A capacitor coil processing device

A technology for processing devices and capacitor coils, which is applied in coil manufacturing, circuits, electrical components, etc., can solve the problems of increased workshop area, large processing equipment, and high production and processing costs, so as to save production and processing costs, shorten processing time, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

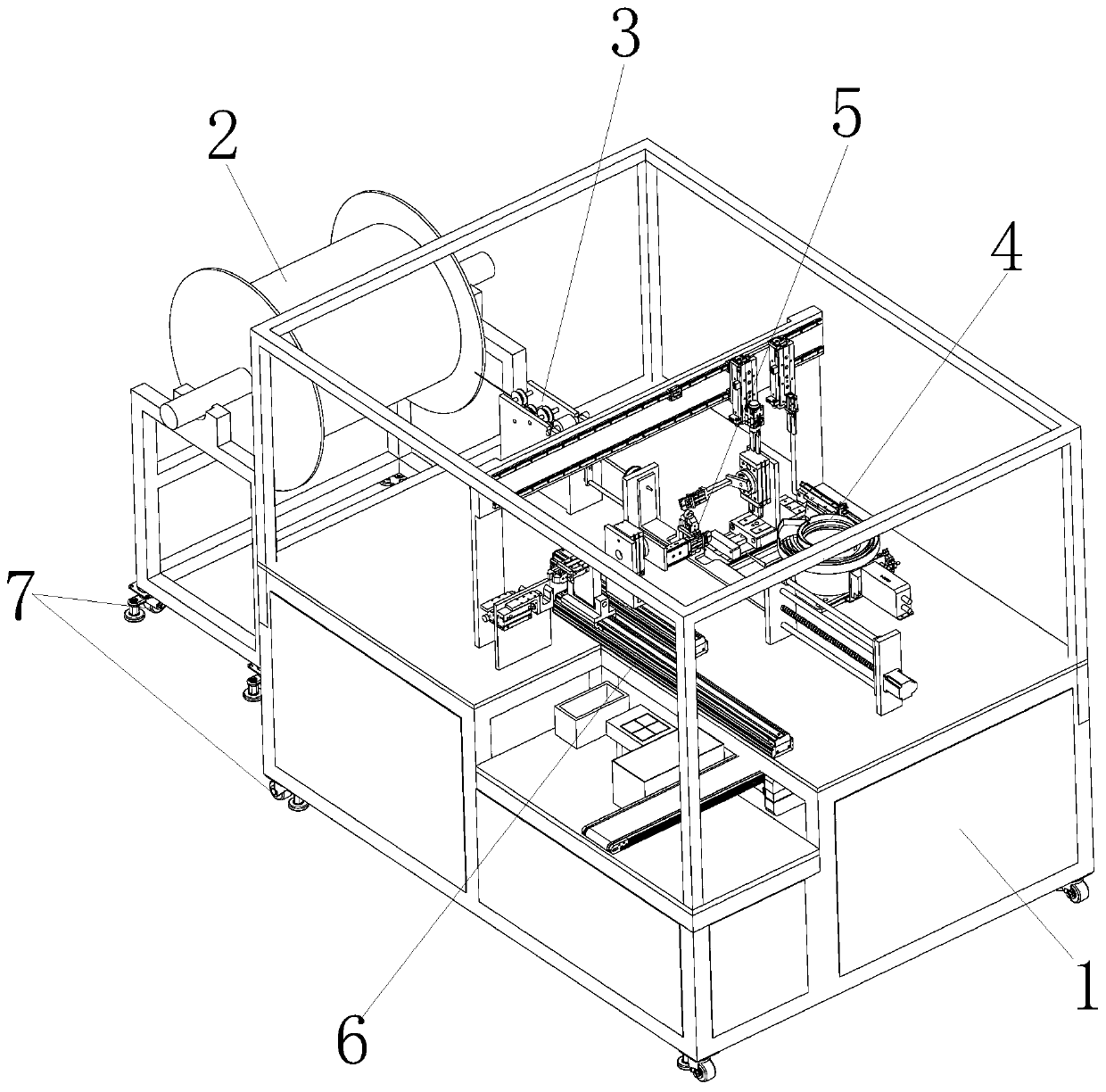

