Cat food for conditioning intestines and stomach and improving digestion and absorption and preparation method thereof

A digestion and absorption, gastrointestinal technology, applied in animal feed, additional food elements, animal feed, etc., can solve the problems of affecting animal regulation, insufficient nutritional value, unstable meat source, etc., to inhibit the reproduction of harmful bacteria and enhance immunity , the effect of protecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

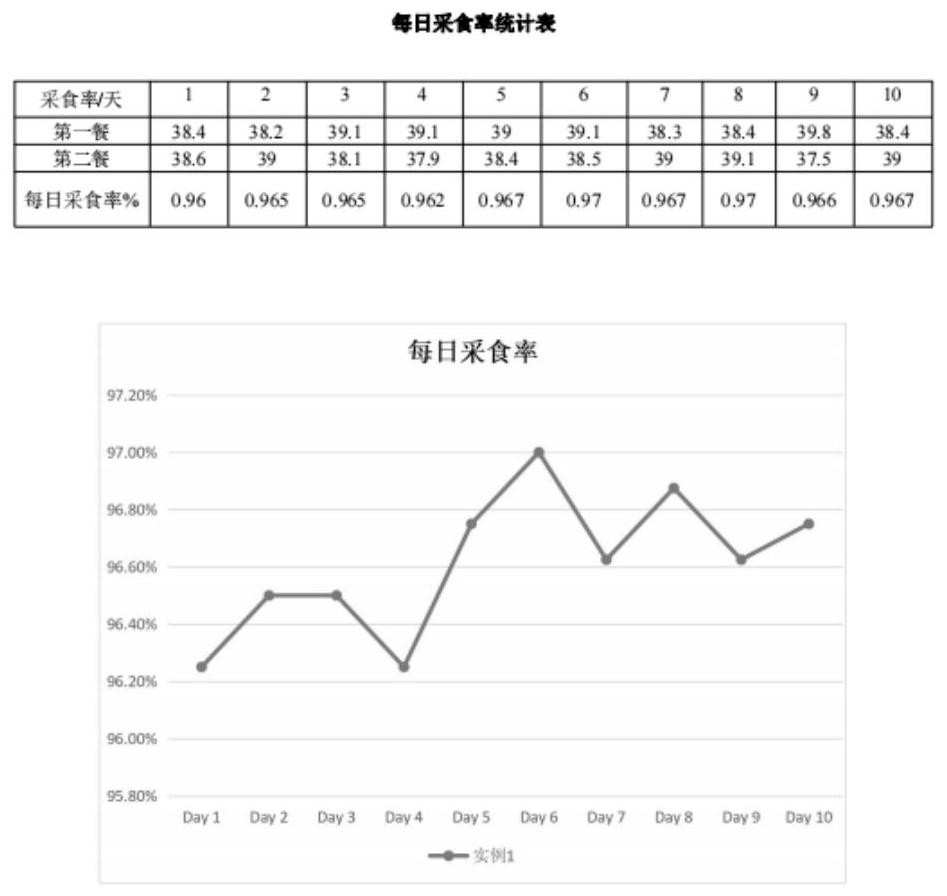

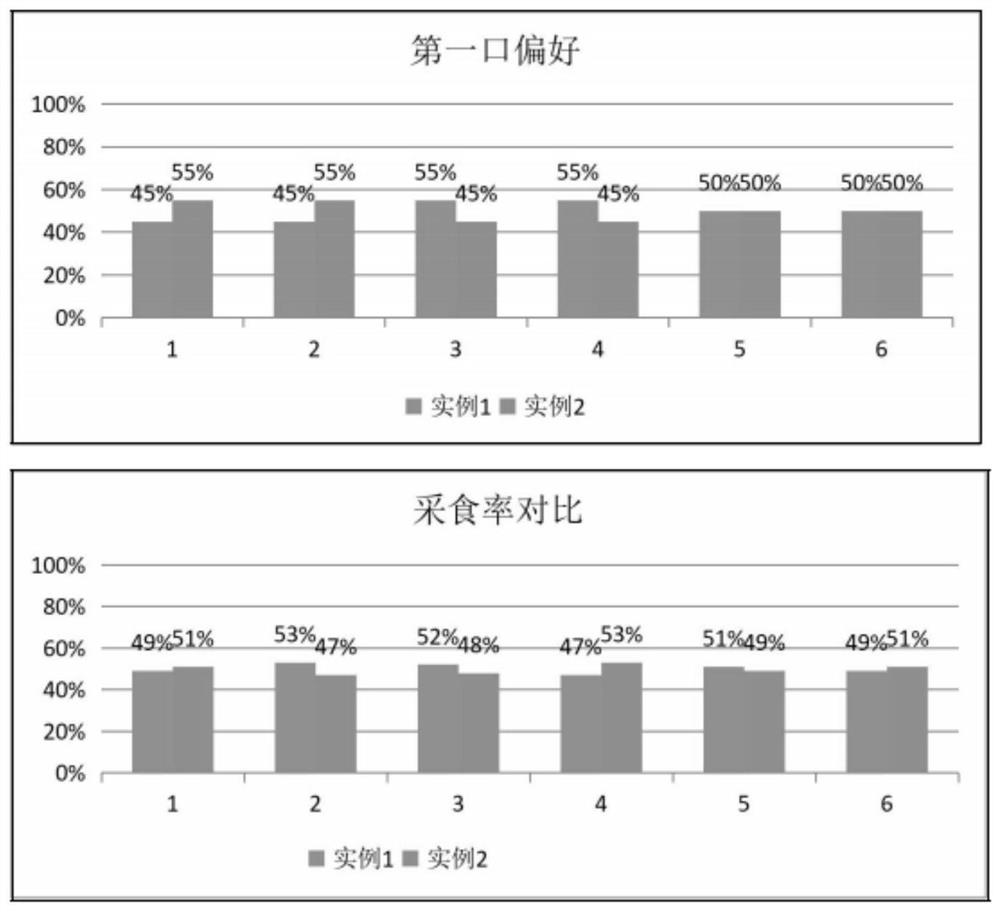

Embodiment 1

[0032] Example 1, see Figure 1-Figure 2 ,

[0033] S1: Raw material treatment: use qualified meat raw materials, and the meat used has been treated with enzymatic hydrolysis to generate small molecular polypeptides.

[0034]S2: Granule preparation: crush and pre-mix the dry raw materials, add meat, vegetables and water, and then puff them into shapes. The puffing mold is used to make a circular shape with holes. After drying, it is mixed evenly with oil, enzymatically hydrolyzed chicken liver, and chicken liver powder. After cooling, add minced chicken breast and mix evenly. The mass percentage of raw materials added is as follows: 30% chicken, 15% squab, 14% chicken powder, 10% potato, 8% oil, 7% fish meal, 6% fruit and vegetable, and 3% egg %, beer yeast powder 1.65%, alfalfa granules 2%, vitamins and minerals 1.1%, postbiotic microcapsules 0.4%, spirulina powder 0.4%, yucca extract 0.3%, mannan oligosaccharides 0.28%, rosemary Extract 0.22%, fructooligosaccharide 0.2%, t...

Embodiment 2

[0036] Example 2, see Figure 1-Figure 2 ,

[0037] S1: Raw material processing: use qualified meat raw materials, and the meat used has been treated with enzymatic hydrolysis to generate small molecular polypeptides.

