An environment-friendly heating and drying device for composite wood floor gluing

A drying device and composite wood technology, which is applied to wood processing appliances, other plywood/plywood appliances, and the joining of wooden veneers. It can solve problems such as affecting quality, increasing the gap between boards, and overflowing glue. Enhance the flexibility and performance, increase the gap, and ensure the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0029] Such as Figure 1-Figure 5 As shown, the present invention provides a technical scheme of an environment-friendly composite wood floor gluing heating and drying device:

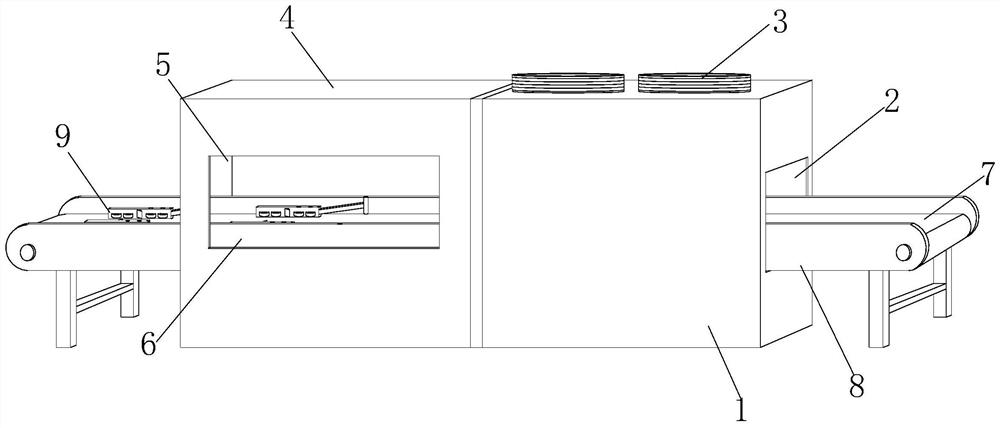

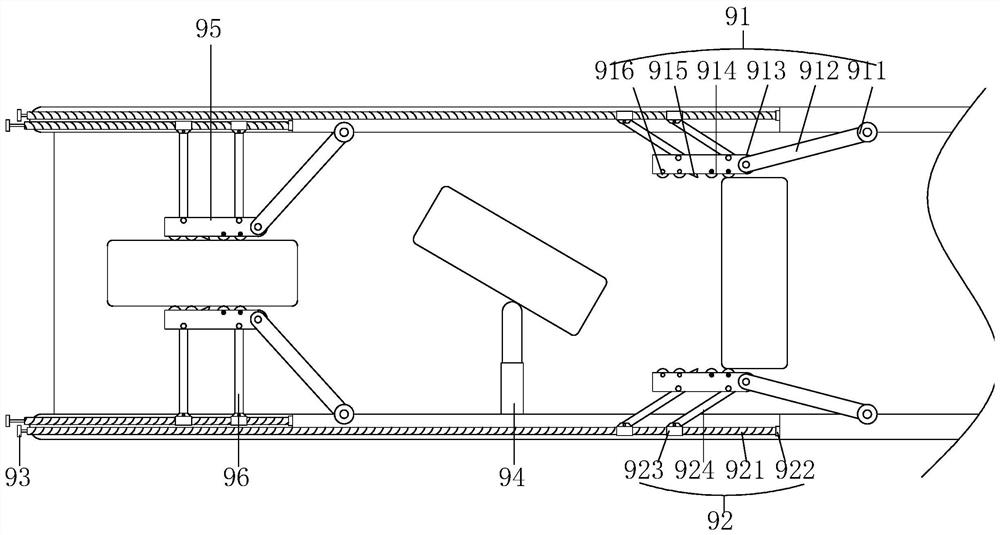

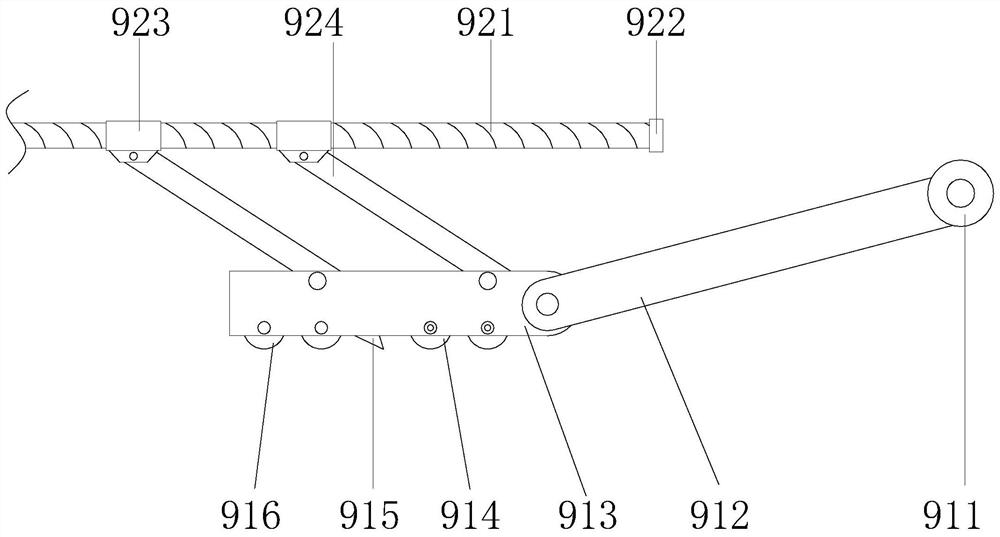

[0030] Such as figure 1 As shown, an environment-friendly heating and drying device for composite wood floor gluing, its structure includes a drying machine box 1, a delivery inlet 2, a moisture removal system 3, a scum scraper box 4, a delivery outlet 5, a visual window 6, Conveying device 7, anti-falling side plate 8, adjustable board edge rubber residue scraping device 9, the delivery port 2 is set on the right side of the drying machine box 1, and the moisture removal system 3 is set on the top of the drying machine box 1. The scum scraping box 4 is located on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com