Drilling equipment for petroleum valve accessories

A technology of drilling equipment and valves, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., which can solve the problems of manpower consumption, falling off, danger, etc., to avoid unstable falling, stable Sliding seat, convenient positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

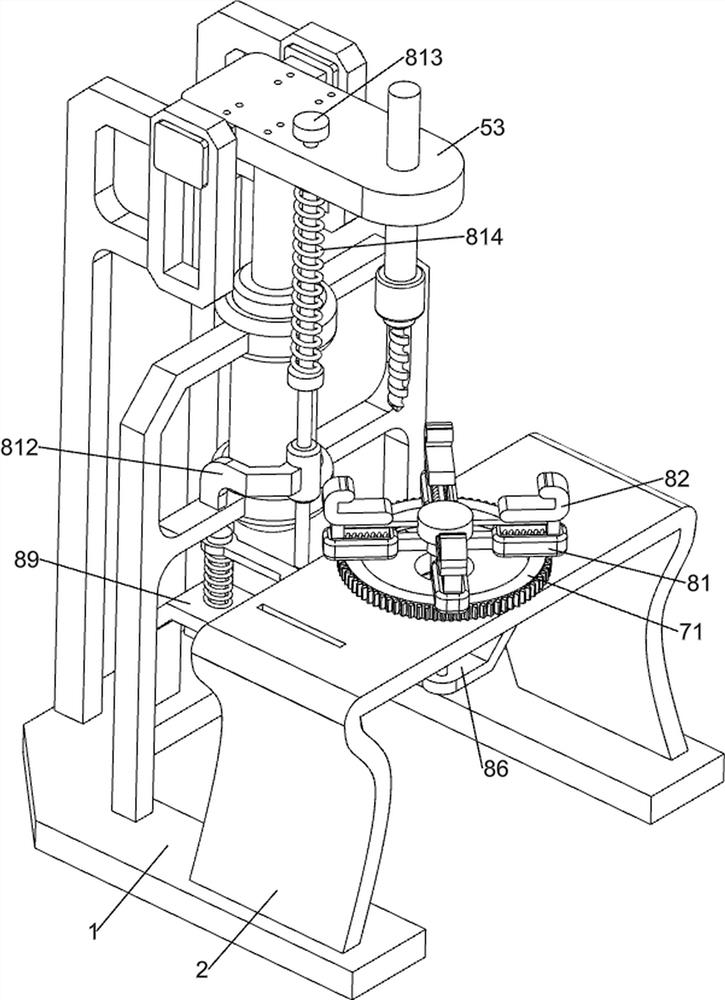

[0027] Such as figure 1 and figure 2 As shown, this embodiment discloses a drilling equipment for petroleum valve accessories, including a base 1, a workbench 2, an installation shaft 3, a drill bit 4, a lifting mechanism 5 and a driving mechanism 6, and the upper front side of the base 1 is connected to a workbench 2. A lifting mechanism 5 is provided on the upper rear side of the base 1, and a mounting shaft 3 is rotatably arranged on the lifting mechanism 5, and a drill bit 4 is connected to the lower side of the mounting shaft 3, and a driving mechanism 6 is provided on the lifting mechanism 5.

[0028] Lifting mechanism 5 comprises support 51, guide rail 52, sliding seat 53, support frame 54 and electric push rod 55, base 1 top rear side is connected with support 51 symmetrically left and right, support 51 top front side is all connected with guide rail 52, between guide rail 52 The sliding seat 53 is slidably connected between them, the sliding seat 53 is connected wit...

