A thick plate ultra-high power laser-deep penetration tig hybrid welding method

A compound welding and deep penetration technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficulty in controlling the shape of the weld surface, poor stability, and welding spatter, so as to reduce the surface oscillation of the molten pool, Effect of reducing shear stress, improving welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

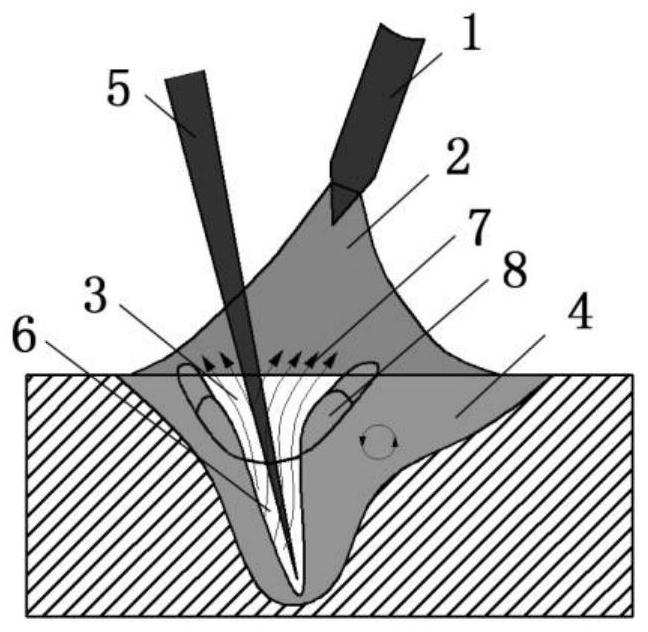

[0034] In this example, a 40mm-thick low-carbon steel plate is used to perform ultra-high-power laser-deep penetration TIG composite welding of the thick plate.

[0035] Using 30KW ultra-high power continuous fiber laser, the laser wavelength is 1070nm, and the laser focusing diameter is 0.69mm.

[0036] Using a rated current of 630A deep penetration TIG welding machine and welding gun.

[0037] S1, grind and clean the surface of the workpiece to be welded, and clamp it on the welding platform with a fixture.

[0038] S2, use the fixture to rigidly fix the ultra-high power laser head and the deep penetration TIG welding torch, the ultra-high power laser and the normal direction of the workpiece surface are inclined 15 degrees, and the deep penetration TIG welding torch and the laser head are inclined 35 degrees.

[0039] S3, set the welding parameters, specifically: the laser power is 20KW, the defocus amount is -10mm, the diameter of the deep penetration TIG tungsten electrode...

Embodiment 2

[0042] The difference between this example and Example 1 is that the laser output power during welding is 30KW, and the rest of the parameter settings and operation process are the same as those of Example 1. The obtained weld is as follows Figure 5 shown in (c).

Embodiment 3

[0044] In this example, a 40mm-thick low-carbon steel plate is used for ultra-high-power single-laser welding of the thick plate.

[0045] Using 30KW ultra-high power continuous fiber laser, the laser wavelength is 1070nm, and the laser focusing diameter is 0.69mm.

[0046] S1, grind and clean the surface of the workpiece to be welded, and then clamp it on the welding platform with a fixture.

[0047] S2, the ultra-high-power laser head is rigidly fixed by a fixture, and the ultra-high-power laser is inclined 15 degrees to the normal direction of the workpiece surface.

[0048] S3, set the welding parameters, specifically: the laser power is 20KW, and the defocus amount is -10mm. The welding speed is 1.2m / min. The protective gas is 99.999% high-purity argon, and the gas flow is 20L / min.

[0049] S4, pre-pass the shielding gas, start the laser incident, and move the laser head relative to the workpiece to be welded, perform ultra-high-power single-laser welding, and obtain w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com