Double-motor electric drive axle structure

A technology of electric drive and dual motors, which is applied in the direction of electric power devices, power devices, control devices, etc., can solve problems such as power interruption, bad road conditions, hidden dangers of accidents, etc., and achieve the effect of compact structure and saving layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

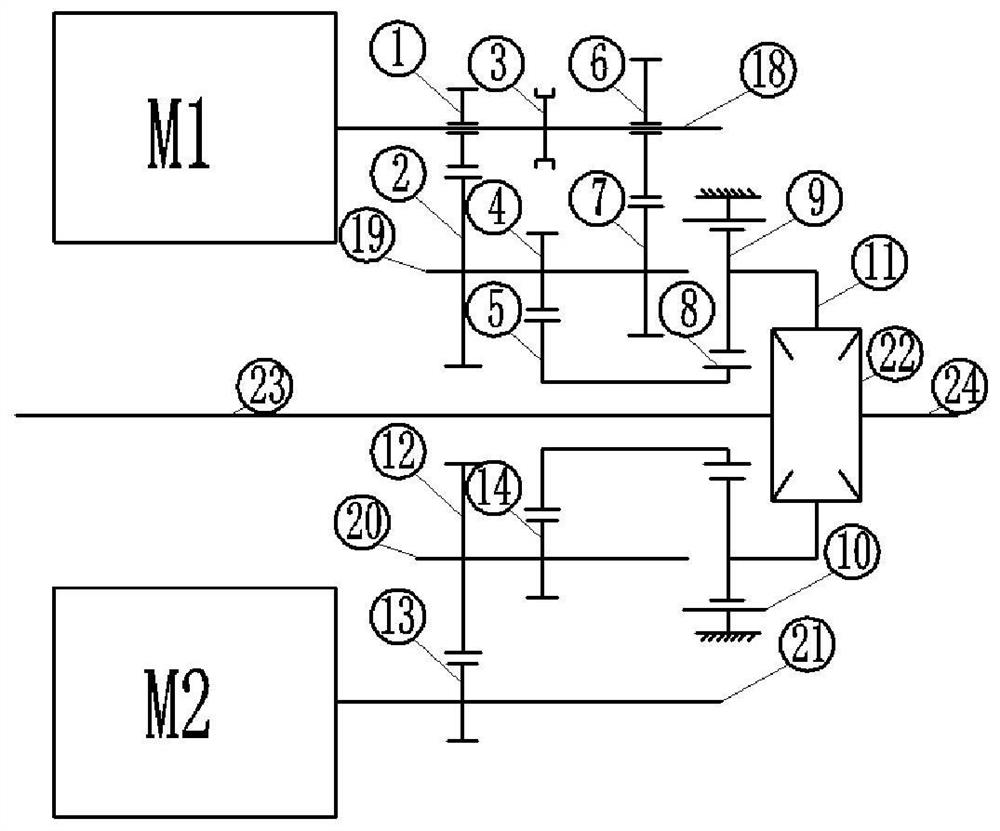

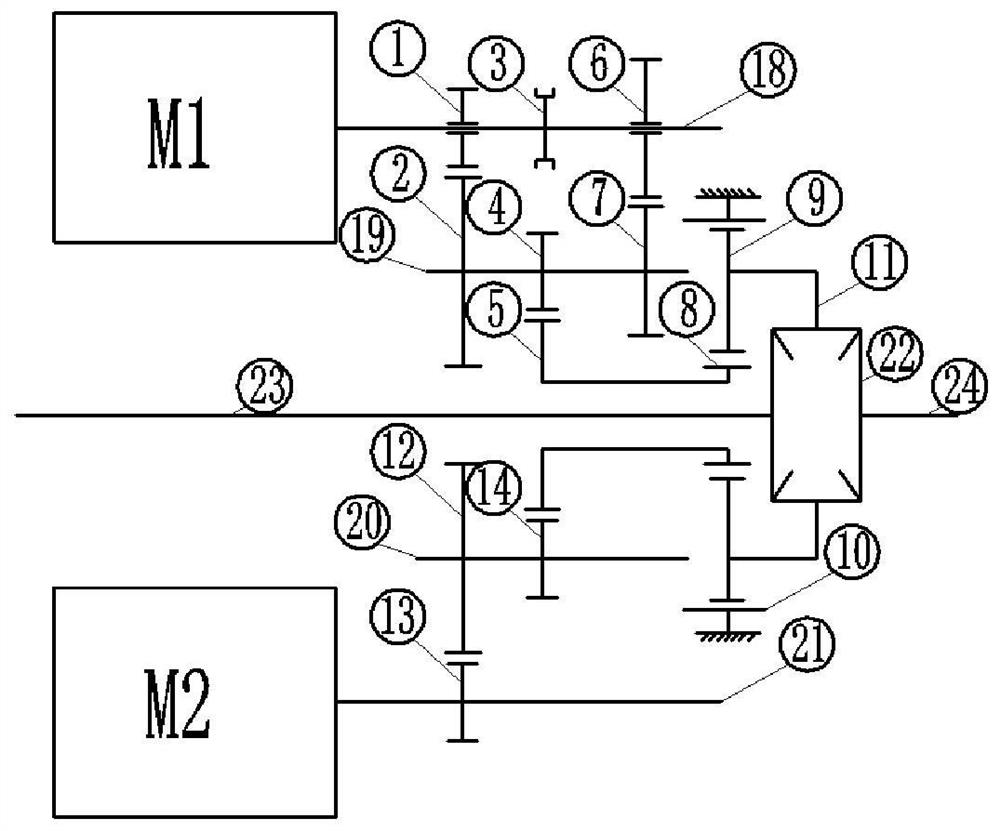

[0033] According to a preferred embodiment of the present invention, see figure 1 , providing a dual-motor electric drive axle structure, characterized in that it includes:

[0034] The first input shaft 18 is connected to the first motor M1;

[0035] The first gear 1 and the second gear 6 are relatively rotatably sleeved on the first input shaft 18;

[0036] The sliding sleeve 3 is slidably connected to the first input shaft in a manner of synchronous rotation with the first input shaft and can move and switch between the first position, the middle position and the second position. The sliding sleeve 3 When positioned at the first position, the first gear 1 and the first input shaft 18 are locked to transmit the power of the first motor to the first gear through the first input shaft, and when the sliding sleeve 3 is positioned at the second position, the second gear is locked 6 and the first input shaft 18 to transmit the power of the first motor to the second gear via the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com