Intelligent material management equipment for scribing blades

A technology for intelligent material and equipment management, applied in the field of warehousing, it can solve the problems of low material feeding efficiency, scrap wafers, waste of reclaiming time, etc., and achieve the effect of reducing floor space, small floor space, and avoiding work mistakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

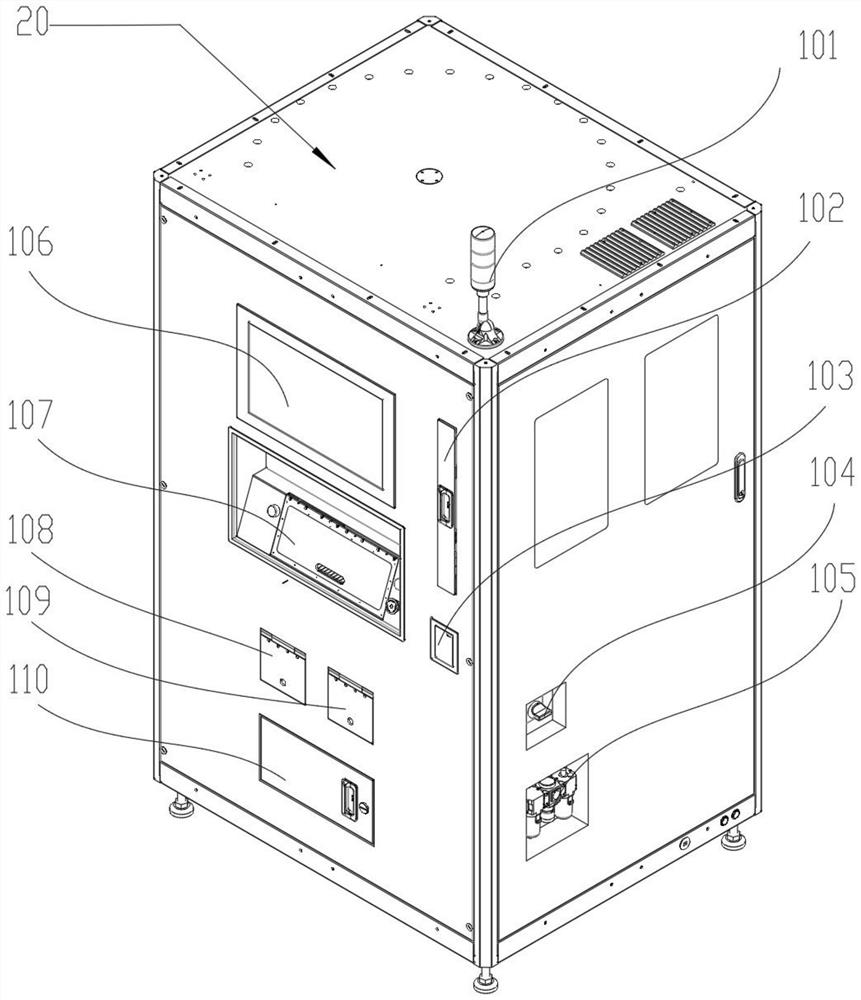

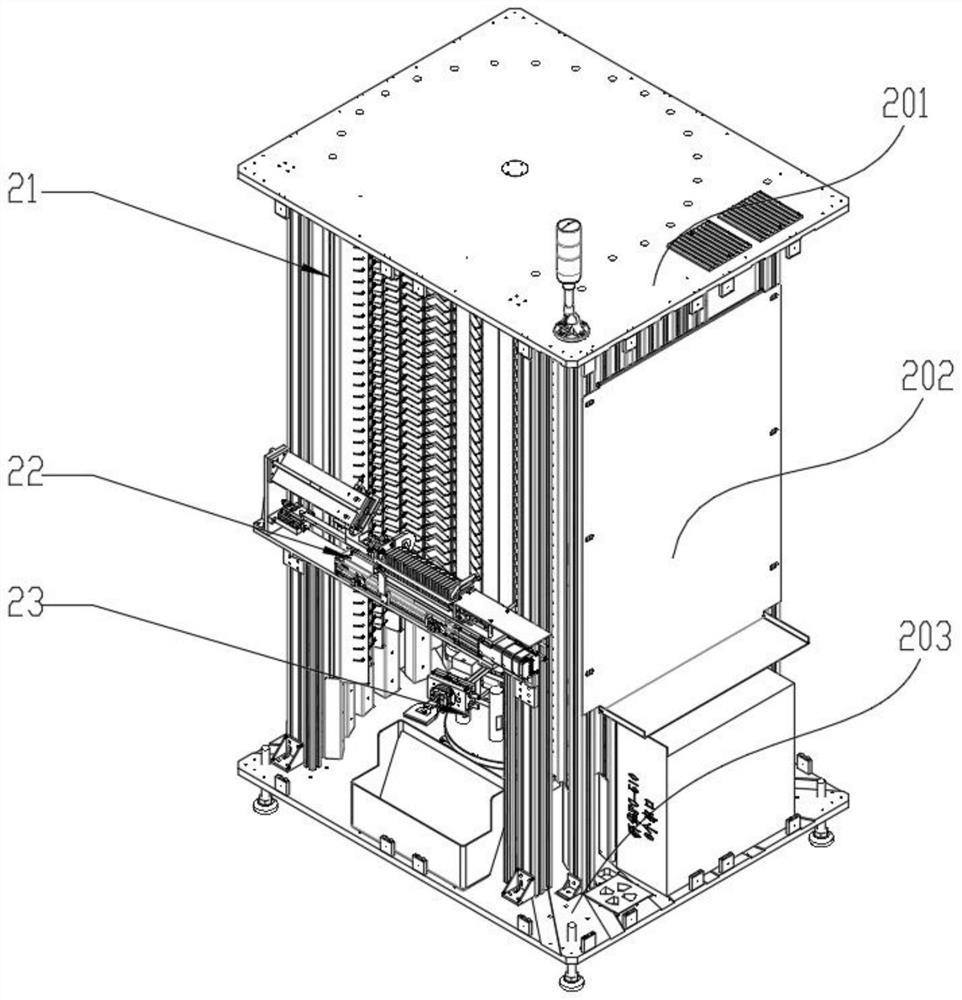

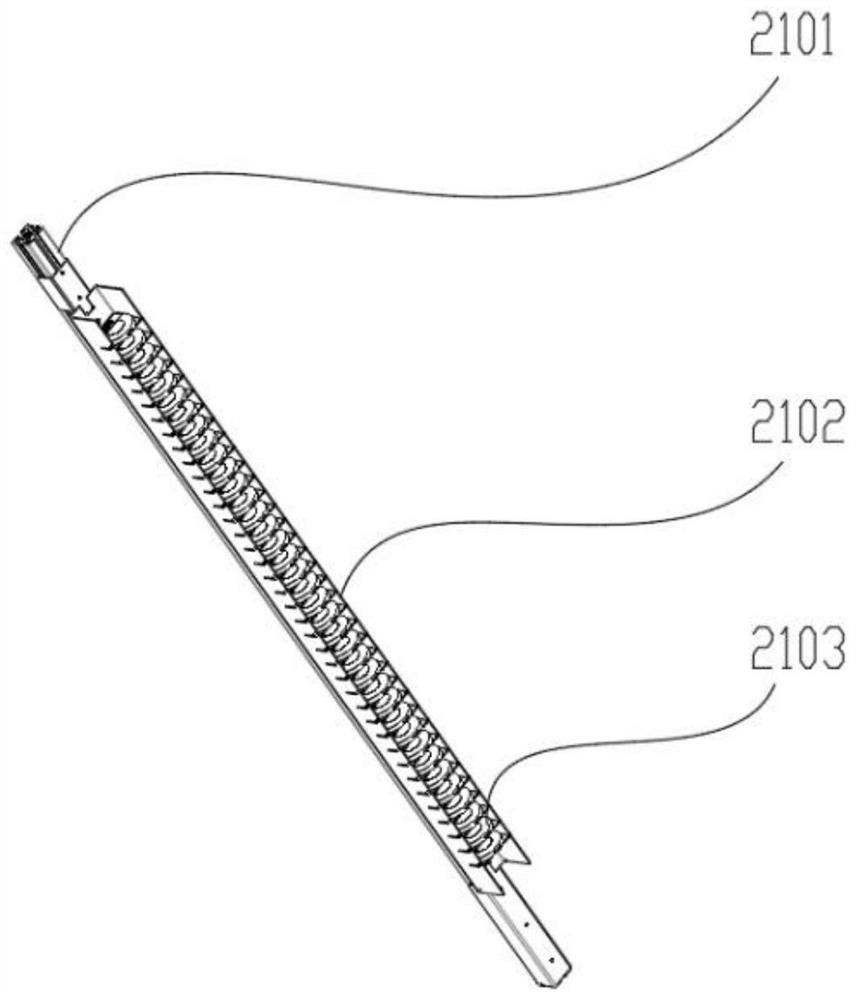

[0042] see Figure 1-8 , the present invention provides a technical solution: dicing knife intelligent material management equipment, including a skeleton 20, a rotating mechanical arm 23 is installed inside the skeleton 20, and at least twenty-one scribing machines in a circular array around the center line of the rotating mechanical arm 23 The blade magazine 21 is equipped with a feeding mechanism 22 on one side of the skeleton 20. The feeding mechanism 22 is used to realize batch loading and unloading of the scribing blades, and the rotating mechanical arm 23 is used to grab the scribing blades and send the scribing blades in order On the scribe blade bin 21, the scribe blade bin 21 is used to realize the storage of the scribe blade;

[0043]The feeding mechanism 22 includes a feeding bin 2201 installed on the skeleton 20, a linear module 2202, a suction nozzle assembly 2203, a pushing away cylinder 2204, a suction nozzle cylinder 2205, a righting cylinder 2206, a righting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com