[0038] S2: Granule preparation: crush and pre-mix the dry raw materials, add meat, vegetables and water, and then puff them into shapes. The puffing mold is used to make a circular shape with holes. After drying, it is mixed evenly with oil, enzymatically hydrolyzed chicken liver, and chicken liver powder. After cooling, add minced chicken breast and mix evenly. The mass percentage of added raw materials is as follows: 28% chicken, 17% squab, 16% chicken powder, 8% potato, 10% oil, 5% fish meal, 7% fruit and vegetable, and 2.15% egg %, beer yeast powder 1.5%, alfalfa granules 3%, vitamins and minerals 1.1%, postbiotic microcapsules 0.4%, spirulina powder 0.4%, yucca extract 0.3%, mannan oligosaccharides 0.28%, rosemary Extract 0.22%, fructooligosaccharide 0.2...

Embodiment 3

[0040] Example 3, see Figure 1-Figure 2 ,

[0041] S1: Raw material processing: use qualified meat raw materials, and the meat used has been treated with enzymatic hydrolysis to generate small molecular polypeptides.

[0042] S2: Granule preparation: crush and pre-mix the dry raw materials, add meat, vegetables and water, and then puff them into shapes. The puffing mold is used to make a circular shape with holes. After drying, it is mixed evenly with oil, enzymatically hydrolyzed chicken liver, and chicken liver powder. After cooling, add minced chicken breast and mix evenly. The mass percentage of raw materials added is as follows: 32% chicken, 18% squab, 12% chicken powder, 8% potato, 7% oil, 9% fish meal, 6.15% fruit and vegetable, and 1 egg %, beer yeast powder 1.5%, alfalfa granules 1%, vitamins and minerals 1.1%, postbiotic microcapsules 0.4%, spirulina powder 0.4%, yucca extract 0.3%, mannan oligosaccharides 0.28%, rosemary Extract 0.22%, fructooligosaccharide 0.2%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com