Silicone hydrogel applied to contact lenses and manufacturing method thereof

A silicone hydrogel and contact lens technology, applied in glasses/goggles, instruments, optics, etc., can solve the problem of not being able to fully improve the lubricity of the PP surface of the lens, and achieve the effect of avoiding foreign body sensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

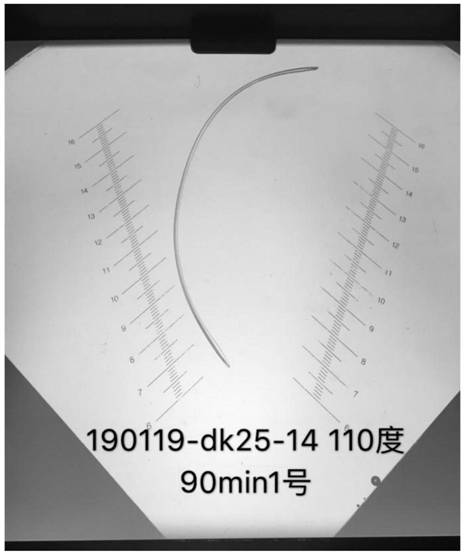

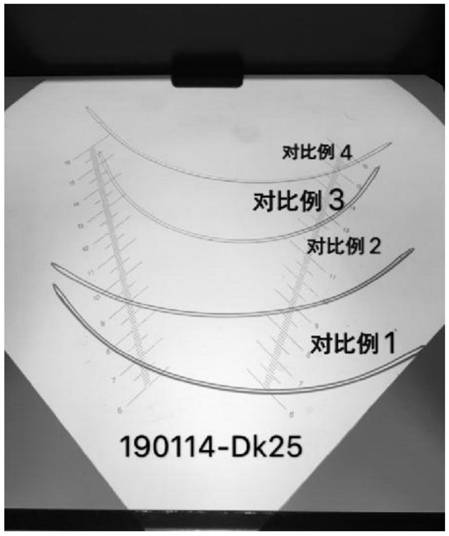

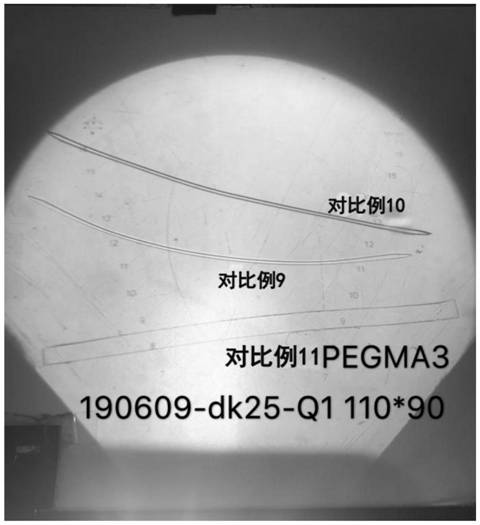

Image

Examples

Embodiment 1

[0045] S1, by weight: 3-methacrylate oxypropyl-tri-(trimethylsiloxy)silane 1.5g, methacrylate-hydroxyethyl ester 4.5g, NVP 2.1g, N-methyl- N-vinylacetamide 1.8g Polyethylene glycol 0.48g, EGDMA 0.097g, AIBN 0.0485g, PVP 0.97g, mPEG-MA 0.78g. Stir the polymerized monomer mixture after configuration for 30 minutes;

[0046] S2. Injecting the polymerized monomer mixture into a molding mold, and molding it under pressure through the mold;

[0047] S3, putting the formed mold into a constant temperature drying oven to cure.

[0048] In Example 1, 3-methacrylateoxypropyl-tri-(trimethylsiloxy)silane is produced by TCI Company, CAS number: 17096-07-0, molecular formula: C16H38O5Si4, molecular weight: 422.81;

[0049] Hydroxyethyl methacrylate is produced by Aladdin Company with a molecular weight of 130.14 and Beilstein No. 1071580;

[0050] NVP (N-vinylpyrrolidone), produced by Sigma Aldrich, molecular formula C 6 h 9 NO, molecular weight 111.14, CAS No. 88-12-0.

[0051]N-meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com