Household kitchen garbage dewatering and briquetting equipment

A technology for kitchen waste and block equipment, which is applied in presses, solid waste removal, chemical instruments and methods, etc., can solve the problems of low treatment efficiency, time-consuming, and slow dehydration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

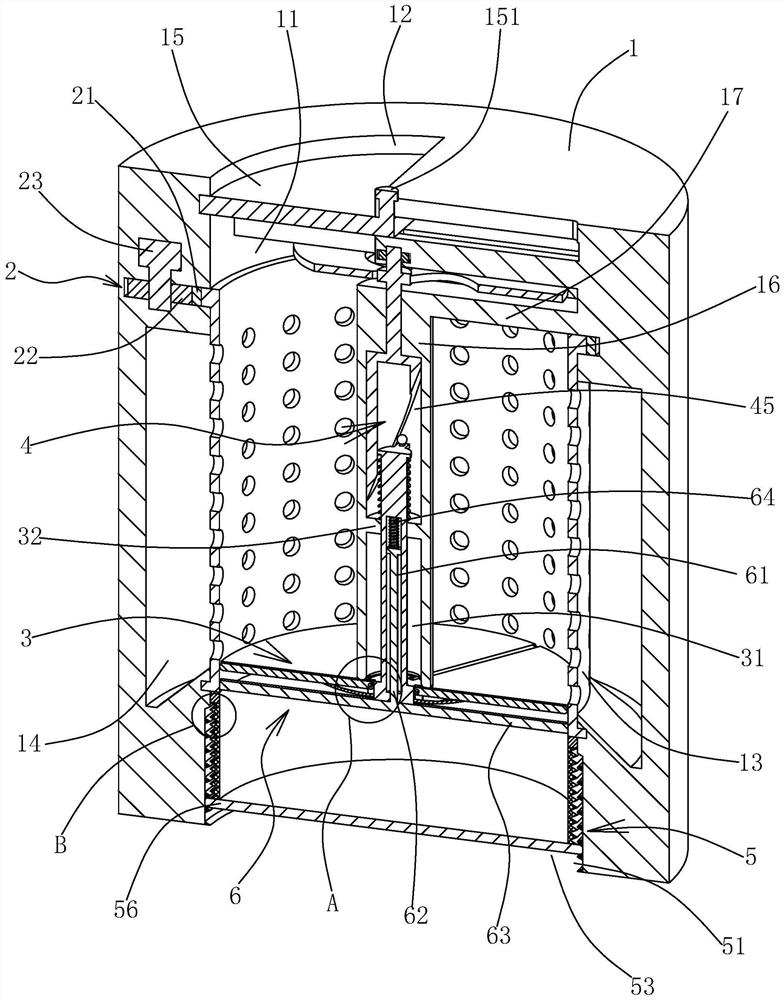

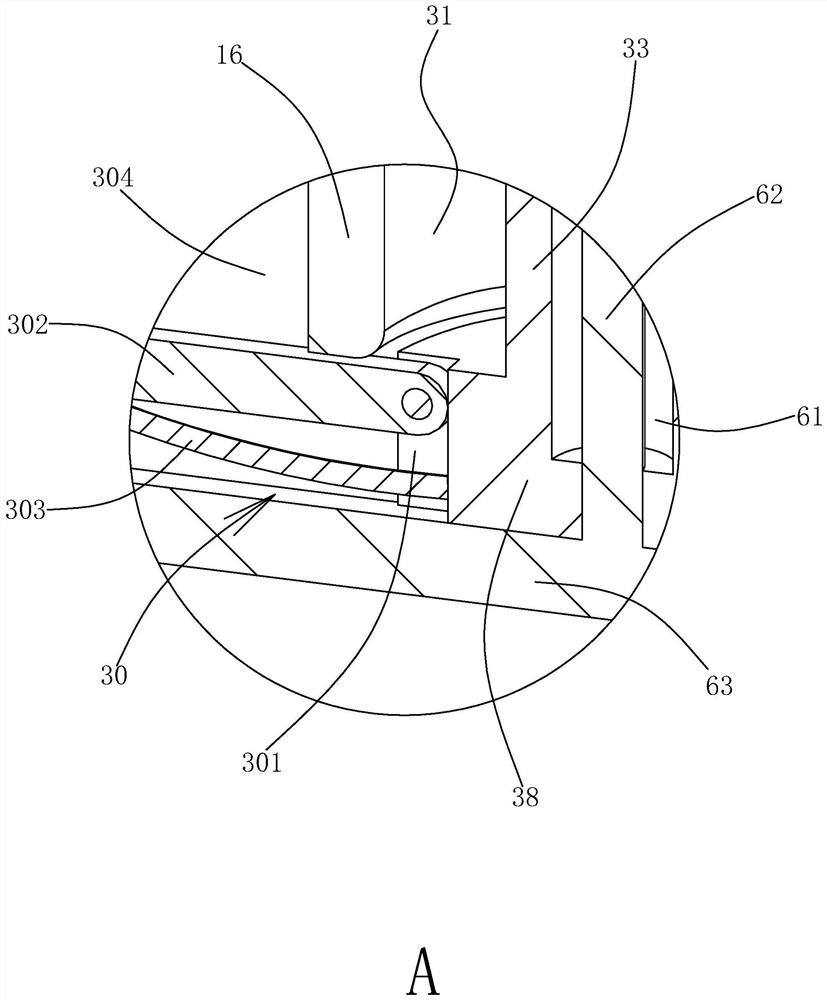

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

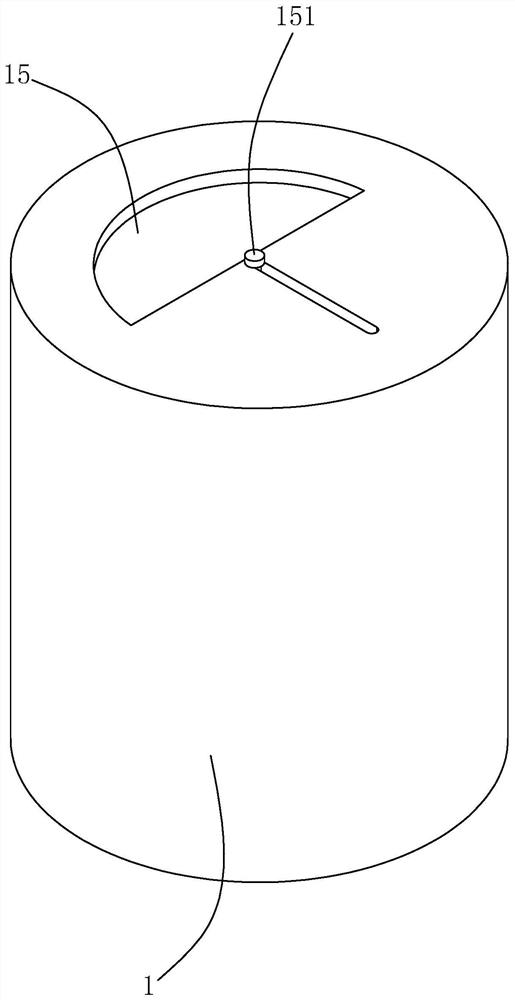

[0027] A household kitchen waste dehydration briquetting equipment, such as figure 1 , figure 2 As shown, it includes a body 1 provided with a dehydration chamber 11. The upper end of the dehydration chamber 11 is provided with a feeding port 12 communicating with the outside world. 13. A drainage bin 14 is arranged on the periphery of the dehydration ring cylinder 13; a shroud 15 is installed for sliding at the upper end of the feeding port 12, and a shroud 15 is arranged at the lower end of the shroud 15 to convert the power generated by its sliding into driving the telescopic disk device 3 to slide up and down so that The telescopic disc device 3 is used as a pressing plate or partition when it is opened, and the transmission device 4 that drives the foreign matter to fall when retracted. The lower end of the dehydration chamber 11 is provided with an el...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap