Fire extinguishing system for main transformer

A technology for main transformers and fire protection systems, applied in transformer/inductor components, transformer/inductor cooling, electrical component structure associations, etc., can solve problems such as inability to quickly control fires, increase image acquisition range, increase Fire extinguishing efficiency, the effect of improving the fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

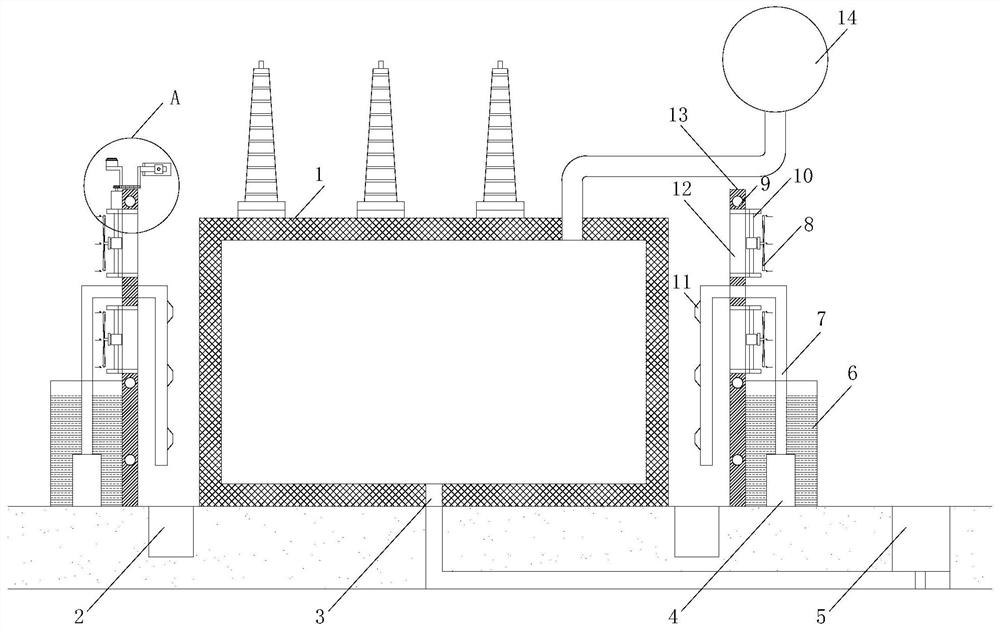

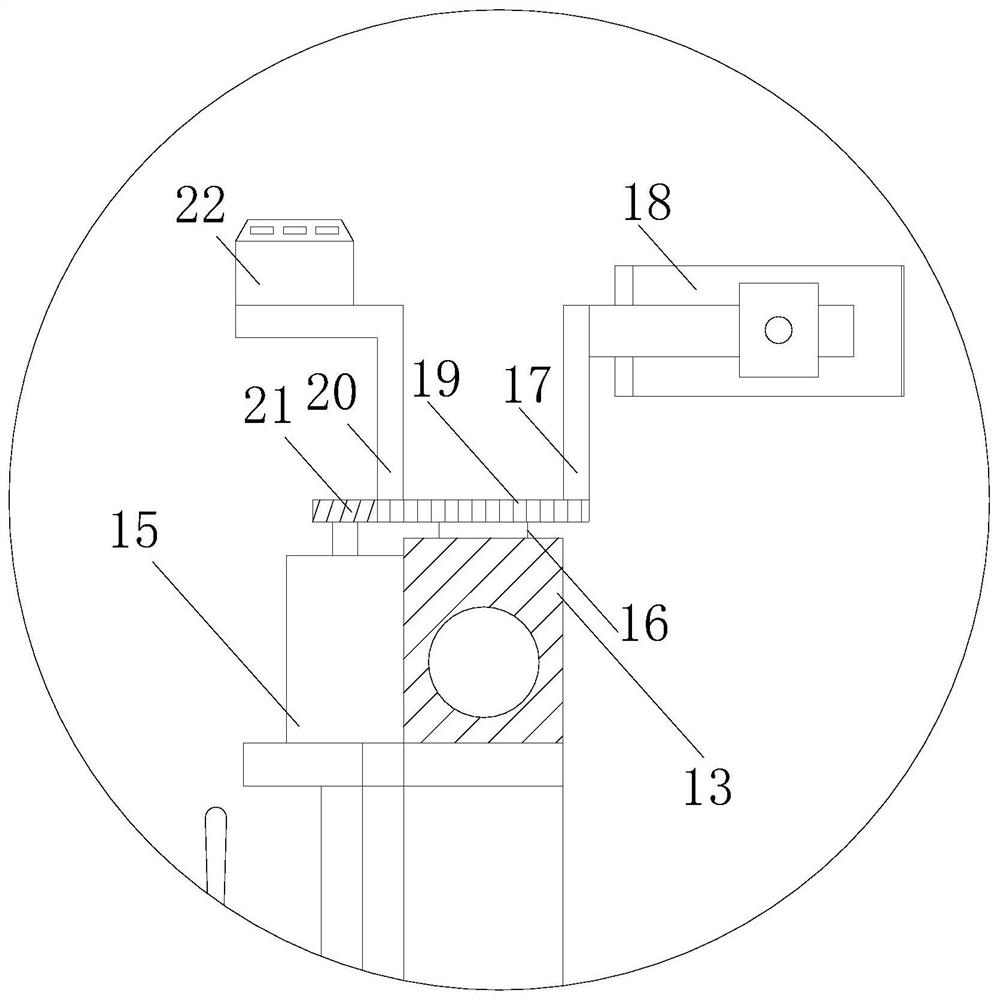

[0042] Such as Figure 1~6 As shown, it shows a specific embodiment of the present invention, as shown in the figure, the fire protection system of the main transformer of the present invention includes fixed fire protection components arranged on the left and right sides