Secondary slide core-pulling mechanism of injection mold

A technology for injection molds and core-pulling mechanisms, which is applied in the field of secondary row-position core-pulling mechanisms, can solve problems such as easy failure, mold core damage, and potential safety hazards, and achieve the effect of small limitations and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

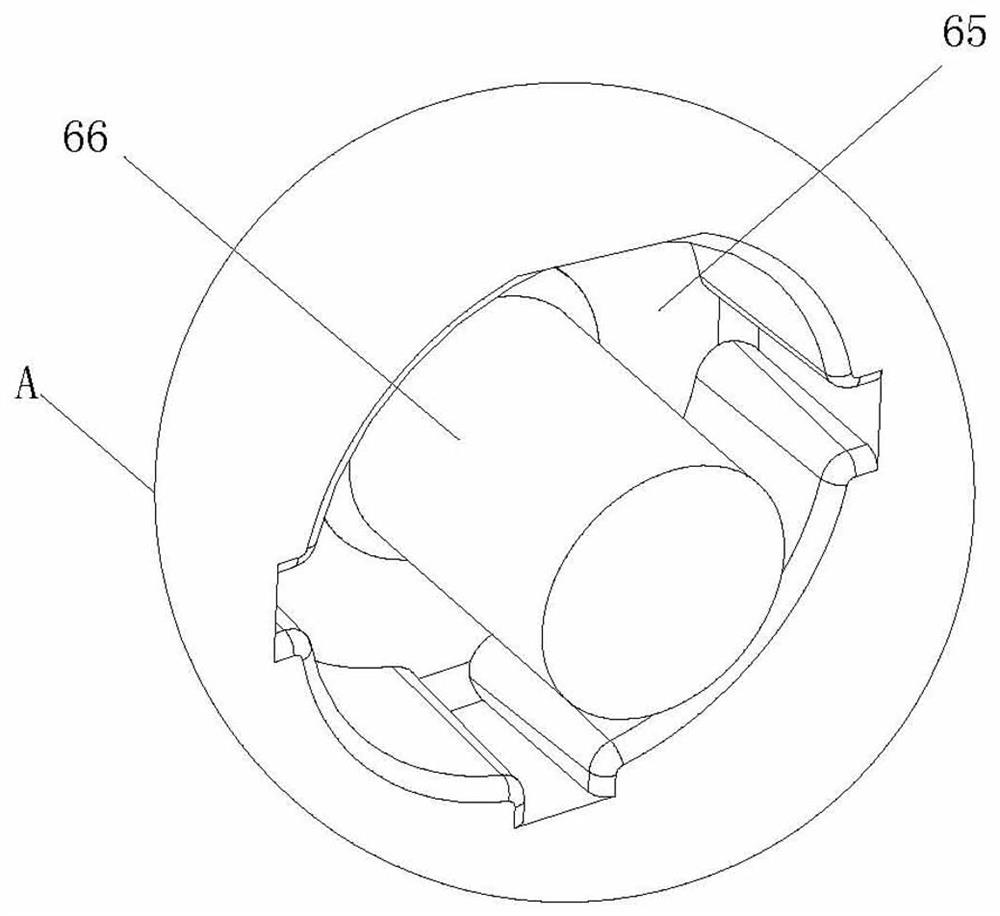

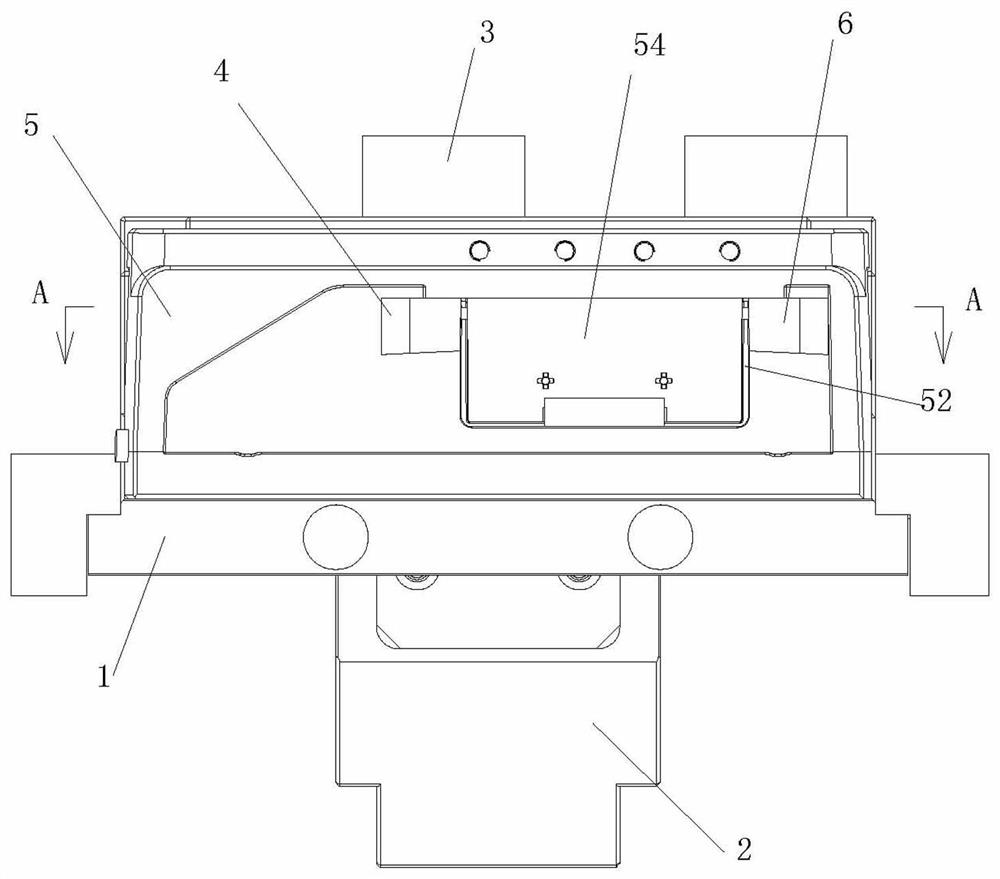

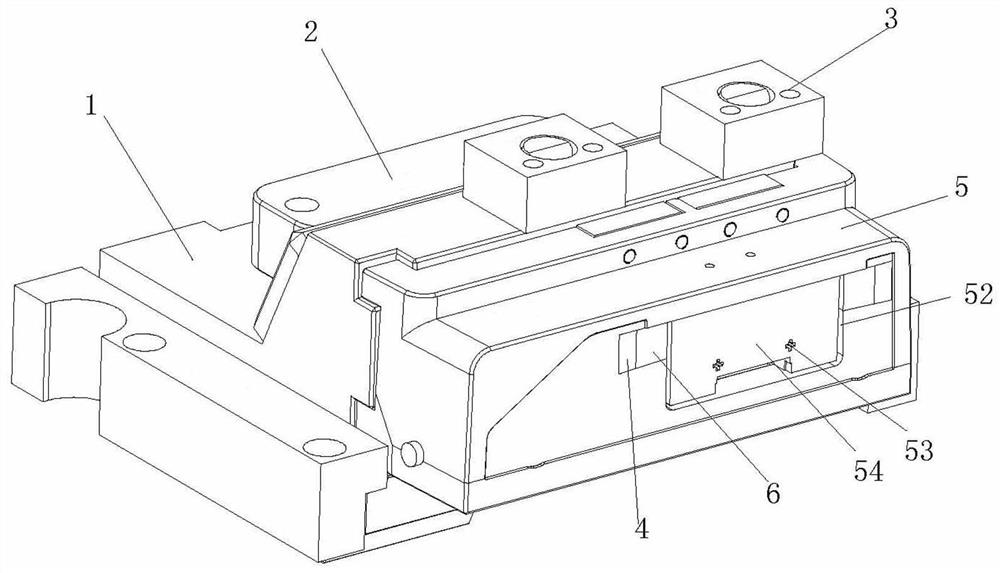

[0032] Embodiment one, such as Figure 1 to Figure 13 As shown, an injection mold for the battery box cover of a car refrigerator includes an injection upper mold 10, an injection lower mold 20, and a secondary row core-pulling mechanism, and the secondary row core-pulling mechanism includes a sliding device arranged under the injection molding The large row slide block 1 on the mold 20 and the delayed large shovel base 2 and two small shovel bases 3 installed on the injection molding upper mold 10, the position of the large row slide block 1 corresponding to the delayed large shovel base 2 is provided with The driven hole 11, the two small shovel bases 3 are provided with a diagonal support pin 31, and the large row slider 1 is provided with two small row sliders 4, two inner inserts 6 and outer inserts. Part 5, the position corresponding to the slanting support pin 31 on the small row position slider 4 is provided with a driven oblique hole 41, the outer insert 5 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com