Embodiment 2

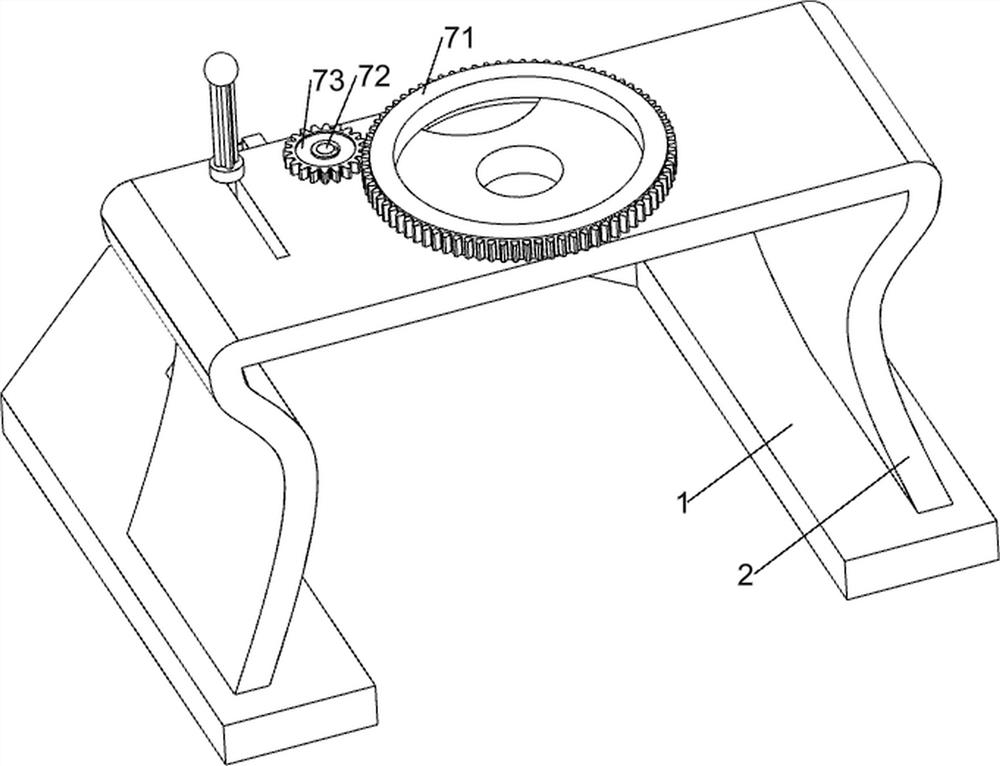

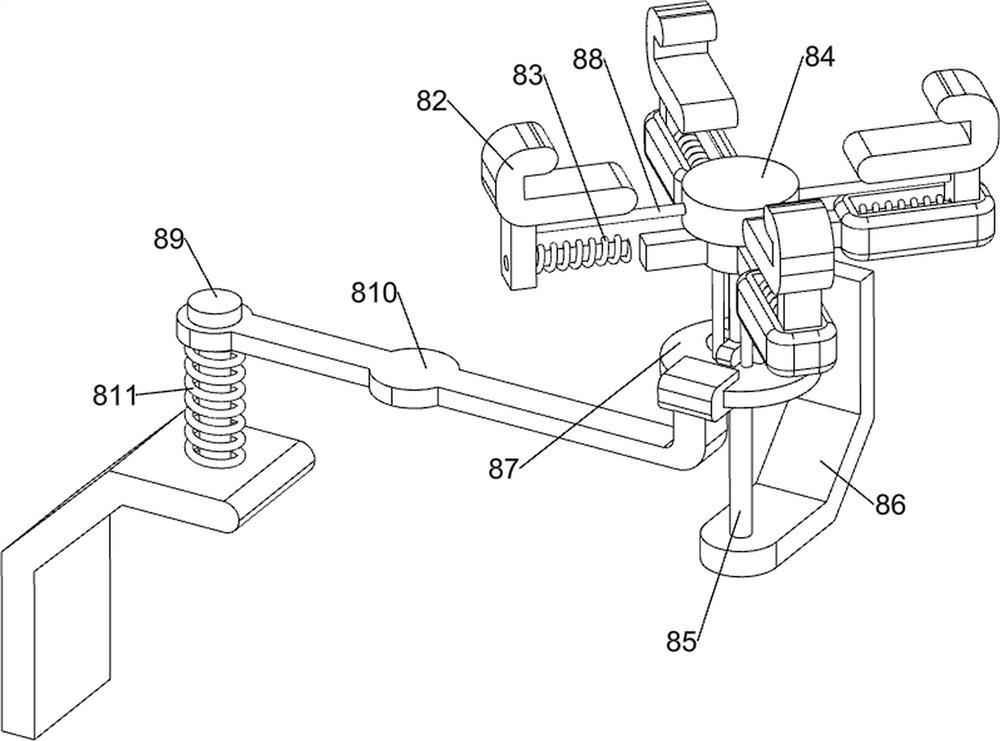

[0032] Such as figure 1 , Figure 3 ~ Figure 8As shown, in some embodiments, a rotating assembly 7 is also included, and the rotating assembly 7 includes a gear ring 71, a rotating shaft 72, a first gear 73, a one-way gear 74, a guide rod 75, a rack 76, a compression spring 77 and The handle 78 is connected to the gear ring 71 in the middle of the top of the workbench 2, and the left rear side of the top of the workbench 2 is connected to the rotating shaft 72. The upper side of the rotating shaft 72 is connected to the first gear 73, and the first gear 73 and the gear ring 71 are mutually connected. meshing, the lower side of the rotating shaft 72 is connected with a one-way gear 74, the upper left side of the workbench 2 is connected with a guide rod 75, and the guide rod 75 is slidably connected with a rack 76, and the rack 76 cooperates with the one-way gear 74, and the rack A compression spring 77 is connected between 76 and the workbench 2, and the compression spring 77...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com