Aaluminum alloy hub demolding detection system

A technology of aluminum alloy wheels and detection systems, applied in metal processing equipment, safety devices, manufacturing tools, etc., can solve the problems of core sticking to the mold, high manufacturing cost, and only 50% to 60% yield, and achieve convenient shrinkage The effect of demoulding and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

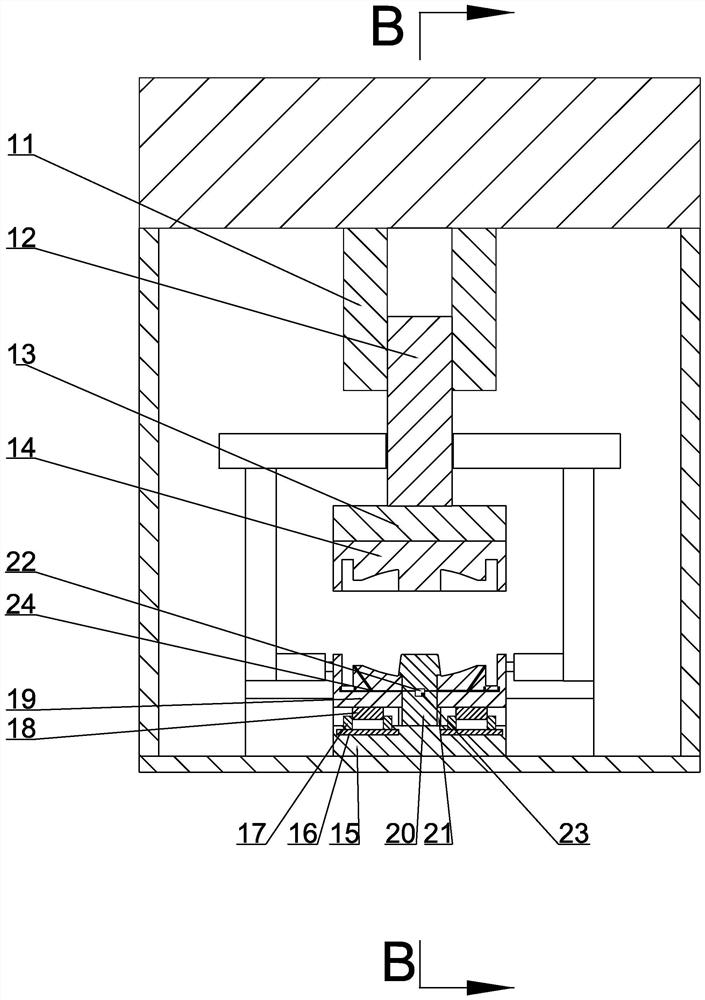

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

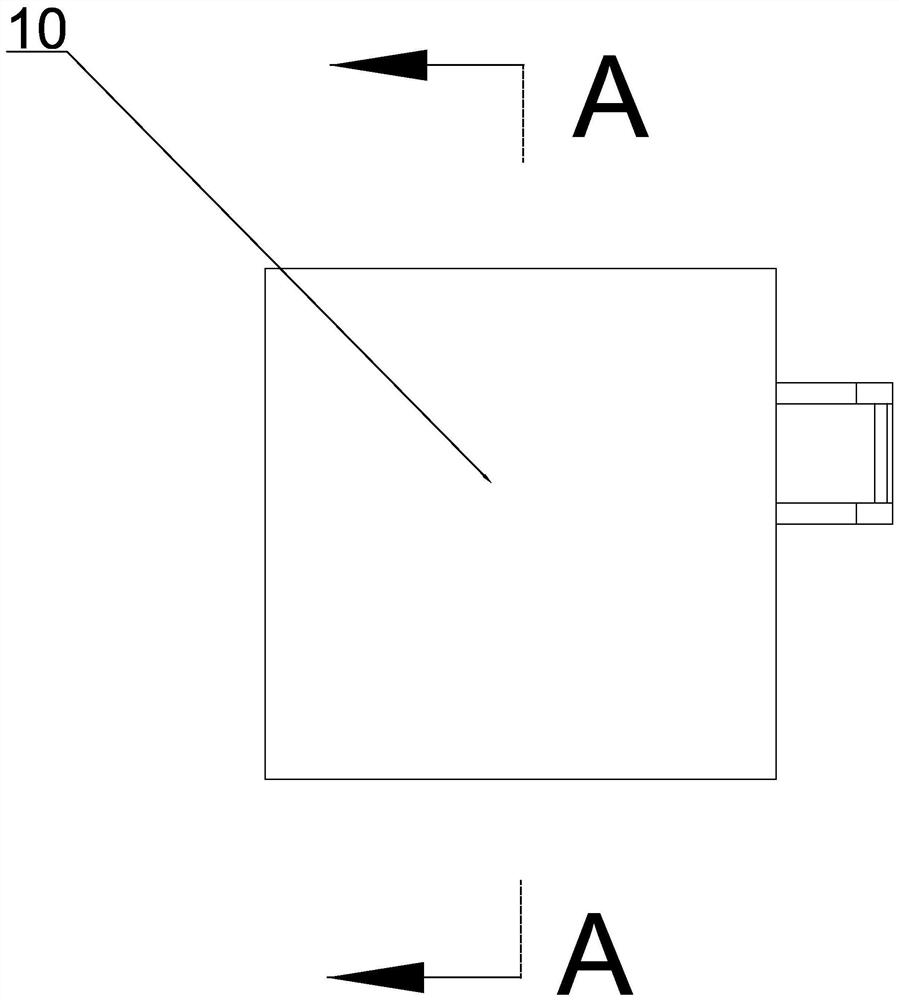

[0028] Such as Figure 1-Figure 11 As shown, a demoulding detection system for an aluminum alloy wheel includes a box body 10, a hydraulic housing 11 is fixed on the inner upper surface of the box body 10 away from the lower surface, and a hydraulic rod 12 is slid inside the hydraulic housing 11. The hydraulic rod 12 A mounting block 13 is fixed at the output end of the mounting block 13, and an upper mold 14 is fixed on the mounting block 13 away from the hydraulic rod 12. A mounting base 15 is fixed on one side of the inner bottom of the box body 10, and a telescopic bracket is fixed on both sides of the upper surface of the mounting base 15. Base 16, the middle part of the upper surface of the mounting base 15 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com