Low-temperature heat-sealing paperless carton cigarette outer packaging film processing technology and processing device

A technology of outer packaging film and low-temperature heat sealing, which is applied in the field of packaging film processing, can solve the problems of low stirring efficiency, uneven mixing, single stirring rod, etc., and achieve the effect of flexible use, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

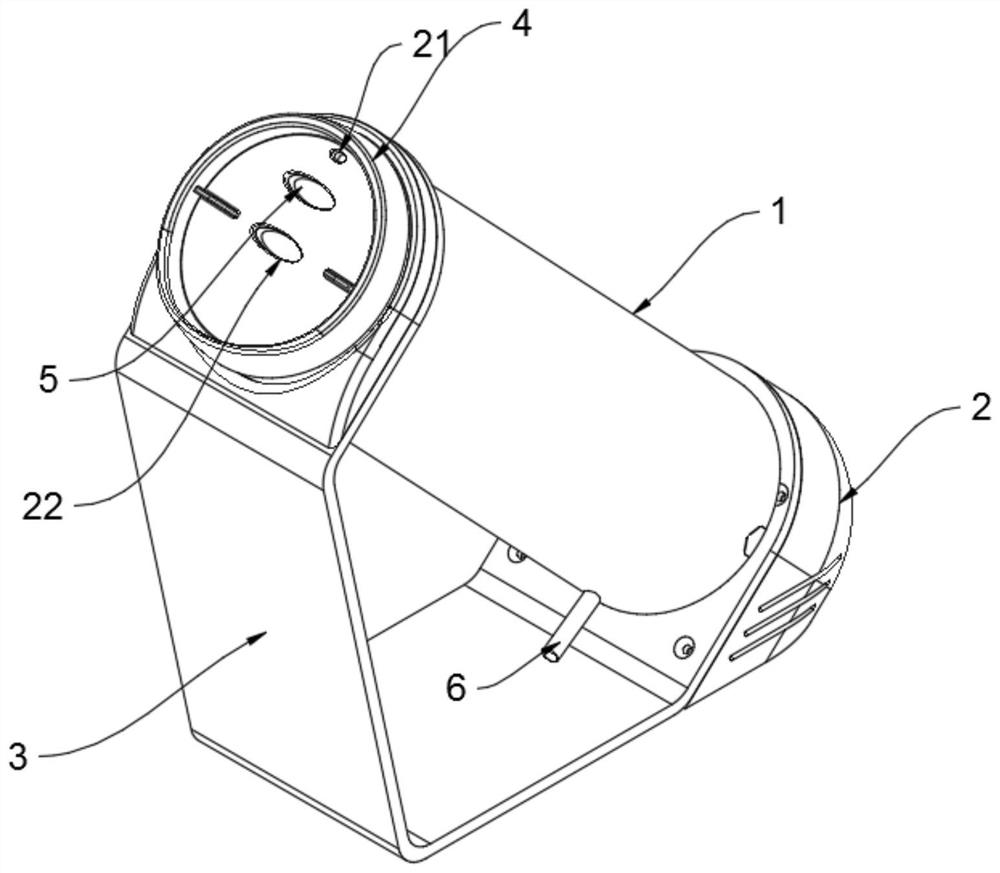

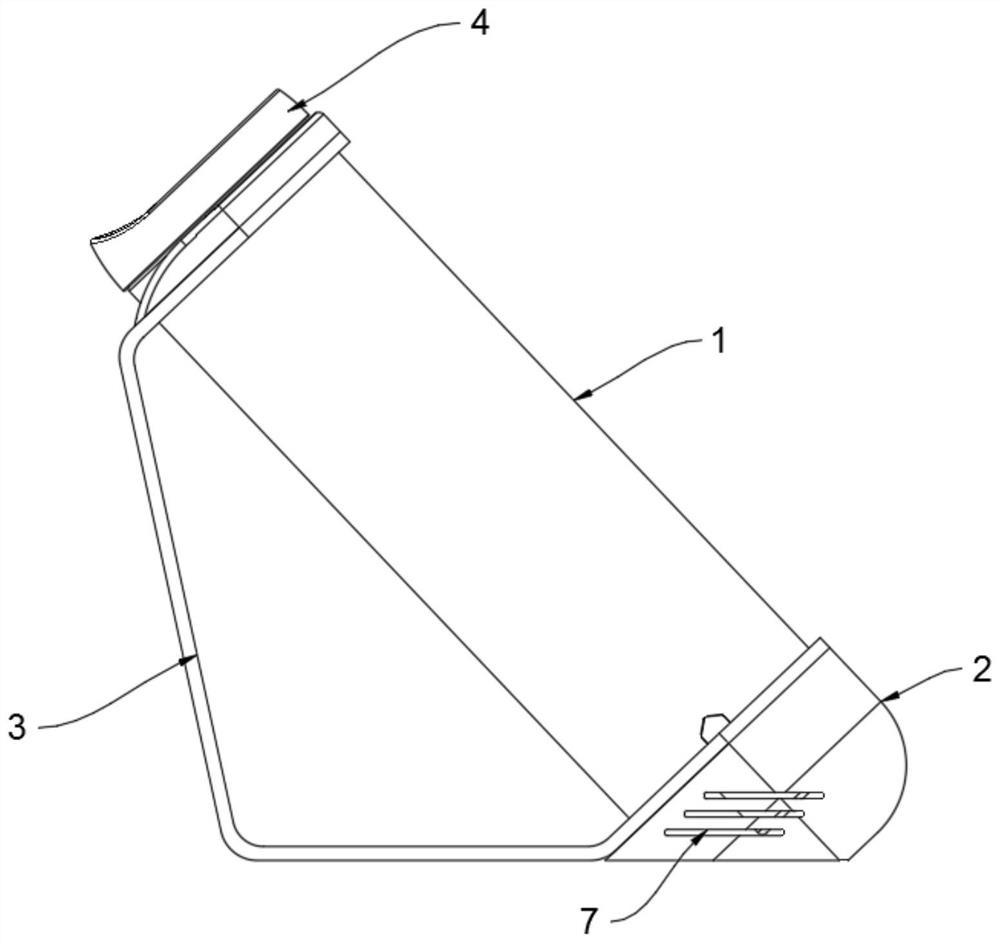

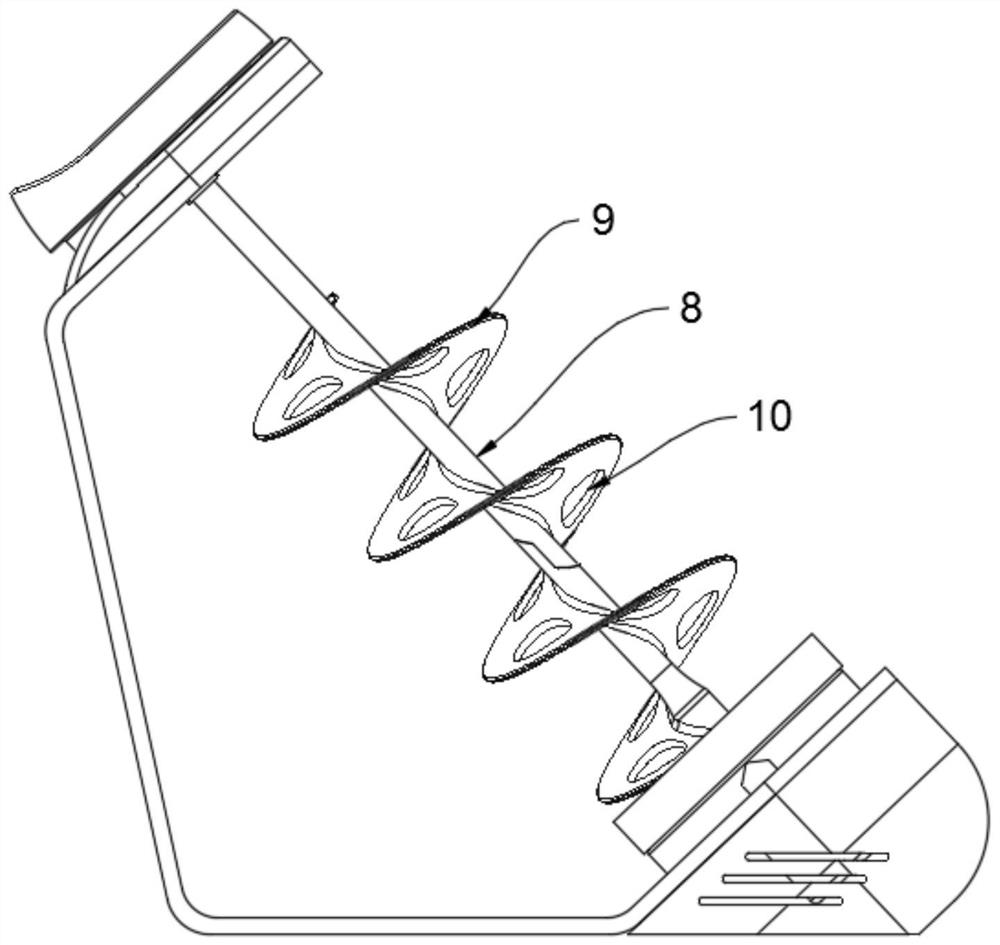

[0027] Such as figure 1 , figure 2 and image 3 As shown, a low-temperature heat-sealing paperless cigarette outer packaging film processing device, the device includes a carrying barrel 1, the carrying barrel 1 is inclined, the lower end of the carrying barrel 1 is connected with a carrying seat 2, the carrying The outer surface of the barrel 1 is fixedly connected with a carrier frame 3, and the upper end of the carrier barrel 1 is detachably connected with a sealing cap 4, and the outer surface of the sealing cap 4 is provided with a filling port 5, a feeding port 22 and an air outlet 21, The filling port 5, the feeding port 22 and the air outlet 21 are all connected to a sealing cap, and the outer surface of the carrying bucket 1 is fixedly connected with a discharge pipe 6, and the discharge pipe 6 is arranged on the inclined side of the carrying bucket 1. At the lowest position, a valve member is arranged in the discharge pipe 6, a driving motor is arranged inside the...

Embodiment 2

[0034] A low-temperature heat-sealing paperless cigarette outer packaging film processing process, the process includes a processing device, the processing device includes a carrying barrel 1, the carrying barrel 1 is inclined, and the lower end of the carrying barrel 1 is connected to a carrying seat 2. The upper end of the carrying barrel 1 is detachably connected with a sealing cap 4, and the outer surface of the sealing cap 4 is provided with a filling port 5, a feeding port 22 and an air outlet 21, and the filling port 5, the feeding port 22 The air outlet 21 is connected with a sealing cap, the outer surface of the carrying bucket 1 is fixedly connected with a discharge pipe 6, and the discharge pipe 6 is arranged at the lowest position of the inclination of the carrying bucket 1, and the inside of the discharge pipe 6 is A valve is provided, and a driving motor is arranged inside the bearing seat 2, and the driving end of the driving motor is connected with a stirring ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com