Gas film rigidity measuring method of gas bearing

A technology of gas bearing and gas film stiffness, which is applied in the direction of measuring devices, elastic testing, mechanical parts testing, etc., and can solve the problems of large measurement error and low precision of gas film stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

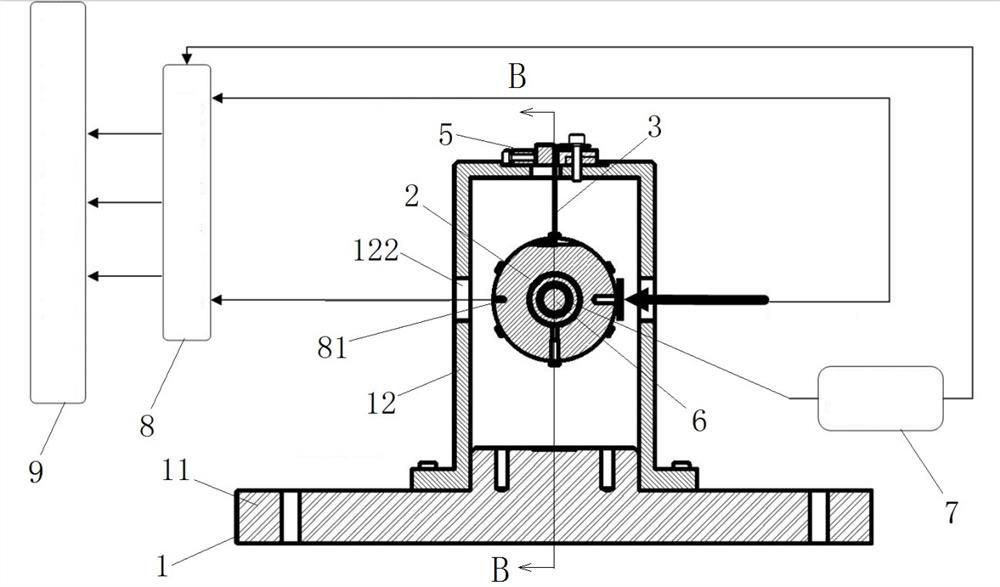

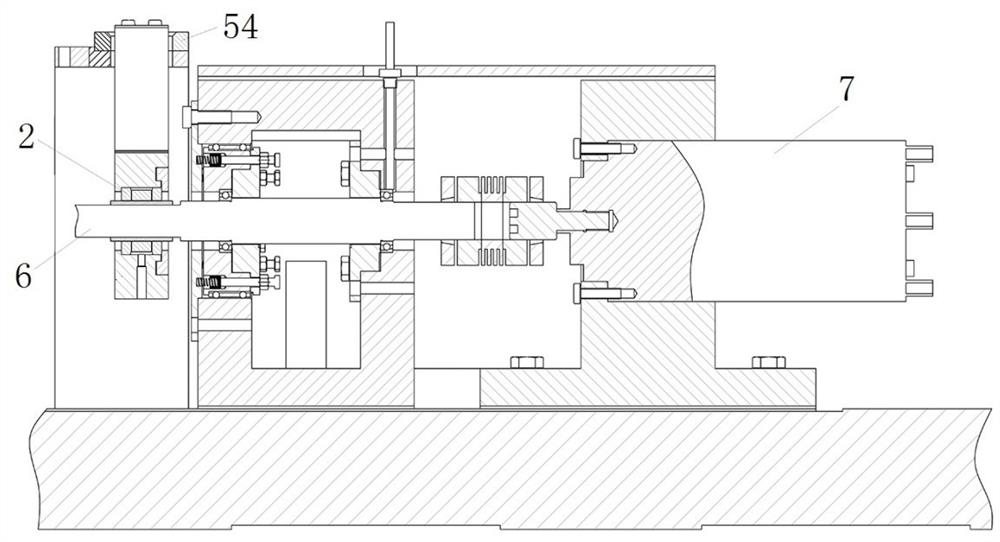

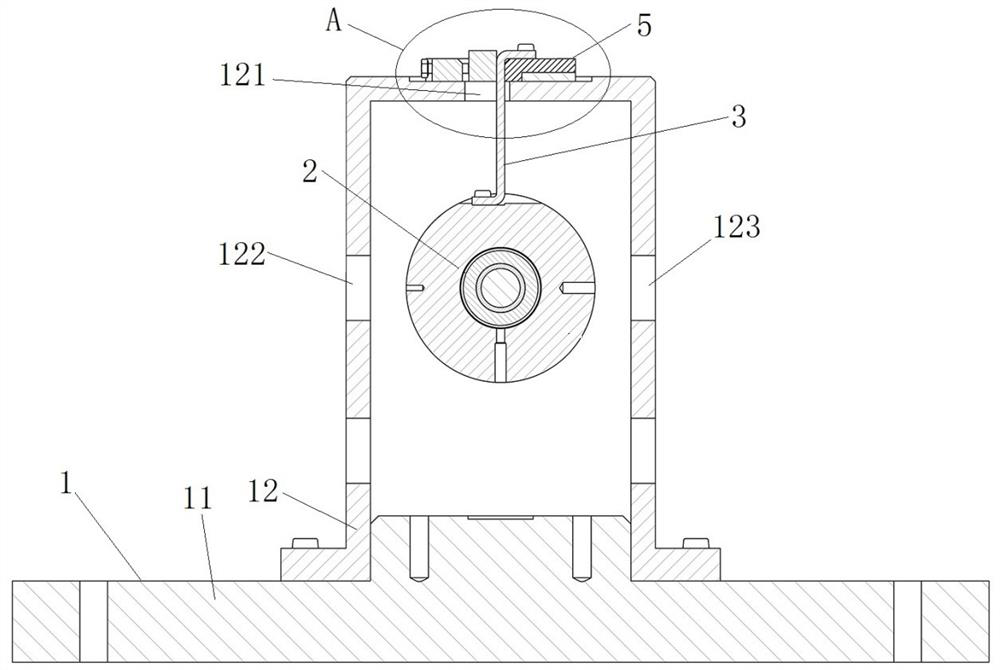

[0040] The gas film stiffness measuring method of the gas bearing of the present invention mainly comprises the following steps:

[0041] (1) Set the gas bearing to be tested on the shaft system, maintain the relative position of the gas bearing and the shaft system through the holder, and make the gas bearing to be tested and the shaft system have an eccentric distance;

[0042] (2) Under the condition of no gas lubrication, apply external excitation to the gas bearing to be tested, and calculate the non-lubricating stiffness k of the gas bearing according to the vibration of the gas bearing B ;

[0043] (3) In the state of lubricating gas in the gas bearing cavity, drive the shafting to rotate, apply the external excitation to the gas bearing to be tested, and process and calculate the composite stiffness of the gas bearing when there is gas lubrication according to the vibration of the gas bearing k BQ ;

[0044] (4) according to k BQ =k Q +k B Calculate, calculate the ...

specific Embodiment 2

[0066] The difference between it and the specific embodiment 1 is: in the process of hoisting and fixing the gas bearing to be tested on the support frame, the clamping line between the center of the gas bearing to be tested and the center of the shafting and the vertical plane The angle is less than 90°. In the state of lubricating gas and non-lubricating gas, the direction of the external excitation applied to the gas bearing to be tested passes through the center of the gas bearing to be tested, and the external excitation point on the gas bearing to be tested, the center of the gas bearing to be tested and the center of the shafting are in common line arrangement to measure the gas film stiffness of the gas bearing to be tested in the direction of the extension of the line between the center of the gas bearing to be tested and the center of the shafting.

specific Embodiment 3

[0068] The difference between it and the specific embodiment 1 is: in the process of hoisting and fixing the gas bearing to be tested on the support frame, the angle between the line between the center of the gas bearing to be tested and the center of the shafting and the vertical plane is made less than 90°. In the state of lubricating gas and non-lubricating gas, an external excitation in the horizontal direction is applied to the gas bearing to be tested, so as to measure the gas film stiffness of the gas bearing to be tested in the horizontal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com