Replaceable assembled type energy dissipating and vibration damping joint provided with self resetting function

A prefabricated, self-resetting technology, applied in protective buildings/shelters, building components, building structures, etc., can solve the problem of changing structural dynamic energy consumption plastic hinge areas, poor energy dissipation and vibration reduction capabilities, and replaceable functions Improve the ease of implementation and recovery, improve performance, and improve energy dissipation and shock absorption capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

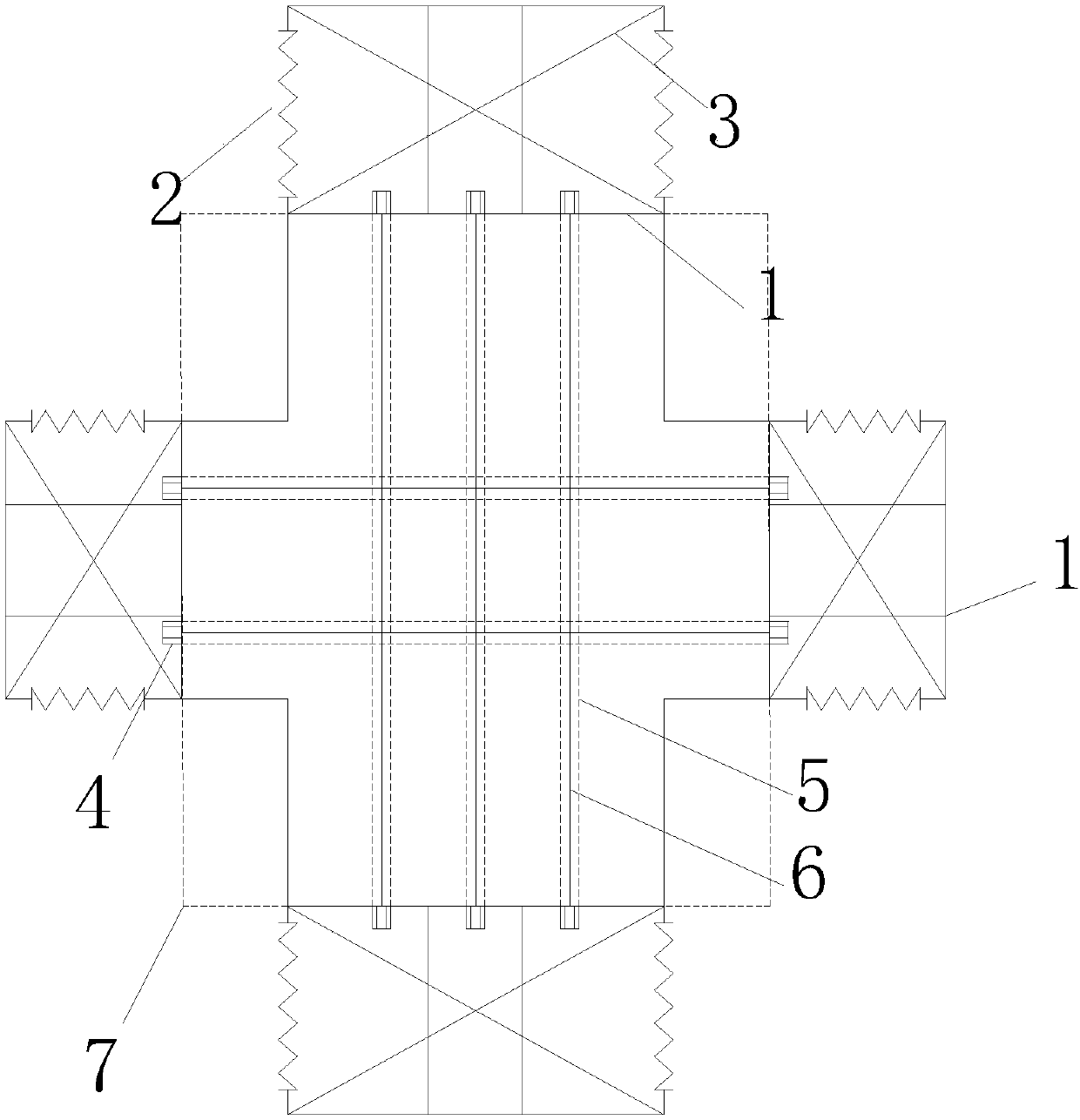

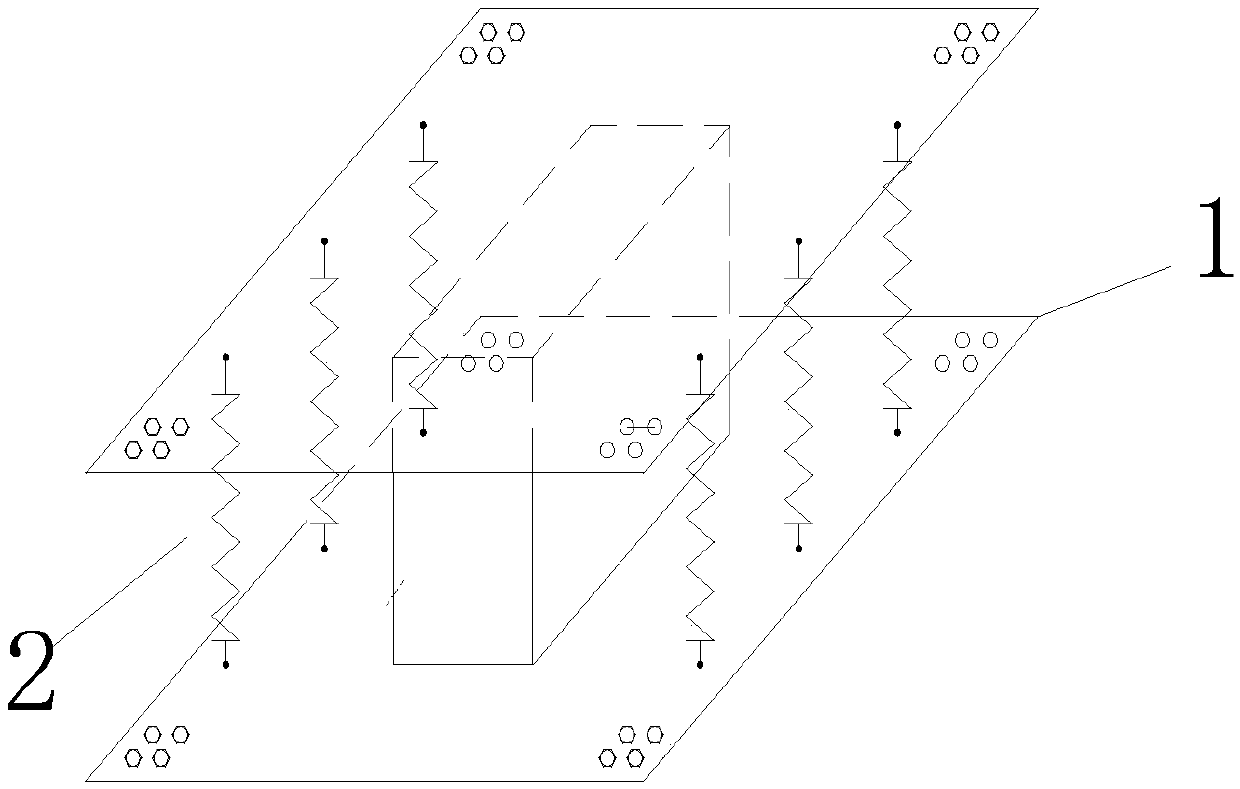

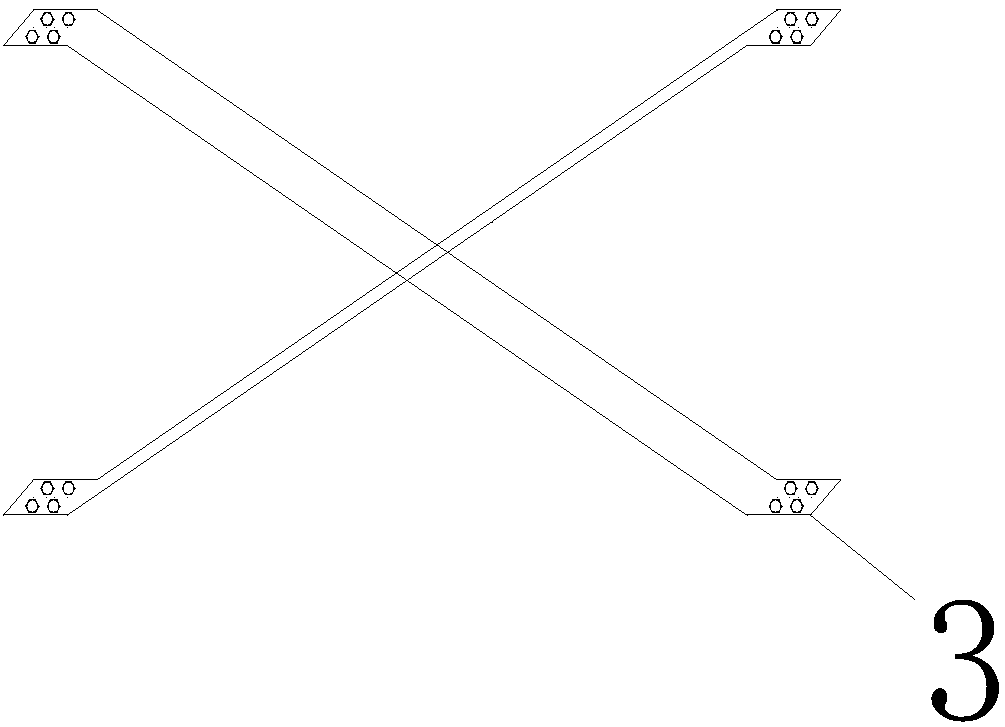

[0028] Such as Figure 1 ~ Figure 4 As shown, it is a replaceable assembled energy-dissipating and vibration-reducing joint with self-resetting function of the present invention, which mainly