of the transformer body 1; the left and right sides and the front and rear sides are for It is easy to distinguish; it can be set on both sides, and the technical solution and technical purpose of the present invention can be realized at the same relative position; preferably, the front and rear sides are the side containing the transformer oil conservator 14 and the corresponding side, The left and right sides are the other two sides; this setting is more conducive to the heat dissipation of the cooling fan on the cooling wall;

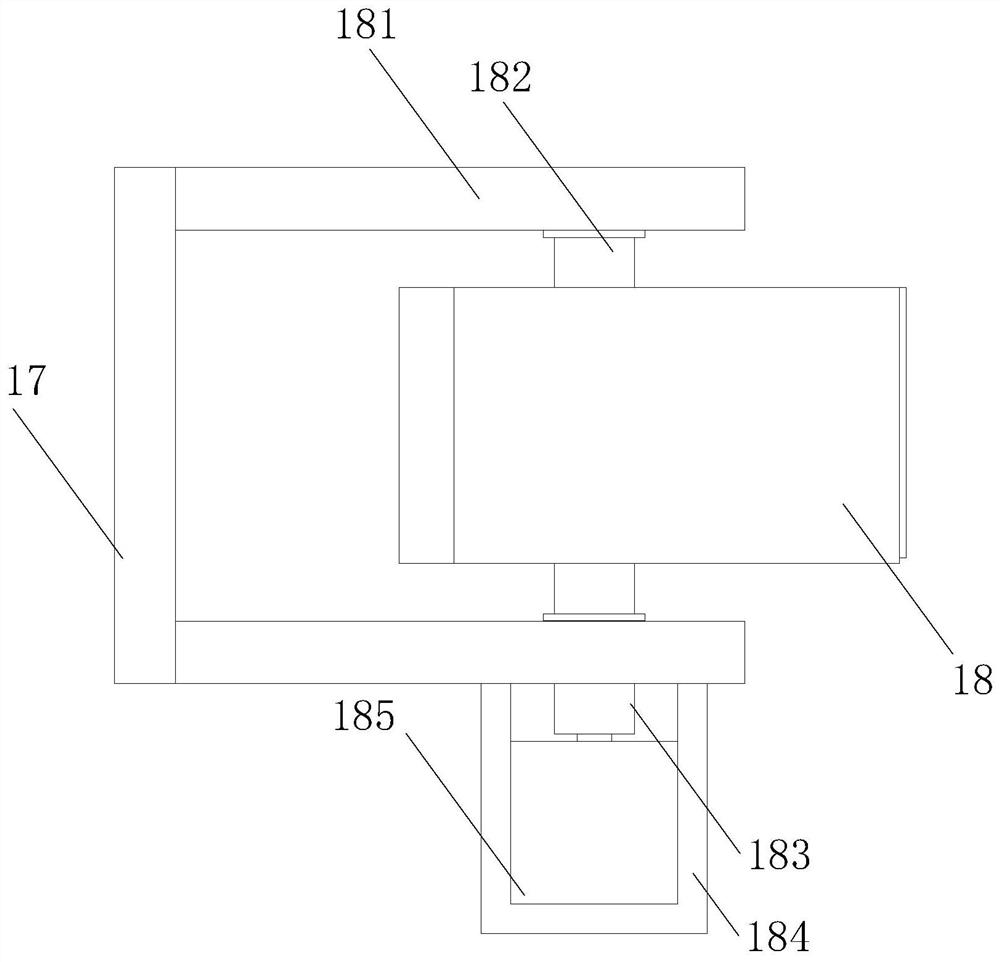

[0043] The fixed fire-fighting assembly includes a cooling wall 13, on which cooling fans 8 are evenly distributed; cooling water pipes 9 are arranged on the cooling wall 13; the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com