Surface grinding and polishing device for building materials

A technology for polishing devices and building materials, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding drive devices, etc. It can solve problems such as difficult removal, large dust, and large supporting environmental protection equipment that are not suitable for operation. To achieve the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

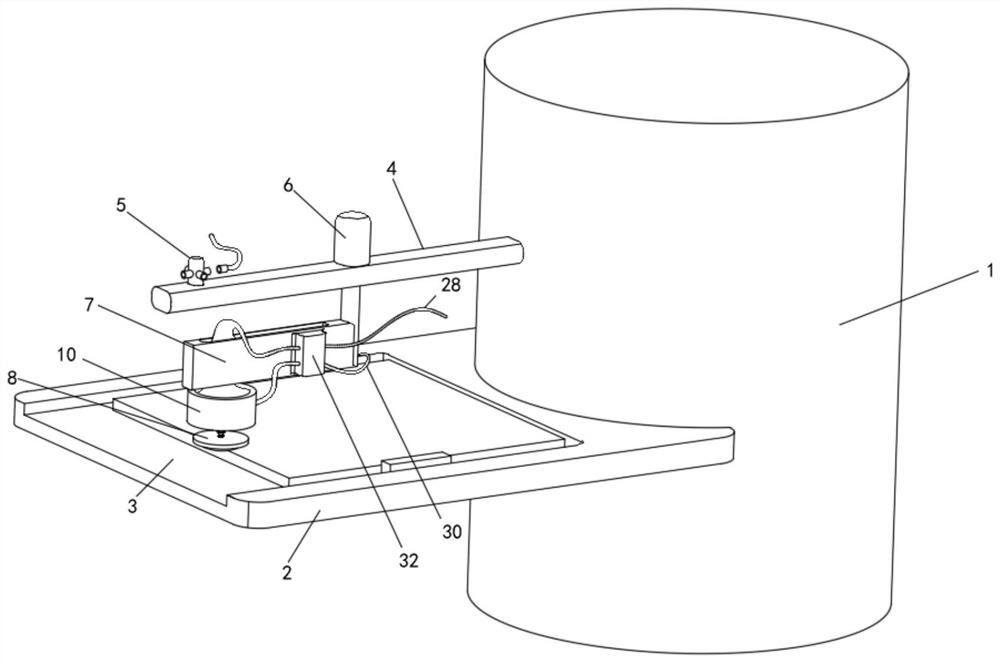

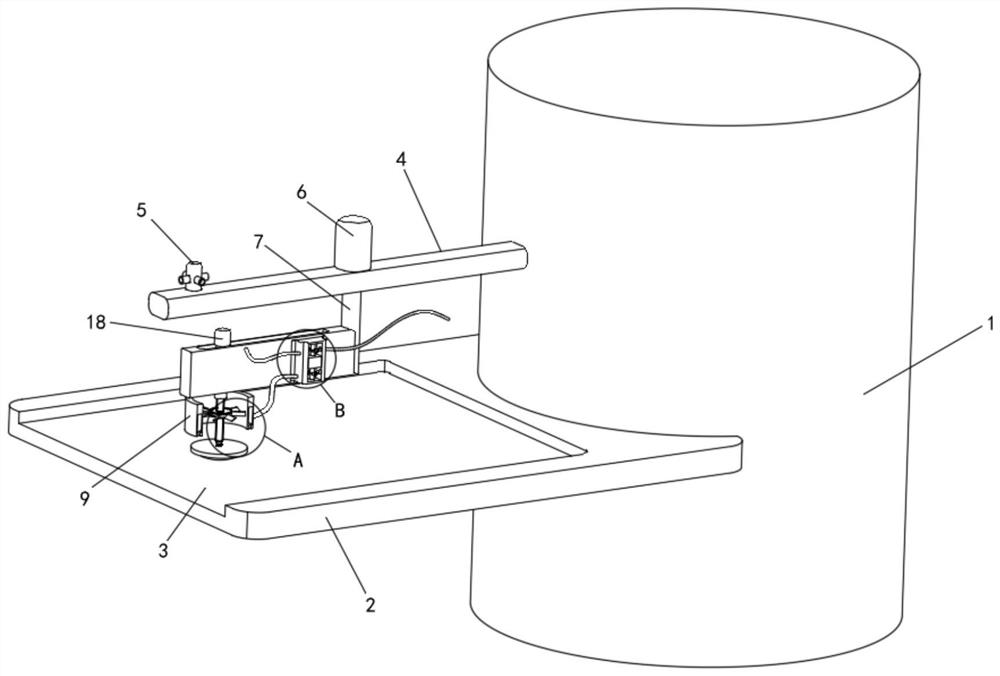

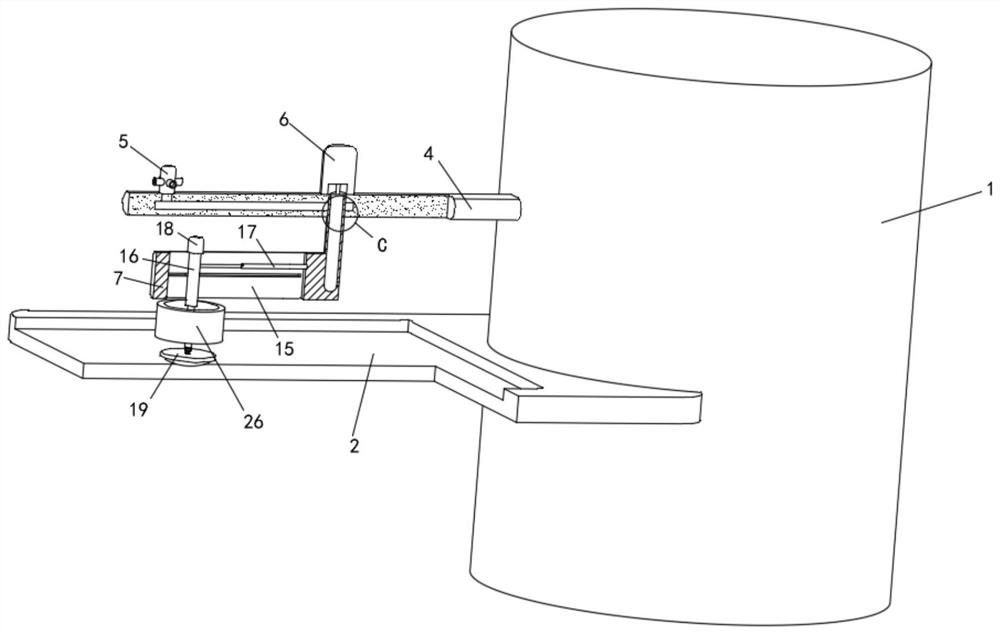

[0034] Such as Figure 1-3 As shown, a surface grinding and polishing device for building materials includes a body 1 and a table plate 2. The body 1 acts as a stable base for a foundation, and it has a certain quality for overall stability. At the same time, due to the front end The role of the body is vibration, so the body 1 also plays a role in reducing the vibration amplitude, so the volume of the body 1 should be designed to increase its own quality, and it can be combined with a passive anti-seismic device structure for better stability. , the body 1 in this embodiment is cylindrical, and the table 2 is fixed on one end surface of the body 1, and is normally located at the lower part of the middle to enhance stability. The table 2 is set horizontally for placing materials that need to be polished. There is a processing slot 3 on the disc 2 for placing materials. There is a gap at the end of the processing slot 3 away from the table disc 2. The polished and polished mate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap