Multi-stage inertial micro-fluidic blood sample processing chip integrating micro-mixer and Tesla valve

A micro-mixer and processing chip technology, which is applied in the direction of mixers, laboratory appliances, and laboratory containers, can solve the problems of low sample throughput, low processing efficiency, and low precision, and achieve the effect of high screening purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

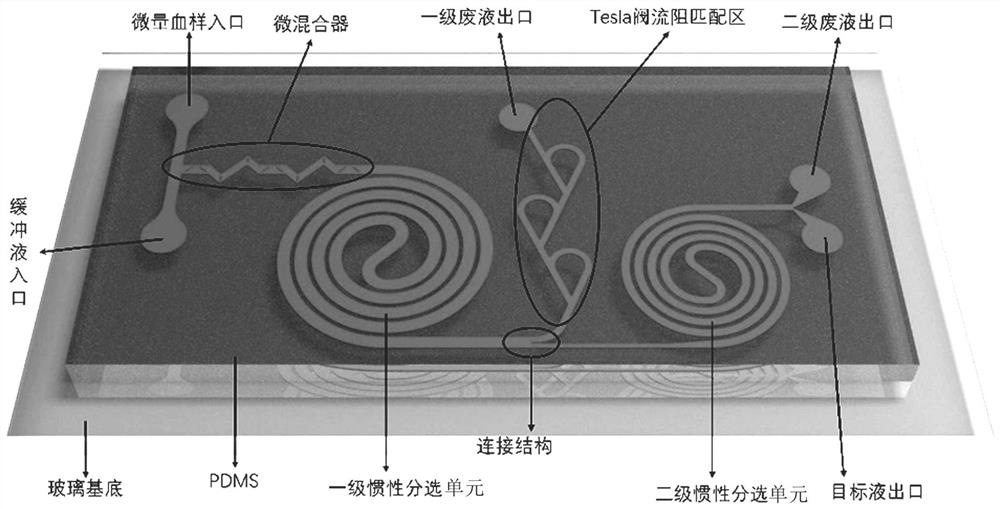

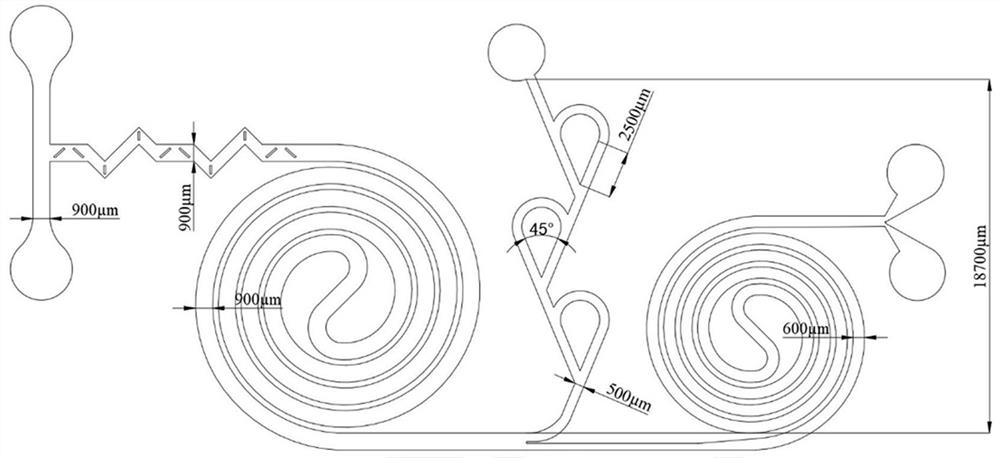

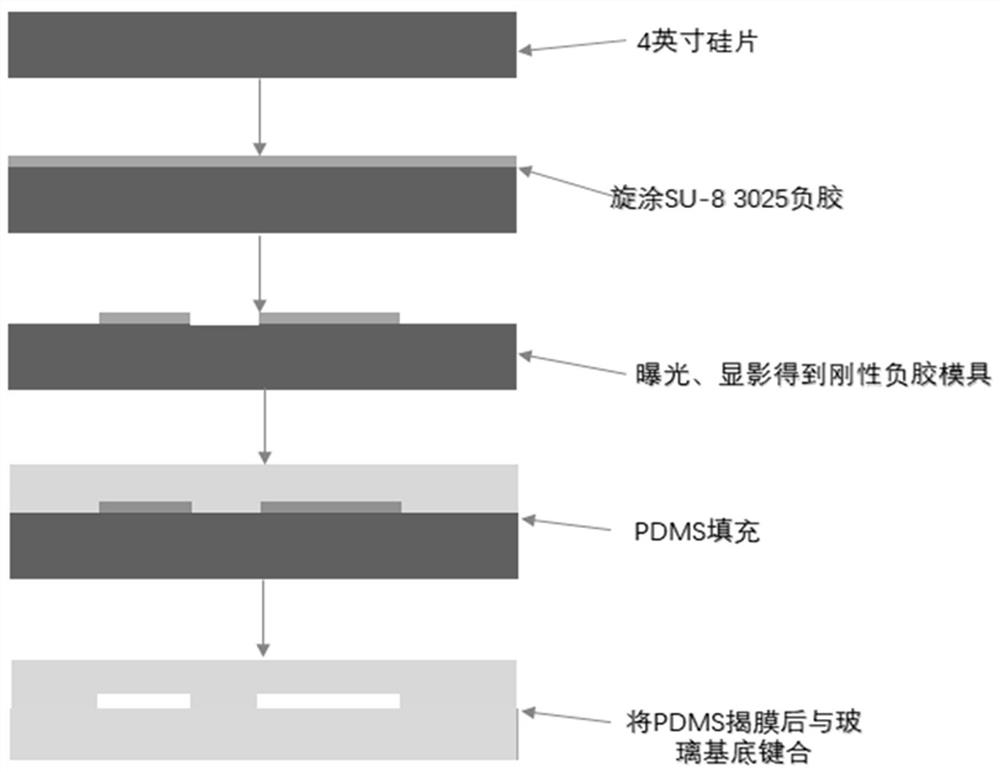

[0023] Such as figure 1 , 2 As shown, a multi-stage inertial microfluidic blood sample processing chip integrating a micro-mixer and a Tesla valve, the chip is prepared with an inlet area, a micro-mixer, a first-stage inertial sorting unit, a Tesla valve flow resistance matching area, A secondary inertial sorting unit and an outlet area; the inlet area is composed of a trace blood sample inlet and a buffer inlet and an intermediate section connecting the trace blood sample inlet and the buffer inlet, and the intermediate section is connected to a micro-mixer; the micro-mixer It consists of a plurality of sequentially connected micro-mixing units and final channels, each micro-mixing unit consists of a first channel, a second channel connected to the first channel at an obtuse angle, a third channel connected to the second channel at a right angle, and It is composed of a fourth channel at right angles to the third channel, and the second channel and the fourth channel are lo...

Embodiment 2

[0026] The flow resistance matching area of the Tesla valve is formed by connecting three T45C Tesla valves in sequence; the length of the flow resistance matching area of the Tesla valve is 18700 μm, which is the distance from the bifurcation of the connection structure to the front end of the first-stage waste liquid outlet. distance, or the distance between the first and last ends of the three Tesla valves, such as figure 2 shown. The T45C valve consists of a main flow channel, the first and second flow channels bifurcated from the main flow channel, and an arc-shaped flow channel connected between the other ends of the first and second flow channels; the first flow channel is along the The direction of the main flow channel extends; the angle formed between the first and second flow channels is 45 degrees; the length of the first flow channel is 2500 μm; the width of each flow channel is 500 μm. With the Tesla valves of the above models and sizes and the above combin...

Embodiment 3

[0028]Both the first-level inertial sorting unit and the second-level inertial sorting unit adopt passive inertial microfluidic cell sorters, which have a double-helical channel structure, and the channel width of the first-level inertial sorting unit is 900 μm. The channel width of the secondary inertial sorting unit is 600 μm. The passive inertial microfluidic cell sorter is the prior art, but the present invention chooses the passive inertial microfluidic cell sorter with the above size, which can exert its maximum inertial focusing effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com