includes energy-dissipating and resetting function connecting plate 1, self-resetting spring 2, energy-dissipating mild steel 3, and high-strength anchor bolts 4. Prefabricated reserved channels 5, prestressed tendons 6, and node core areas 7. This node is used for prefabricated beam members in the prefabricated frame structure of the building.

[0029]Energy dissipation and reset function connecting plate 1 is long flange I-shaped steel, flange plate and web (box section) are connected by welding, its cross-sectional size is b400mm×h500mm, Q420 steel is used, the upper and lower flange plates on the flange plate Set up six reserved channels 5 connected with prestressed tendons and anchor bolt holes connected with four pairs of energy-dissipating soft steel 3, and set six pre-installed c...

Embodiment 2

[0036] Such as Figure 1 ~ Figure 4 As shown, it is a replaceable assembled energy-dissipating and vibration-reducing joint with self-resetting function of the present invention, which mainly includes energy-dissipating and resetting function connecting plate 1, self-resetting spring 2, energy-dissipating mild steel 3, and high-strength anchor bolts 4. Prefabricated reserved channels 5, prestressed tendons 6. This node is used at the end of fabricated bridge pier column members.

[0037] This node does not set the core area 7, which is used as the plastic hinge area at the end of the prefabricated bridge pier column. Energy dissipation and reset function connecting plate 1 is long flange I-shaped steel, forged, its cross-sectional size is b600mm×h600mm, and Qd420 steel is used. Reserve holes 5 and anchor bolt holes connected to eight pairs of energy-dissipating mild steel 3, and set four pre-compressed self-resetting springs 2 symmetrically by welding at the four corners of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com