Building template waste removing equipment

A technology for building formwork and waste, applied in the direction of grain processing, etc., can solve the problems of low efficiency of building formwork waste removal, affecting construction progress, and single execution function, so as to reduce motion friction, improve crushing efficiency, and improve removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make a further detailed description of the invention, the present invention will be described in more detail below with reference to the technical solutions of the present invention, and the embodiments of the present invention are not limited thereto.

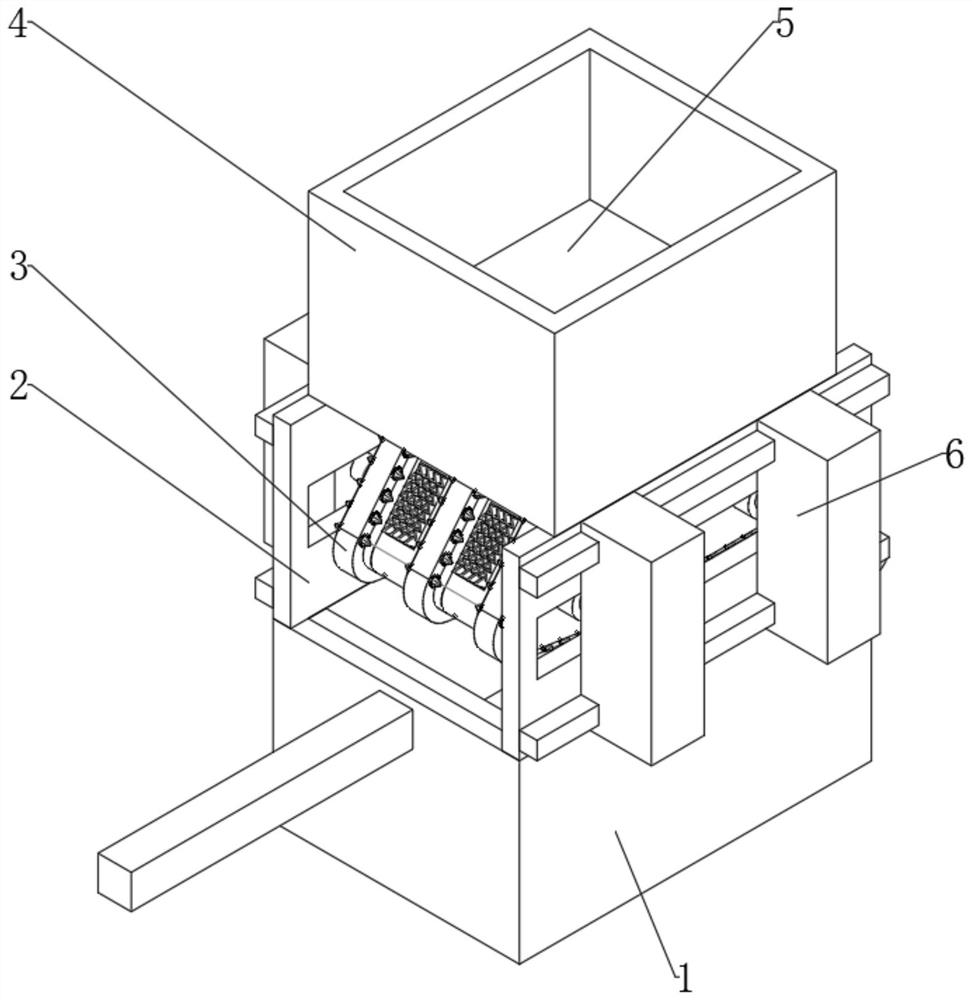

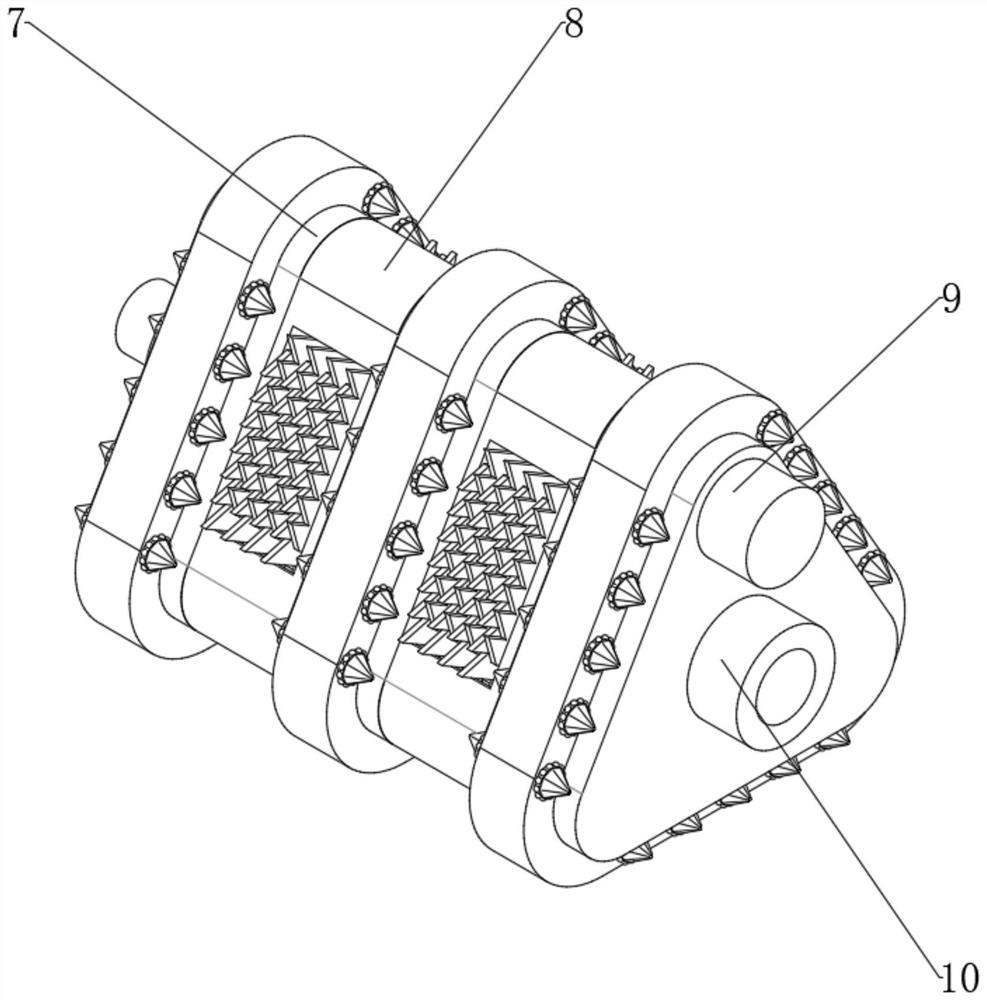

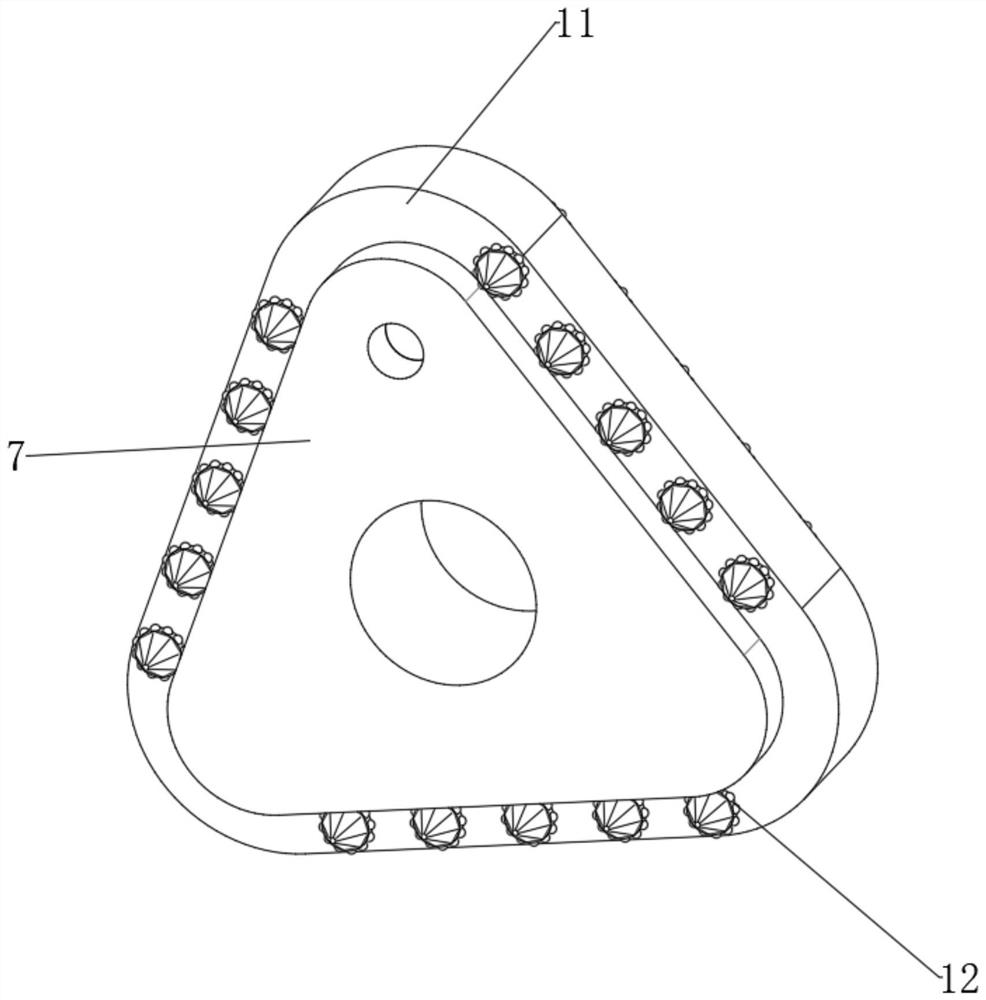

[0029] like Figure 1 - Figure 9 As shown, the construction template waste cleaning apparatus provided in this embodiment includes a silo 1 and two sets of adjustment assemblies disposed therefrom, and two sets of matrix mechanisms 3 are disposed between the two sets of adjustment components, and the mill mechanism 3 includes The spindle cylinder 10 and the turret 25 rotatably coupled thereto, the outer wall of the main sleeve 10 is provided with three sets of conductive assemblies and two sets of broken assemblies mounted between space, including the broken cylinder 8 fixed to the outer wall of the main sleeve 10 The three movable plates 16 on which the movable plate 16 is attached to the outer wall of the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com