Wiping device used after wafer cleaning

A post-cleaning, wafer technology, used in cleaning methods and utensils, removing smoke and dust, cleaning flexible objects, etc., can solve the problems of inability to ensure the cleanliness of wafer wiping, no two-way blowing and suction, and reducing airflow utilization. The effect of avoiding physical contact wiping, saving power and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

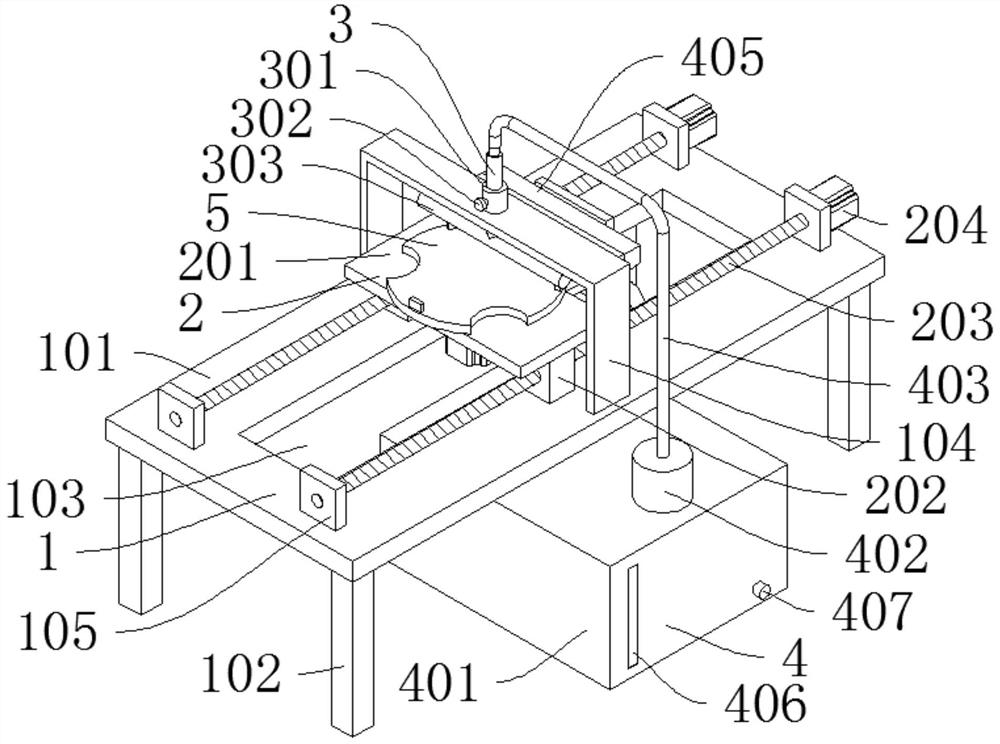

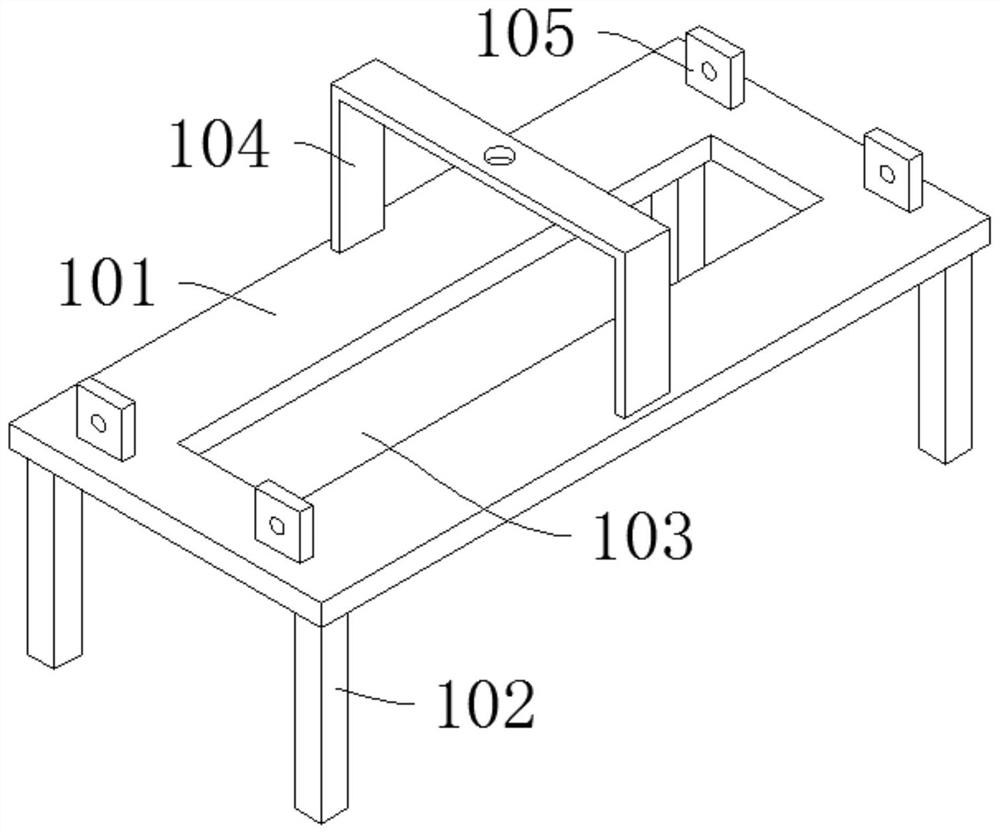

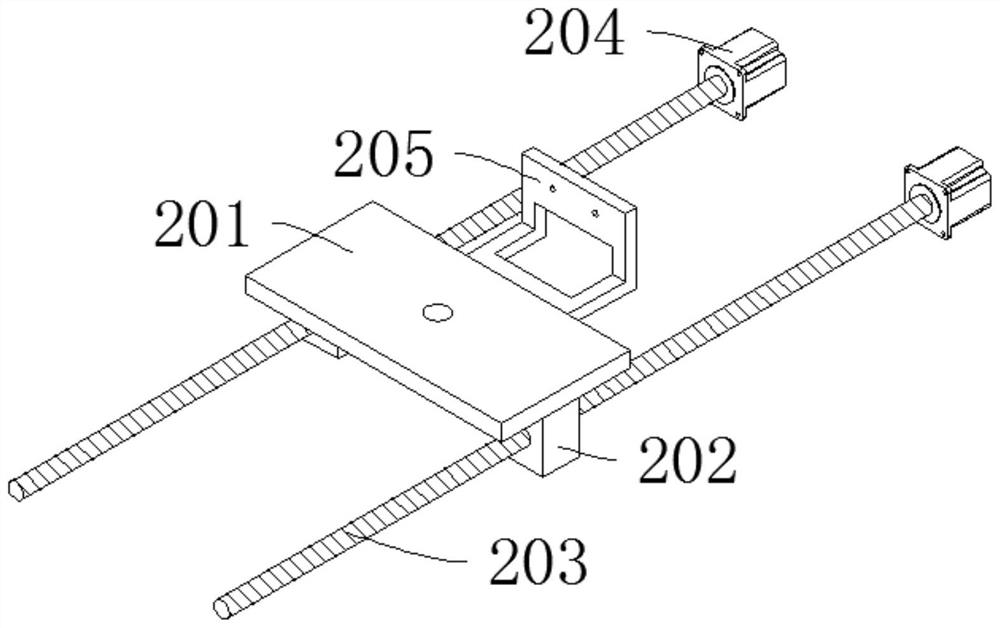

[0045] Such as Figure 1-Figure 7As shown, a wiping device after wafer cleaning includes a rack device 1 for support, and a translation device 2 for reciprocating movement. A clamping device 5 for fixing the rotation of the wafer is installed on the translation device 2 , the rack device 1 is equipped with an air spray device 3 for spraying air to wipe the surface of the wafer, and the rack device 1 is provided with a circulation device 4 for sucking air and water droplets below the rack device 1; Four support legs 102 are evenly distributed at the four corners of the bottom, four support plates 105 are evenly distributed at the four corners of the support platform 101, an avoidance groove 103 is arranged in the middle of the support platform 101, and a fixed frame 104 is arranged above the avoidance groove 103; Plate 201, two nut blocks 202 are symmetrically installed on the bottom of the supporting plate 201, a lead screw 203 is installed in the middle of the screw block 202...

Embodiment 2

[0048] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the clamping device 5 includes a second motor 501, a swivel frame 505 is installed on the second motor 501, three clamping plates 503 are evenly distributed on the circumference of the swivel frame 505, and the swivel frame 505 The bottom plate is provided with a connecting sleeve 506, and the second motor 501 drives the swivel frame 505 through the connecting sleeve 506 to fix the wafer to rotate through the clamping plate 503; the connecting sleeve 506 and the rotary frame 505 are welded together, and the clamping plate 503 and the rotary frame 505 are riveted together. Welding ensures that the connecting sleeve 506 is strong and firm, and riveting ensures that the clamping plate 503 is stable and reliable.

[0049] Working principle: slide the T-shaped tube 303 up and down in the support sleeve 301, adjust the height of the nozzle 304, and tighten the locking nail 302 to fix it, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap