Biological fermentation tank with uniform material distribution

A technology of biological fermenter and uniform distribution, which is applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biomass post-processing, etc. Poor quality and other problems, to achieve the effect of improving judgment accuracy, improving practicability and market competitiveness, and facilitating sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

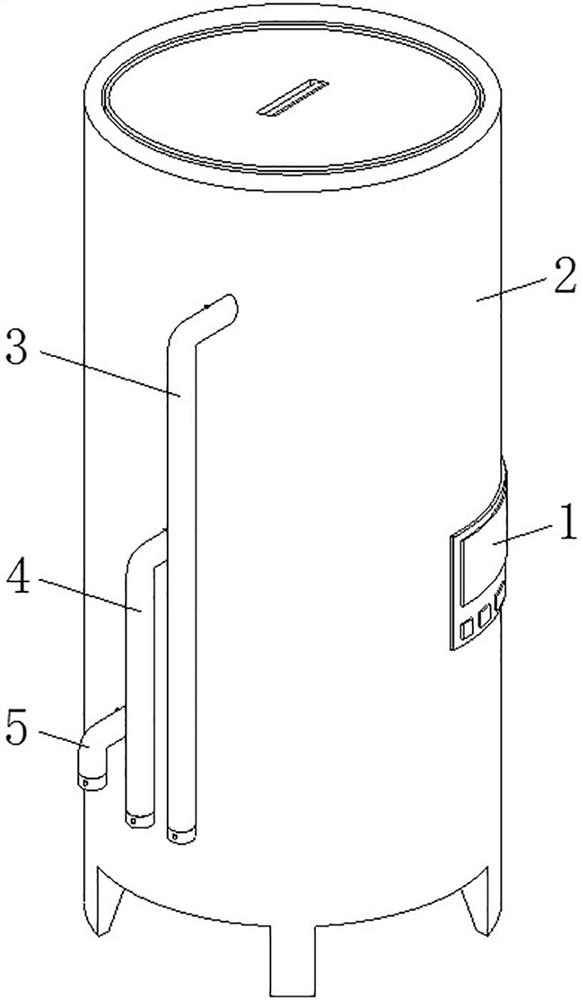

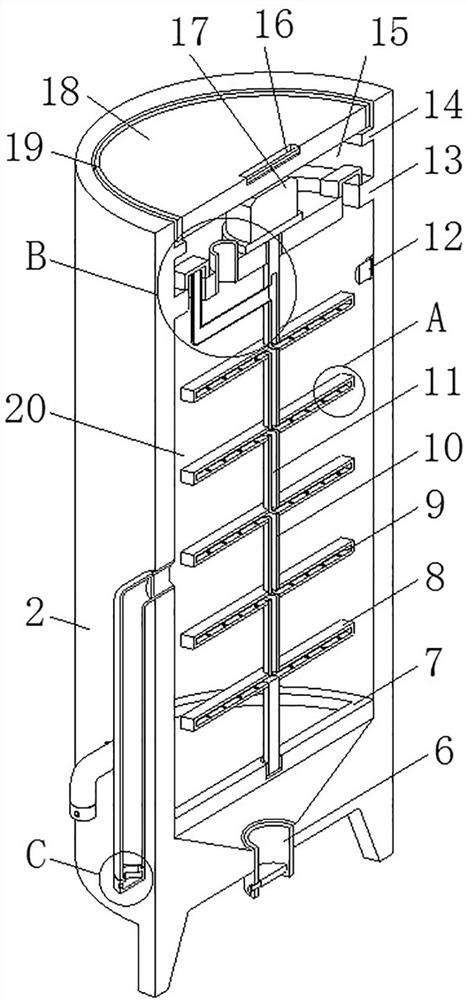

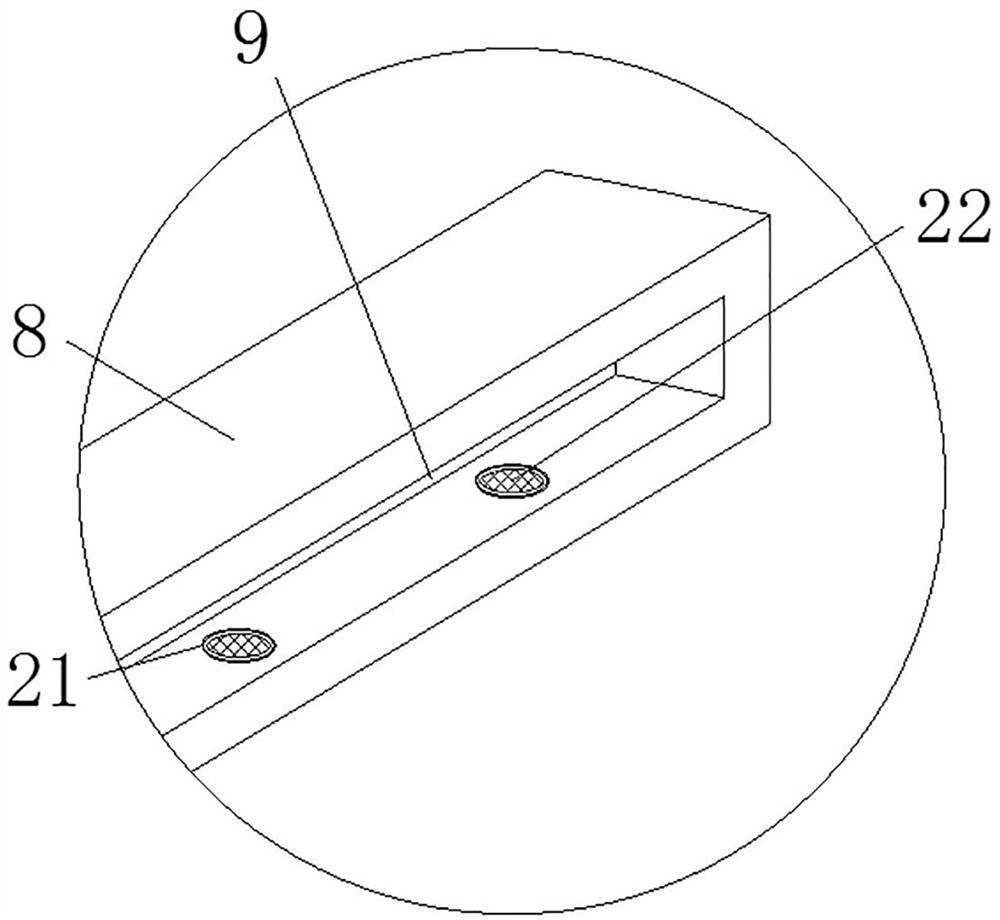

[0025] see Figure 1-5 , the present invention provides the following technical solutions: a uniformly distributed biological fermentation tank, comprising a biological fermentation tank body 2, the outer wall of the biological fermentation tank body 2 is equipped with a controller 1, and the interior of the biological fermentation tank body 2 is provided with a partition structure, The inside of the biological fermentation tank 2 is provided with an operation cavity 15 above the partition structure, and a feed port 24 is connected to the partition structure and located in the operation cavity 15, and the inner wall of the operation cavity 15 is located at the feed port. 24 is connected with a support plate 14, a cover 18 is provided in the operating cavity 15 and above the support plate 14, the top of the cover 18 is provided with a recessed handle 16, and the outer side of the cover 18 is provided with The sealing ring 19, the inside of the biological fermentation tank 2 and...

Embodiment 2

[0037] The difference of this embodiment compared with embodiment 1 is:

[0038] Specifically, the outer wall of the biological fermentation tank 2 is sequentially connected with the highest sampling tube 3, the middle sampling tube 4 and the lowest sampling tube 5 from front to back, and the heights of the highest sampling tube 3, the middle sampling tube 4 and the lowest sampling tube 5 are in order Decrease, the highest sampling pipe 3, the middle sampling pipe 4 and the lowest sampling pipe 5 are all equipped with control valves.

[0039] During the biological fermentation process, the fermentation personnel can sample and analyze the fermentation products at the highest height, middle height and lowest height in the biological fermentation chamber 20 respectively through the highest sampling tube 3, the middle sampling tube 4 and the lowest sampling tube 5, so as to improve the judgment of the fermentation personnel. The accuracy of the degree of fermentation of the ferme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap