A method for purifying nonapeptide-1

A surface activation and modification technology, applied in the field of peptide purification, can solve the problems of low purity of nonapeptide-1, reduced production cost, only 79%, etc., to reduce the steric hindrance effect, prolong the service life, and not destroy the activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a modified silica gel chromatography filler, which is prepared by the following method:

[0058] 1) 1 g of silica gel microspheres was added to 20 mL of a mixed solution containing 8 wt% hydrochloric acid and 0.6 wt% methanesulfonic acid, stirred at 40 °C for 2 h, filtered with suction, washed with water until neutral, and dried under vacuum at 90 °C. to obtain surface-activated silica microspheres;

[0059] 2) 2 g vinyltriethoxysilane was mixed with 4.5 g 2-aminophenol-4-sulfonanilide, and the reaction was stirred at 30 °C for 2 h, and distilled under reduced pressure to obtain 2-aminophenol-4-sulfonanilide Modified silane coupling agent; under nitrogen protection, 1 g of surface-activated silica gel microspheres and 2.6 g of 2-aminophenol-4-sulfonanilide modified silane coupling agent were added to 30 g of toluene, and the reaction was stirred at 80 °C 4 h, filter after the reaction, the filter residue is washed with toluene, acetone, ...

Embodiment 2

[0063] This example provides another modified silica gel chromatography filler, the preparation method of which is basically the same as that in Example 1, the difference is that in step 1), vinyltriethoxysilane, 2-aminophenol-4-sulfonic acid The amount of anilide added was 2 g and 1 g, respectively.

Embodiment 3

[0065] This example provides another modified silica gel chromatography filler, the preparation method of which is basically the same as that in Example 1, the difference is that in step 1), vinyltriethoxysilane, 2-aminophenol-4-sulfonic acid The addition amount of the anilide was 2 g and 2 g, respectively.

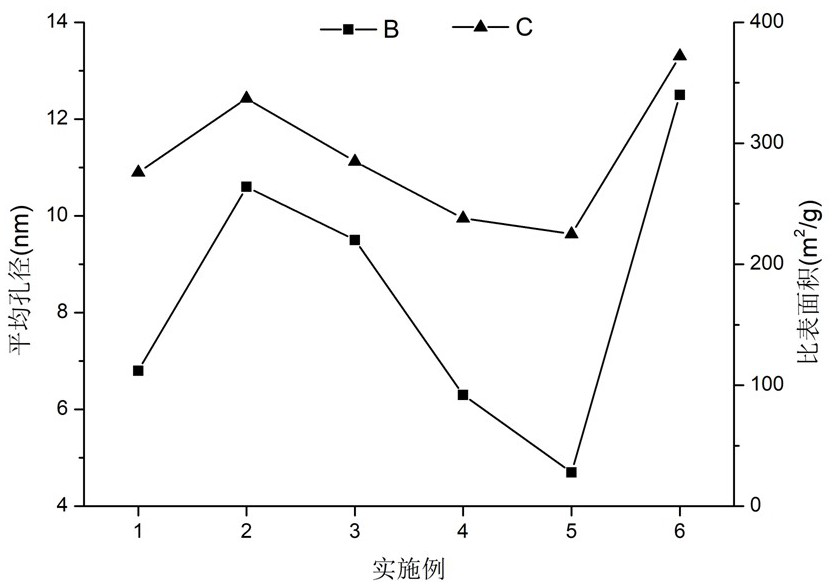

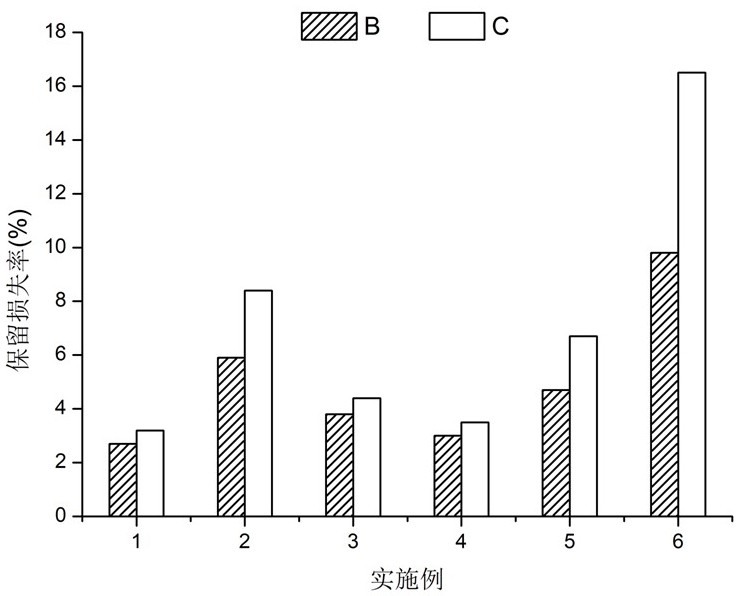

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com