Power equipment cabinet

A technology for power equipment and cabinets, applied in the field of power distribution equipment, can solve the problems of potential safety hazards and poor dust removal effects in manual dust removal, and achieve the effects of enhancing wind power and enhancing dust removal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

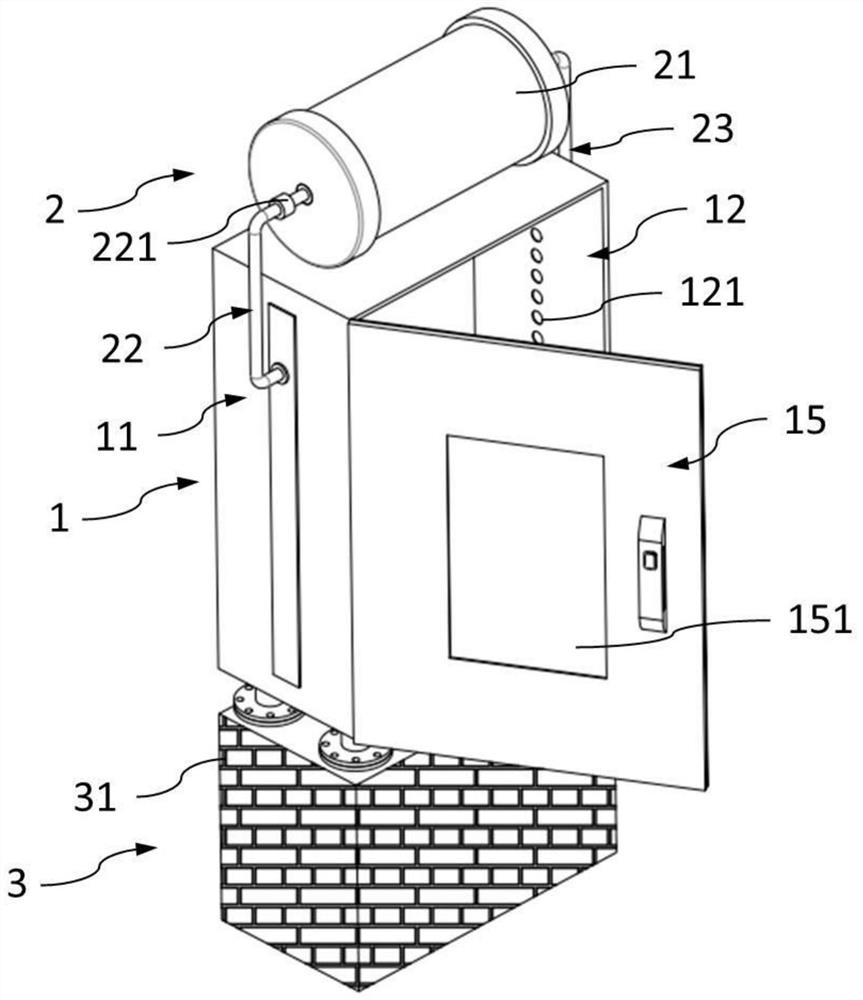

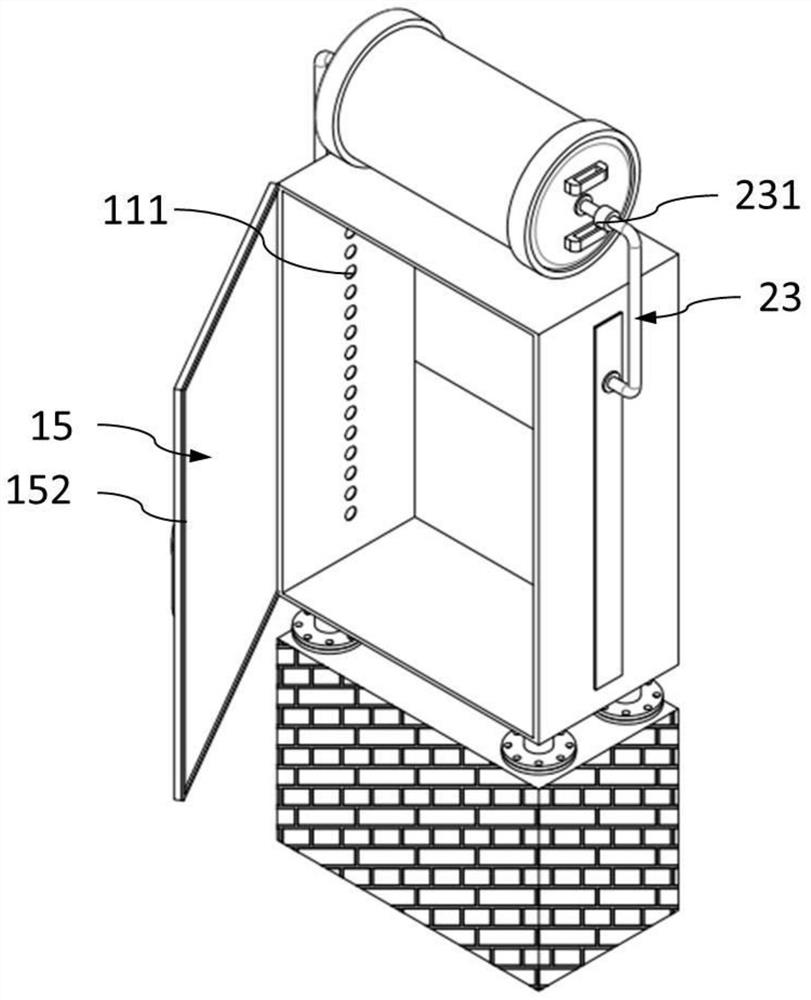

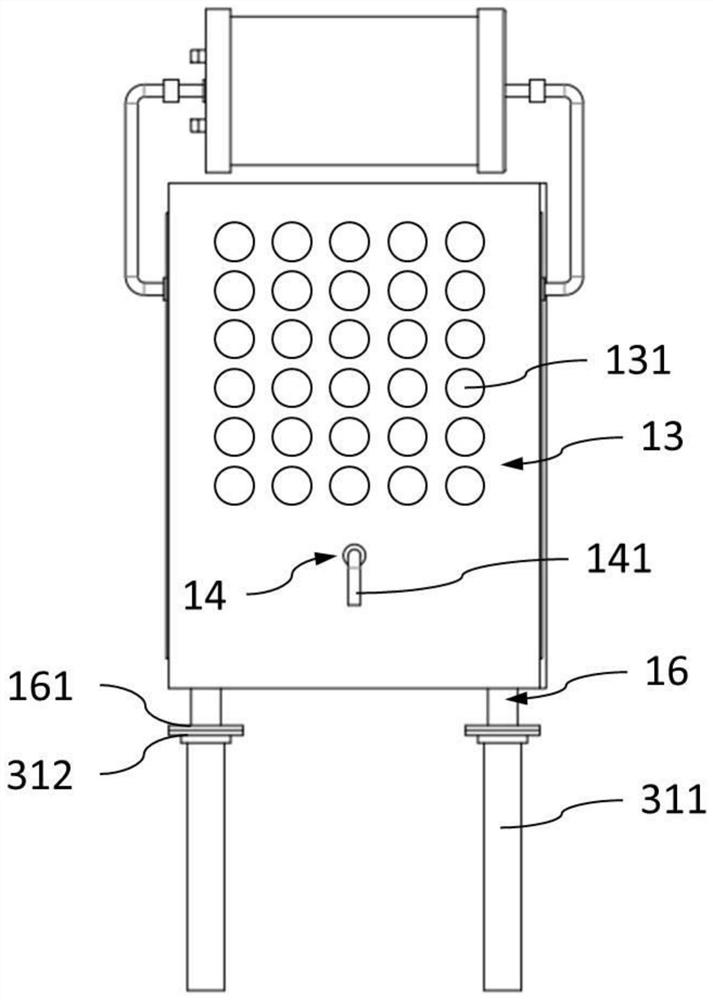

[0030] figure 1 It is the first axonometric view of the power equipment cabinet provided by Embodiment 1 of the present invention, figure 2 It is the second isometric view of the power equipment cabinet provided by Embodiment 1 of the present invention, as shown in Figure 1-2 As shown, this embodiment provides a power equipment cabinet, which includes: a cabinet body 1 and a dust removal mechanism 2 . The dust removal mechanism 2 can quickly and efficiently remove dust from the cabinet body 1 . Specifically, the overall structural outline of the cabinet body 1 is a cuboid or similar cuboid, including a top board, a bottom board, a front board, a rear board, a left board and a right board. In this embodiment, the cabinet body 1 includes a first air blast side plate 11 , a second air blast side plate 12 and an exhaust back plate 13 , and the first air blast side plate 11 and the second air blast side plate 12 are arranged opposite to each other. Preferably, the first air bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com