Method for measuring sulfur content in produced gas of sulfur-containing gas well

A determination method and technology of sulfur content, applied in the direction of weighing by removing certain components, can solve problems such as low reference value and inaccurate determination of sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

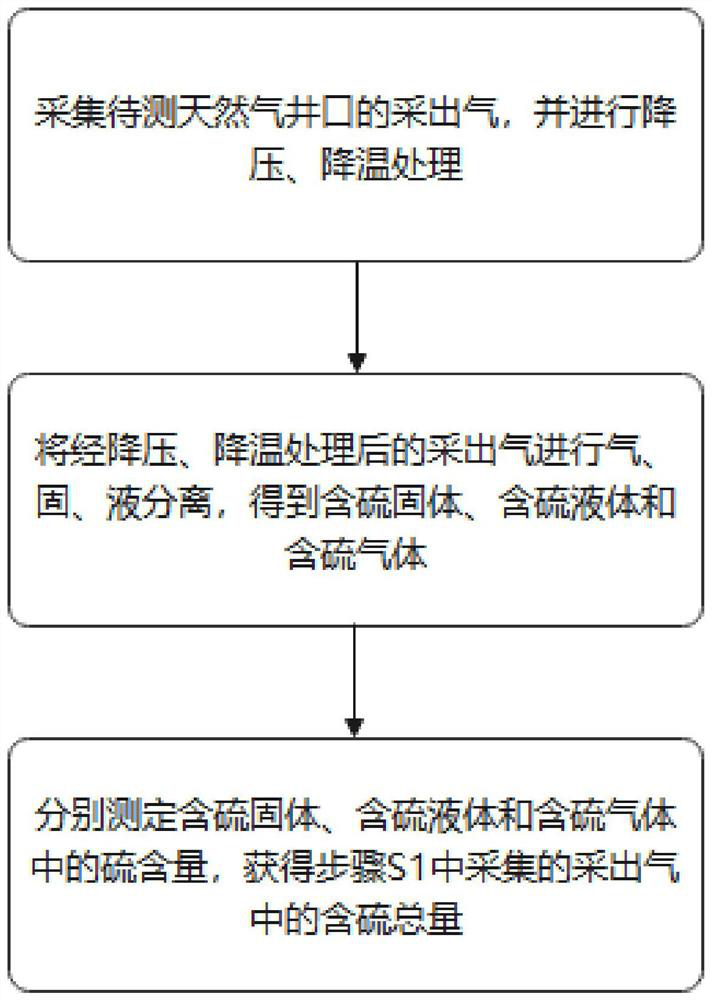

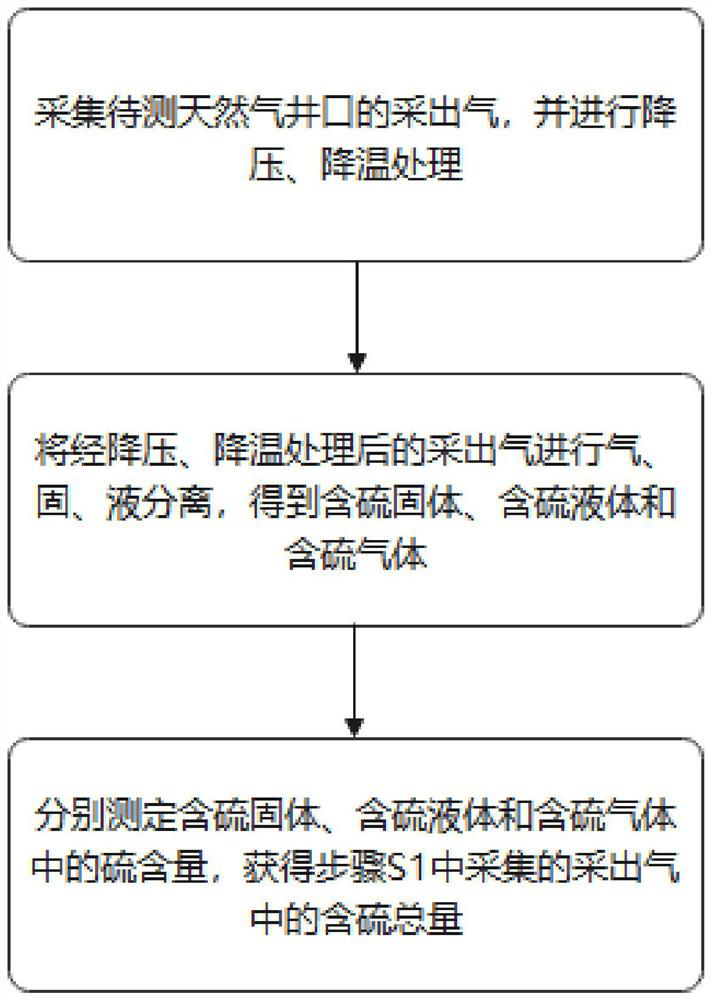

Method used

Image

Examples

Embodiment 1

[0043] Due to the high sulfur content of the produced gas in high-sulfur gas reservoirs, it is necessary to monitor and measure the sulfur content in the produced gas. Moreover, the produced gas of high-sulfur gas reservoirs not only contains hydrogen sulfide gas, but also contains a large amount of elemental sulfur and sulfur-containing organic matter, and the elemental sulfur in the produced gas will be deposited in ground equipment and pipelines, causing serious corrosion of equipment At the same time, sulfur-containing organic sulfur will also cause corrosion of equipment and pipelines during transportation; but in the prior art, the content of hydrogen sulfide gas in the produced gas is usually only measured, and high-sulfur gas content is determined according to the content of hydrogen sulfide gas. Gas well anti-corrosion and anti-blocking measures, so it is difficult to accurately reflect the sulfur content in the produced gas, and it is impossible to provide more valuab...

Embodiment 2

[0068] Embodiment 2 is a further description of Embodiment 1. The same components will not be repeated here. In step S1, before the pressure reduction and temperature reduction of the produced gas, a hydrogen sulfide detector is also used to detect the hydrogen sulfide concentration ρ in the produced gas. g0 ;

[0069] In step S3, the sulfur-containing gas first uses a hydrogen sulfide detector to detect the hydrogen sulfide concentration ρ in the sulfur-containing gas g1 , and then measure the sulfur content in the sulfur-containing gas.

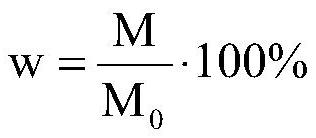

[0070] Then according to the hydrogen sulfide concentration ρ in the produced gas g0 , the hydrogen sulfide concentration ρ in the sulfur-containing gas g1 , the sulfur content in the sulfur-containing liquid, and the sulfur content in the sulfur-containing gas are calculated to obtain the sulfur content ρ in the sulfur-containing organic matter in the produced gas 有机总 ; Realize the determination of hydrogen sulfide content in produced g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com