Intercooler and engine waste gas control method and system

A control system and engine technology, applied in the field of vehicles, can solve the problems of reduced engine charge coefficient, damage to spark plugs, pistons and valves, affecting power performance, etc., to achieve optimal heat exchange efficiency, avoid combustion deterioration, and improve heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions herein will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific embodiments described here are only used for explaining the text, rather than limiting the text.

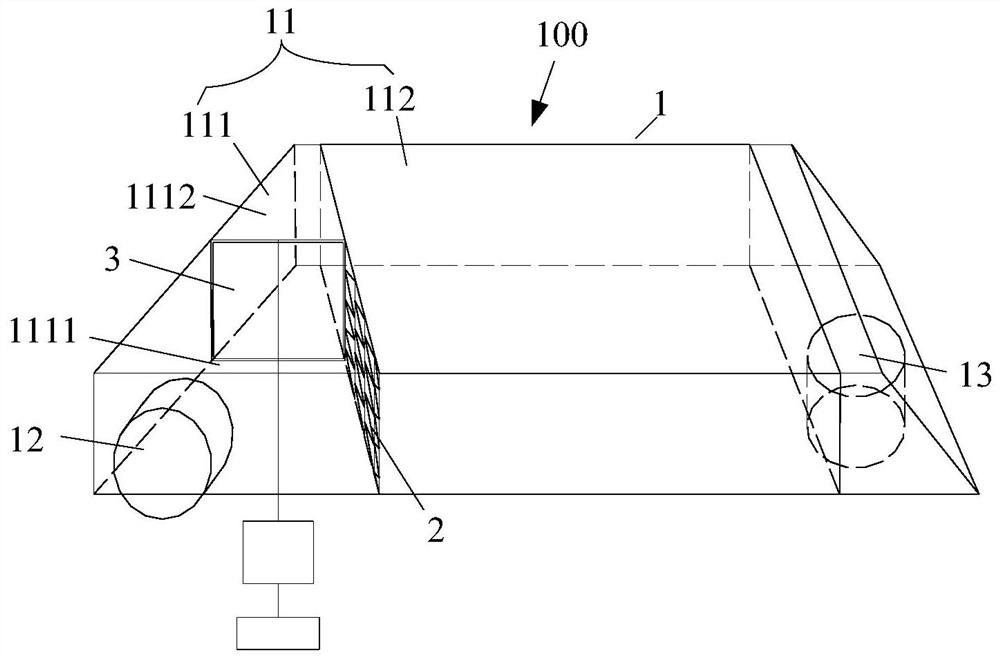

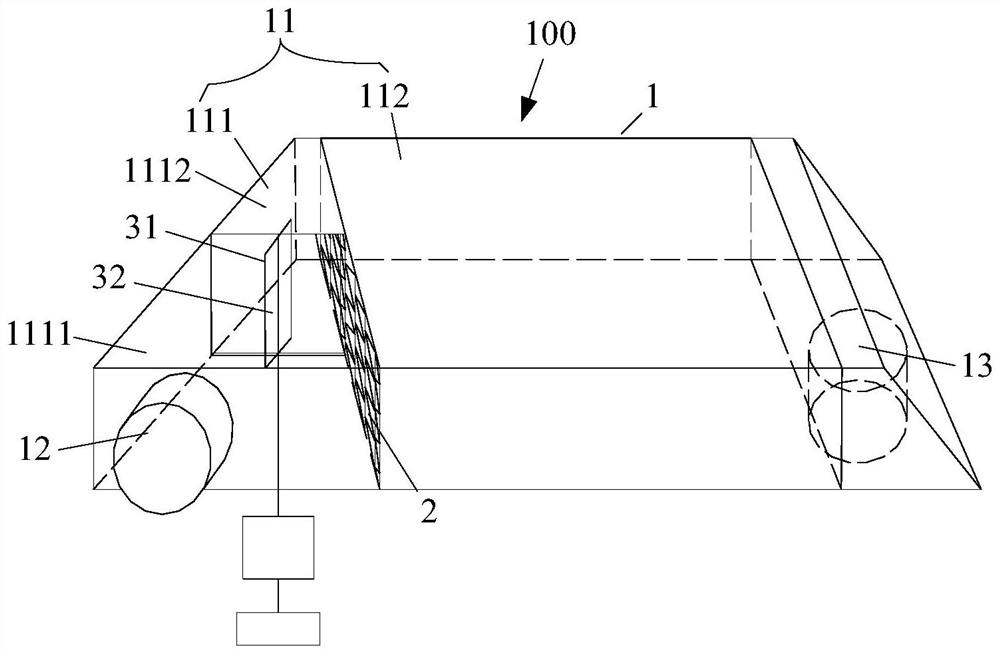

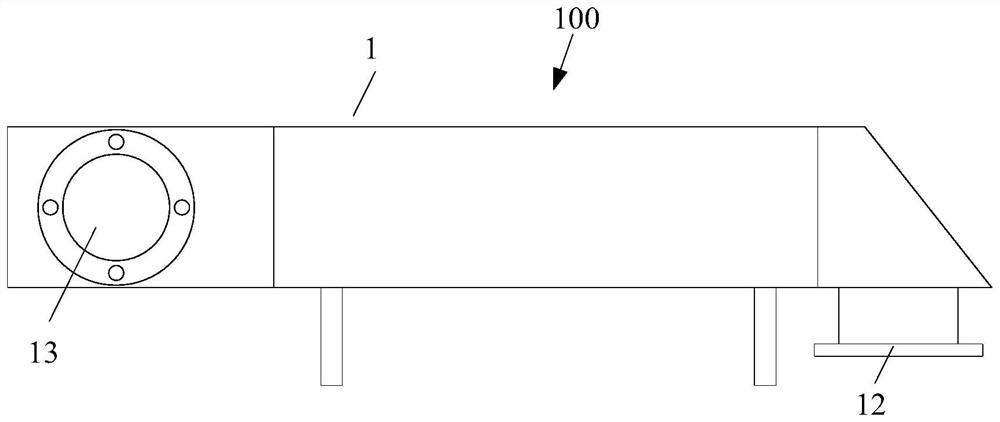

[0034] In one embodiment of this application, as Figure 1-Figure 6 As shown, an intercooler 100 for an automobile is provided. The intercooler 100 is configured to include a shell 1, and the material of the shell 1 can be a common metal, such as steel or aluminum. The housing 1 is provided with a chamber 11 with a certain volume, and the shape of the chamber 11 can be set as a regular cylinder or rectangle. The housing 1 is also provided with an air inlet 12 and an air outlet 13. In order to fully cool the gas flowing through the chamber 11, that is, to increase the contact time or contact area with the cooling liquid in the intercooler 100, The distance between the air inlet 12 and the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com