Stable diclofenac diethylamine gel plaster and preparation method thereof

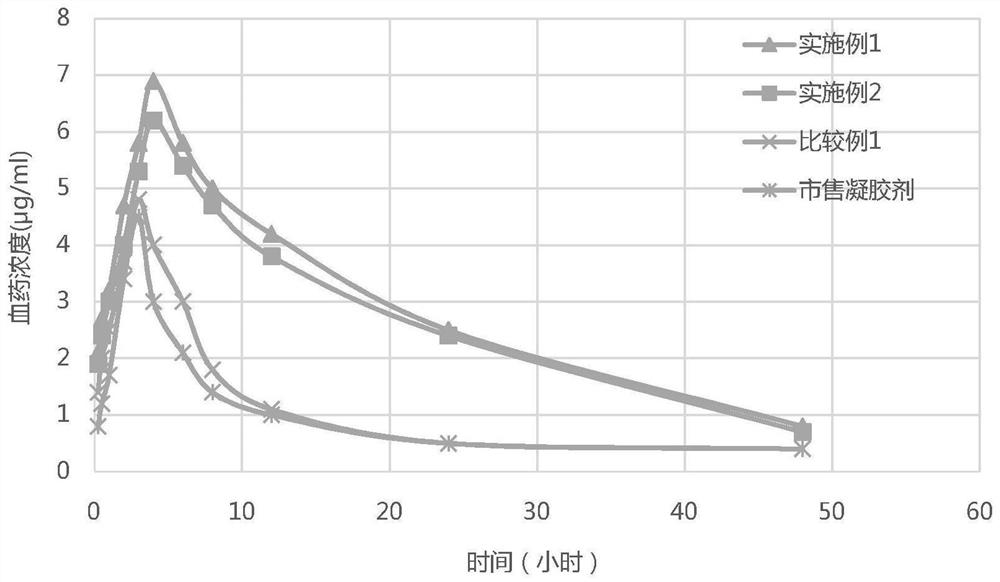

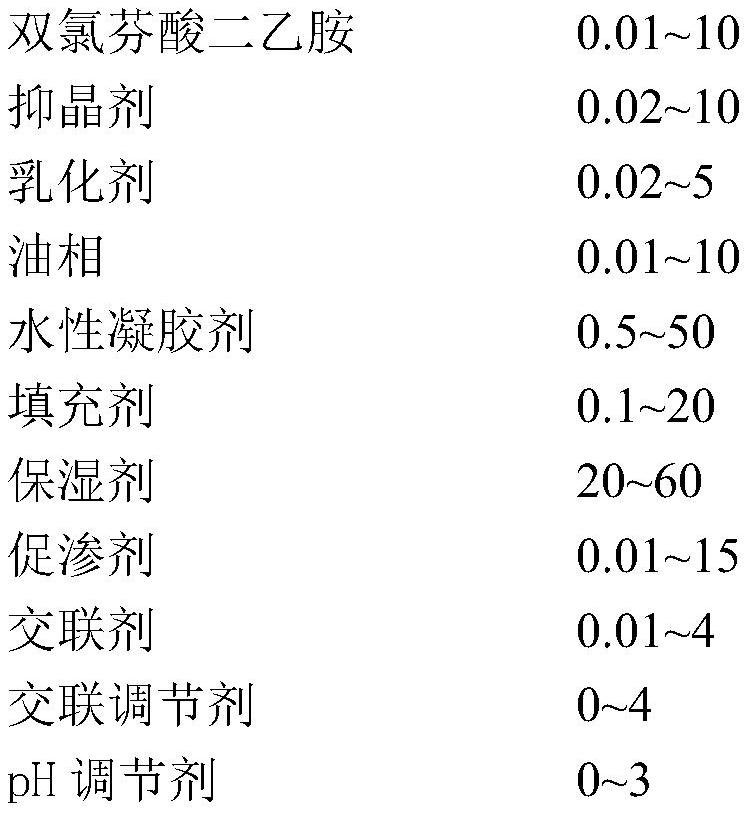

A technology of diclofenac diethylamine gel patch and diclofenac diethylamine, which is applied to medical preparations containing no active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve the problem of slow drug onset and skin penetration Poor sex resistance, poor skin compliance and other problems, to achieve the effect of improving skin permeability, high bioavailability, and increasing fat solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: use polyvinylpyrrolidone as crystal inhibitor

[0053]

[0054] making process:

[0055] a) Put diclofenac diethylamine, propylene glycol, liquid paraffin, caprylic acid / capric fatty alcohol ester in a container to heat, then put polyvinylpyrrolidone and an appropriate amount of purified water in the container to dissolve, then mix the two, and heat Stir homogeneously to make it emulsified to obtain an O / W emulsion.

[0056] b) Disperse sodium polyacrylate, aluminum glycolate, disodium edetate, kaolin, and menthol in the prescribed amount in glycerin, and then dissolve tartaric acid and methyl hydroxybenzoate in the remaining purified water.

[0057] c) Then add the O / W type emulsion into the above-mentioned glycerin dispersion, mix well, then quickly add the remaining purified water containing tartaric acid and methyl hydroxybenzoate, stir and mix evenly to obtain a medicated patch matrix layer.

[0058] d) Evenly apply the base layer of the plaster ...

Embodiment 2

[0059] Embodiment 2: use triethanolamine as decrystallizer

[0060]

[0061]

[0062] making process:

[0063] a) Put diclofenac diethylamine, propylene glycol, liquid paraffin, caprylic acid / capric fatty alcohol ester in a container and heat, then put an appropriate amount of purified water in the container and heat to dissolve, then mix the two, stir and homogenize under heating Make it emulsified, and finally add triethanolamine to obtain an O / W emulsion.

[0064] b) Disperse sodium polyacrylate, aluminum glycolate, disodium edetate, kaolin, and menthol in the prescribed amount in glycerin, and then dissolve tartaric acid and methyl hydroxybenzoate in the remaining purified water.

[0065] c) Then add the O / W type emulsion into the above-mentioned glycerin dispersion, mix well, then quickly add the remaining purified water containing tartaric acid and methyl hydroxybenzoate, stir and mix evenly to obtain a medicated patch matrix layer.

[0066] d) Evenly apply the b...

Embodiment 3

[0067] Embodiment 3: Use polyvinylpyrrolidone as a crystal inhibitor, but do not prepare the drug into an O / W type emulsion

[0068]

[0069] making process:

[0070] a) Take an appropriate amount of purified water to dissolve polyvinylpyrrolidone, then add diclofenac diethylamine and propylene glycol and heat to dissolve to form a drug solution.

[0071] b) Disperse sodium polyacrylate, aluminum glycolate, disodium edetate, kaolin, and menthol in the prescribed amount in glycerin, and then dissolve tartaric acid and methyl hydroxybenzoate in the remaining purified water.

[0072] c) Then the drug solution is added to the above-mentioned glycerin dispersion, mixed thoroughly, and then the remaining purified water containing tartaric acid and methyl hydroxybenzoate is quickly added, stirred and mixed evenly to obtain a drug-containing plaster matrix layer.

[0073] d) Evenly apply the base layer of the plaster containing the medicine on the polyethylene terephthalate PET fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com