Building waste mud sand washing production line

A construction waste and production line technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of sand residue, inability to realize sand washing, and inability to fish for sand, so as to achieve full sand washing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following is attached Figure 1-5 The application is described in further detail.

[0049] The embodiment of the present application discloses a sand washing system.

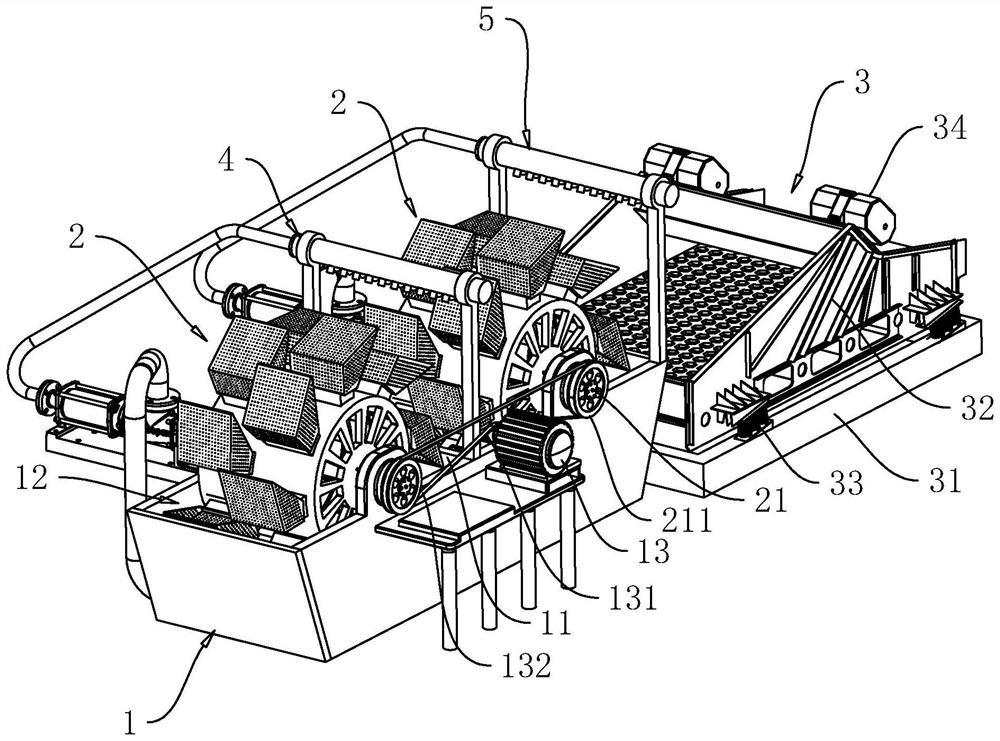

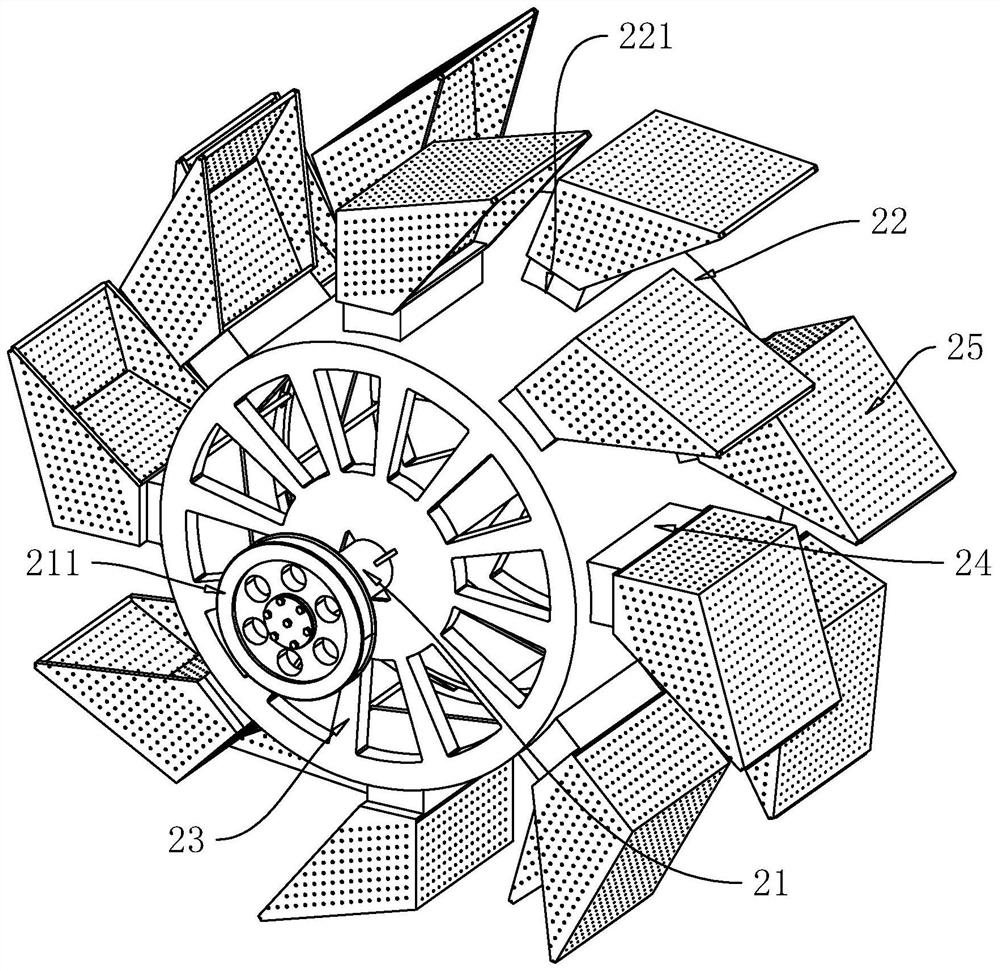

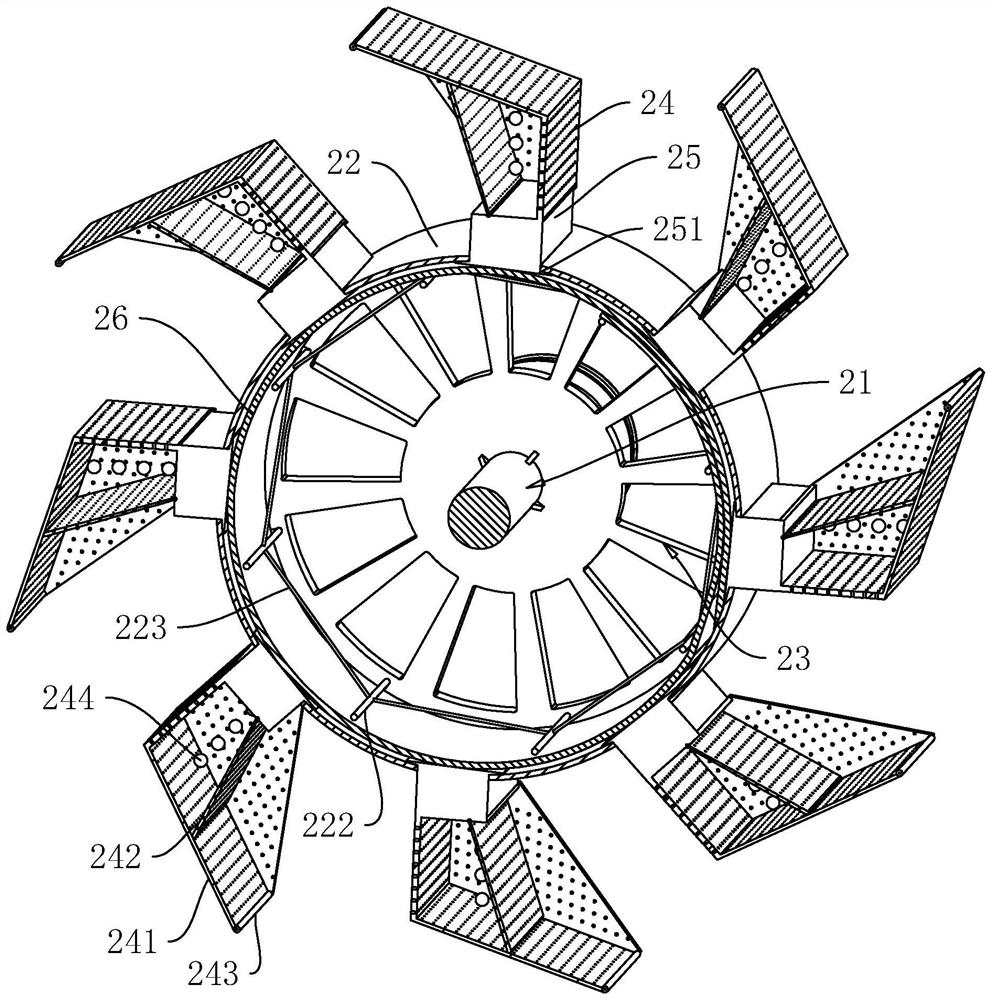

[0050] refer to figure 1 , Construction waste mud sand washing production line includes sand washing tank 1, two water washing wheels 2 arranged in sequence in sand washing tank 1, dewatering screen 3 set at the discharge end of sand washing tank 1, and two water washing wheels 2 arranged in sand washing tank 1 Between the spray frame one 4 and the spray frame two 5 that are arranged between the sand washing tank 1 corresponding to a water washing wheel 2 and the dewatering screen 3 . When working, inject water into the sand washing tank 1, through the rotation of the two water washing wheels 2, sand removal is realized, and then the removed sand is sent to the dehydration screen 3, and then sent out after dehydration and sieving, and the spray frame 4 Spray with the spray rack, realize the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com