A prefabricated energy dissipation structure system and design method with separation of gravity and lateral force

A design method and prefabricated technology, applied in the direction of building components, building structures, protected buildings/shelters, etc., can solve the problems of standardized design and production of inconvenient components, high cost, complex structure, etc., and achieve improved seismic safety high performance, simple node structure, and the effect of improving energy dissipation and shock absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

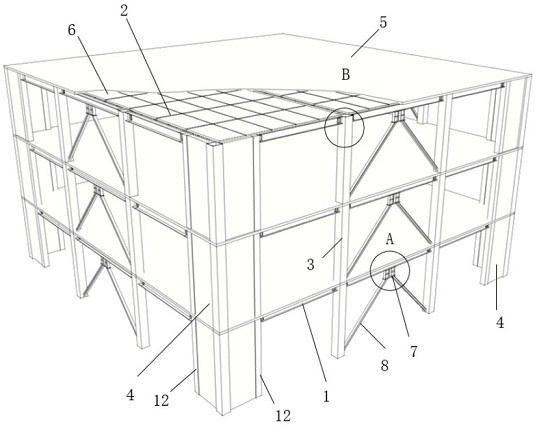

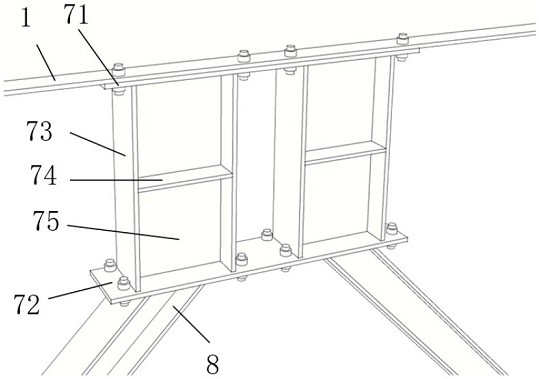

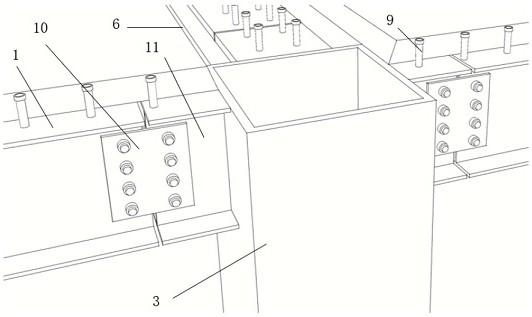

[0036] Such as Figure 1~Figure 6 As shown, this embodiment provides a prefabricated energy-dissipating structural system that separates gravity and lateral force, including a prefabricated shear wall 4 and a frame column 3, and the prefabricated shear wall 4 is arranged at the center of the prefabricated energy-dissipating structural system around the corners to enhance the overall torsional rigidity of the fabricated energy-dissipating structural system. The main beam 1 is installed between the adjacent prefabricated shear wall 4 and the frame column 3, the main beam 1 is installed between the adjacent frame column 3 and the frame column 3, and the main beam 1, the prefabricated shear wall The secondary beam 2 is installed on the floor layer perpendicular to the prefabricated shear wall 4 formed by the wall 4 and the frame column 3 , a metal damper 7 is installed in the middle span of the main beam 1 , and a support 8 is arranged below the metal damper 7 . Concrete prefabri...

Embodiment 2

[0042] Such as Figure 7~Figure 9 As shown, the prefabricated shear wall 4 is arranged between adjacent frame columns 3 , and edge restraint members 12 are arranged on both sides of the prefabricated shear wall 4 .

[0043] A corbel 11 is reserved at the joint between the prefabricated shear wall 4 and the main beam 1 .

Embodiment 3

[0045] Such as Figure 10 As shown, this embodiment provides a design method for a prefabricated energy-dissipating structural system that separates gravity from lateral force. The design method is used to design a prefabricated energy-dissipating structural system that separates gravity from lateral force. The design method includes:

[0046] S100, determine the design scheme of main girder 1, secondary girder 2 and laminated slab composite floor 5;

[0047] According to the vertical gravity load given by the design conditions, the reinforcement of the laminated slab composite floor 5 is designed to ensure that the bearing capacity and stiffness meet the specification requirements, and the size of the concrete precast slab 6 is designed;

[0048] Design the cross-sectional dimensions of main beam 1 and secondary beam 2 according to simply supported composite beams, and the design value of mid-span bending moments of composite beams and the design value of the shear force of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com