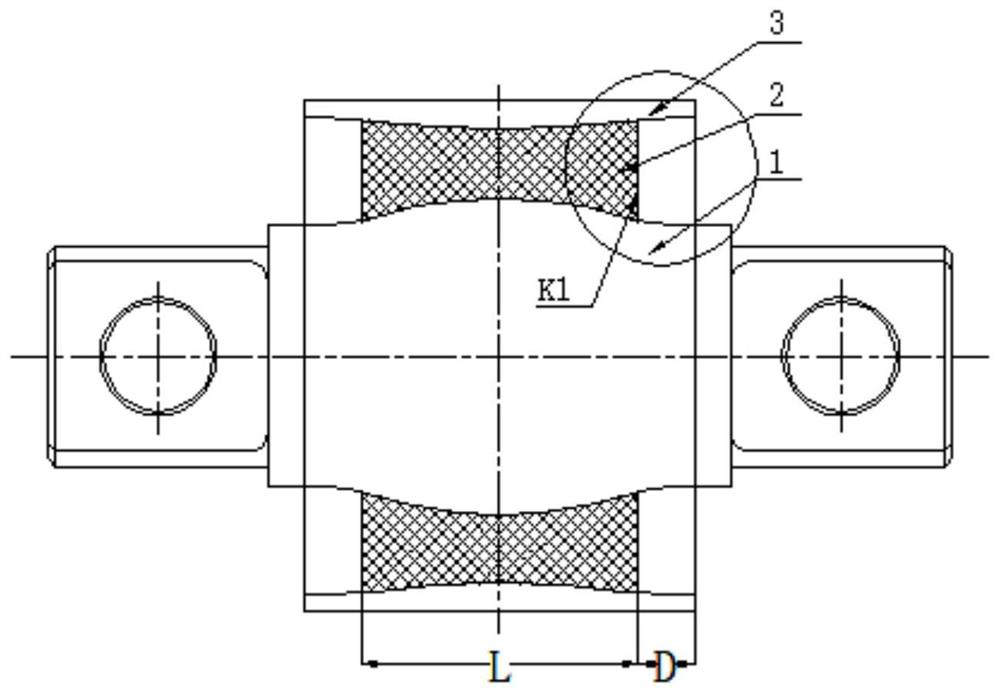

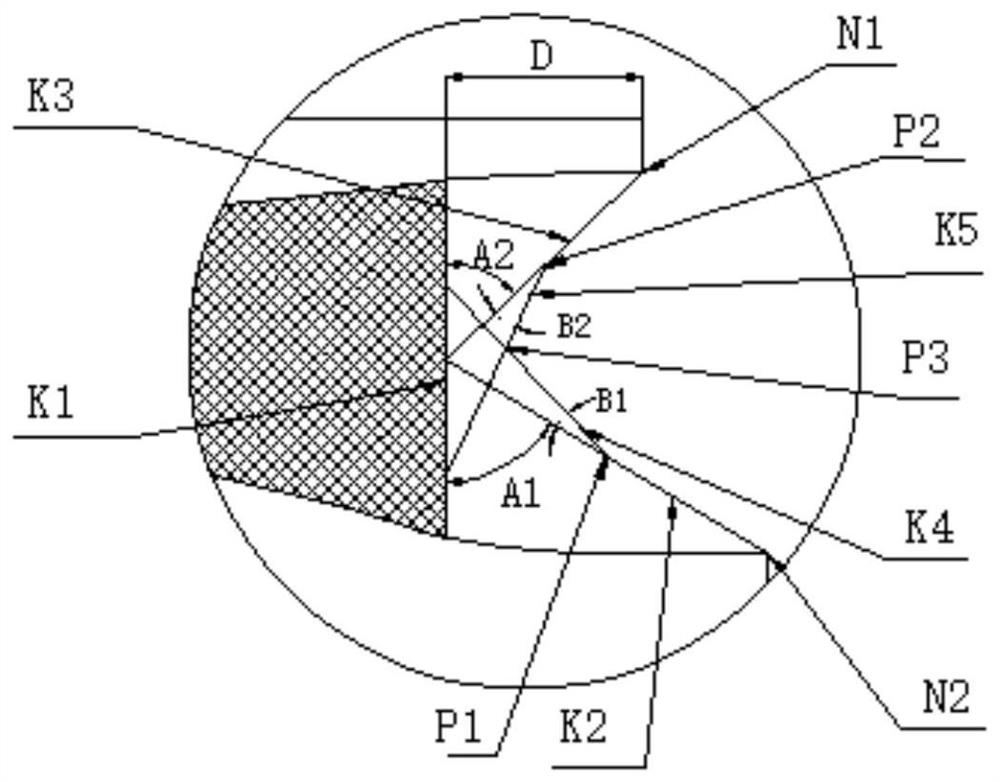

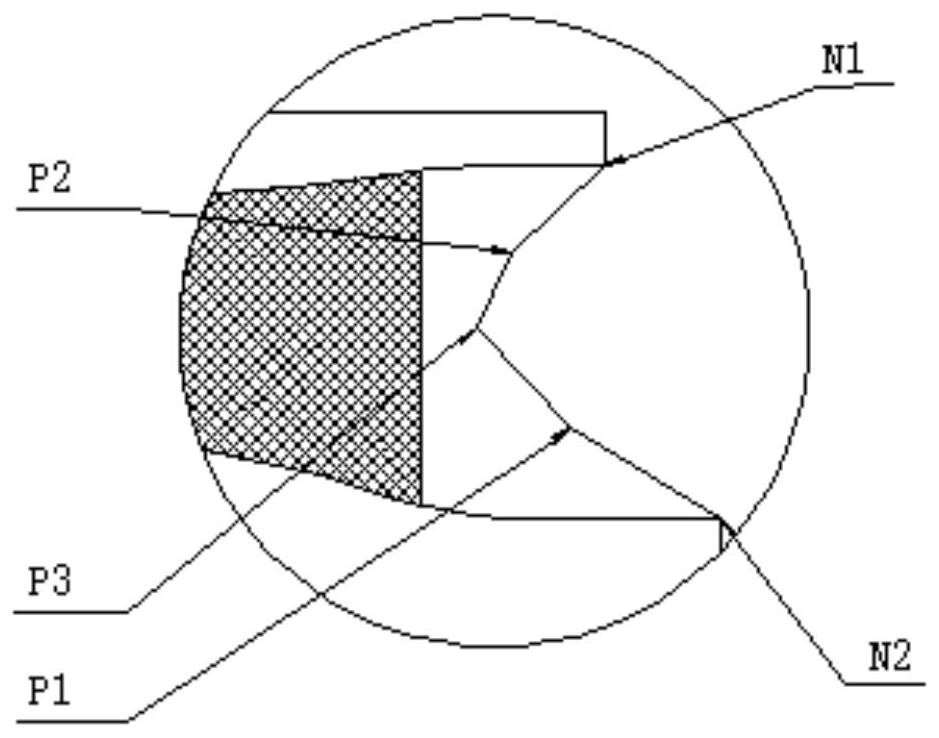

[0033] like Figure 1-Figure 5 As shown in Fig. 1, a rubber free-form surface design method for joint products, because different joint products are used in different environments, have different performance requirements and installation conditions, therefore, firstly, according to the interface size and stiffness performance requirements of the product The effective load-bearing length L of the rubber body 2 in the product is analytically calculated through the following equations of the isotropic stiffness of the rubber nodes:

[0034]

[0035]

[0036]

[0037]

[0038] Among them: L is the length of rubber body 2, G is the shear modulus of rubber, R2 is the outer diameter of rubber body 2, R1 is the inner diameter of rubber body 2, M is the correlation coefficient of rubber hardness, and S is the bearing area ratio of inner and outer diameters ,δ 1 ,δ 2 ,δ 3 ,δ 4 Calculates the correction factor for the stiffness. In the above equations, there are only thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com