Virtual power plant rolling scheduling technology considering temperature control load polymer

A technology for temperature-controlled loads and virtual power plants, applied in AC network voltage adjustment, information technology support systems, photovoltaic power generation, etc. Practical value, improved universality, and efficient computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

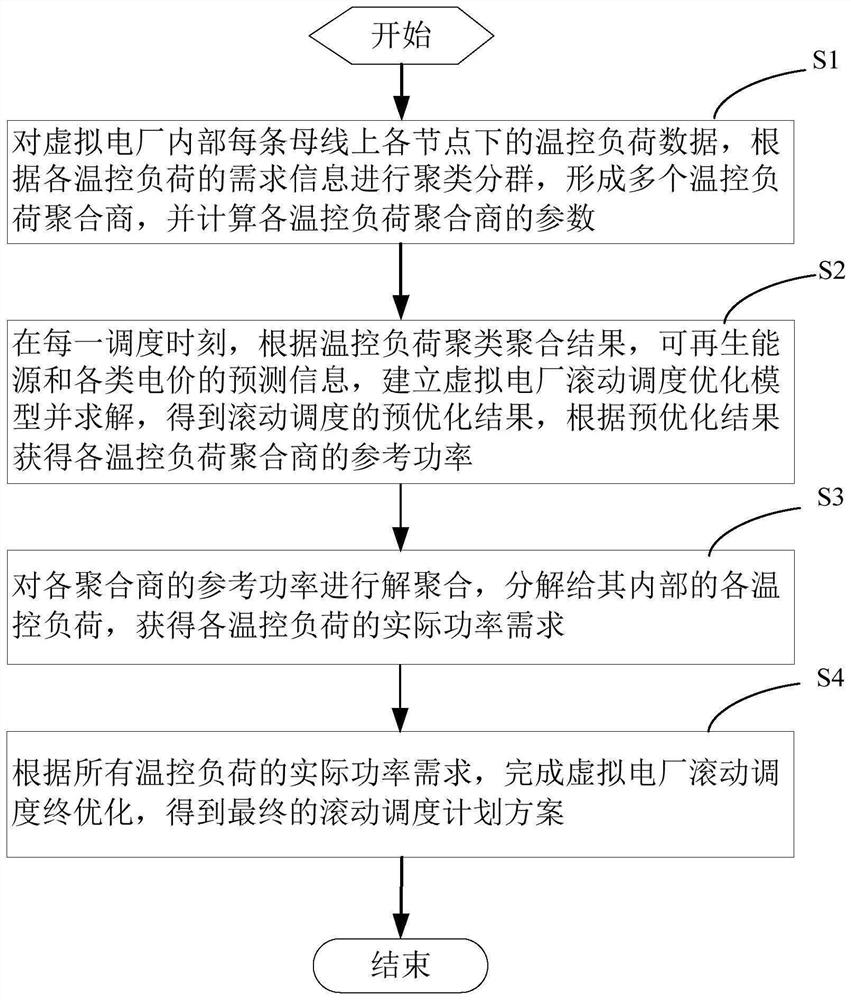

[0108] like figure 1 As shown in FIG. 1 , it shows a schematic diagram of the main flow of an embodiment of a virtual power plant rolling scheduling method considering temperature-controlled load aggregates provided by the present invention. In this embodiment, the method includes the following steps:

[0109] Step S1, cluster and group the temperature-controlled load data of each node on each bus in the virtual power plant according to the demand information of each temperature-controlled load, form multiple temperature-controlled load aggregators, and calculate each temperature-controlled load aggregator parameters;

[0110] In a specific example, the step S1 fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com