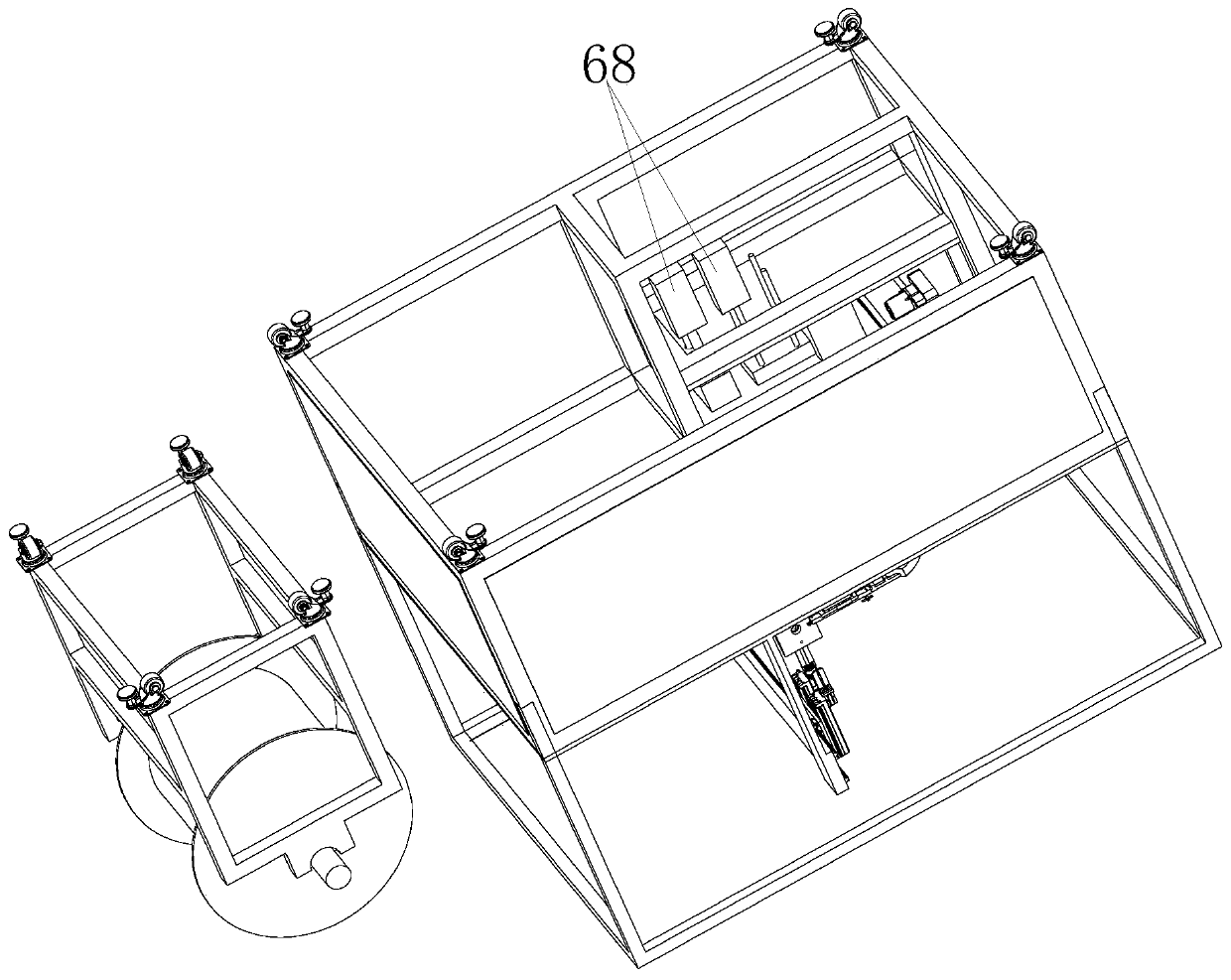

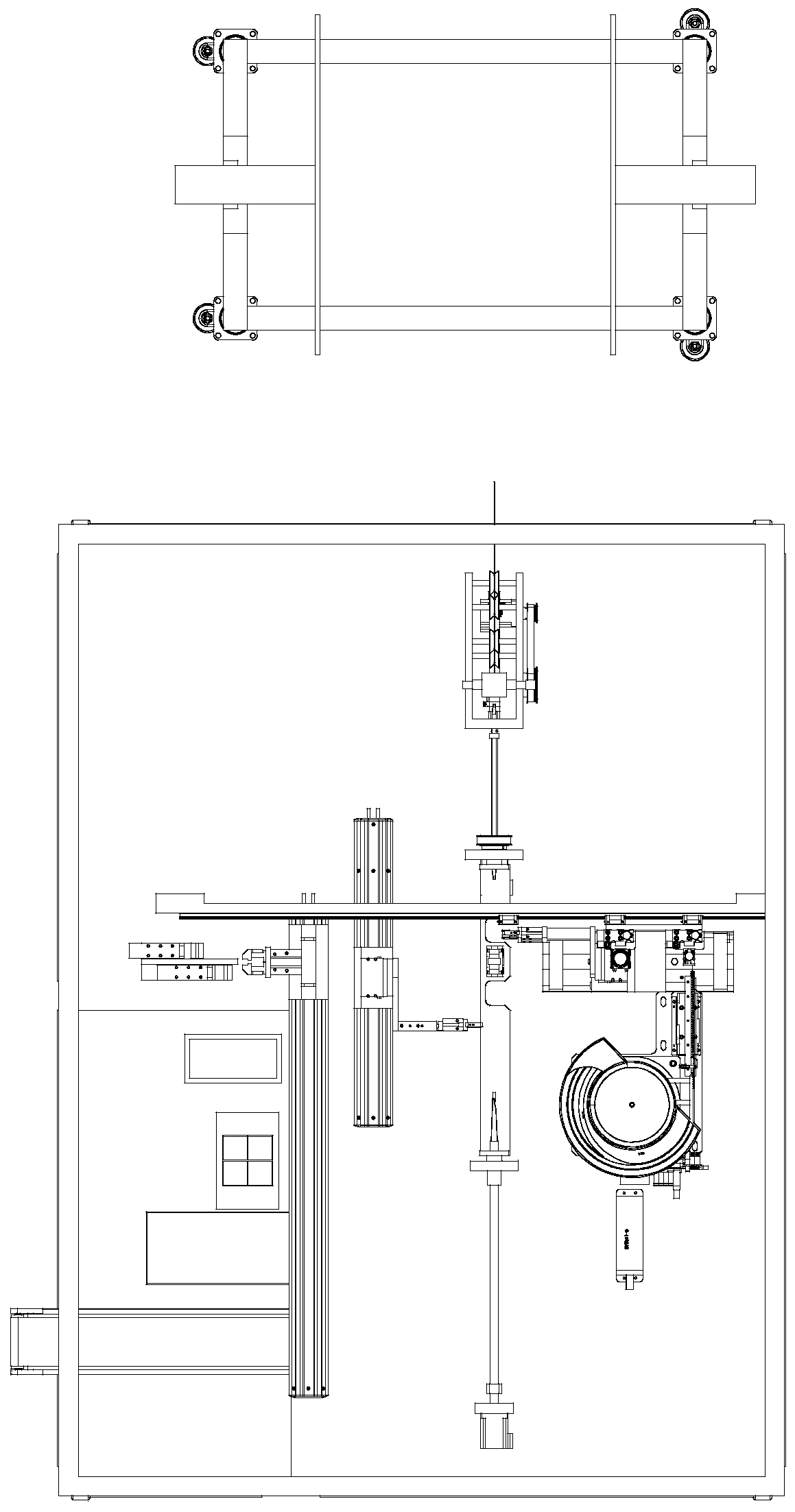

[0031] Such as Figure 1 to Figure 7 As shown, a capacitor coil processing device includes a frame 1, an enameled wire coil 2 placed close to the frame, and the frame 1 is respectively provided with a wire feeding mechanism 3 for receiving the copper wire on the enameled wire coil and Straightening; feeding mechanism 4, used to sequentially deliver the magnetic ring and move the magnetic ring to the corresponding processing station, winding mechanism 5; grab the magnetic ring of the material feeding mechanism and wrap the copper wire in two times On the magnetic ring; the comprehensive processing mechanism 6 is used to complete the final trimming, soldering, testing and unloading of the coil.

[0032] The wire feeding mechanism 3 includes a mounting frame 31, a guide wheel 32 staggered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com