Environment-friendly wood-plastic composite board extruder and molding method thereof

A wood-plastic composite, green and environmentally friendly technology, applied in other home appliances, flat products, home appliances and other directions, can solve the problems of inconvenient internal cleaning of pipes, shortening the service life of the device, poor stability, etc., to reduce the trouble of installation , The effect of prolonging the service life and smooth transportation channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

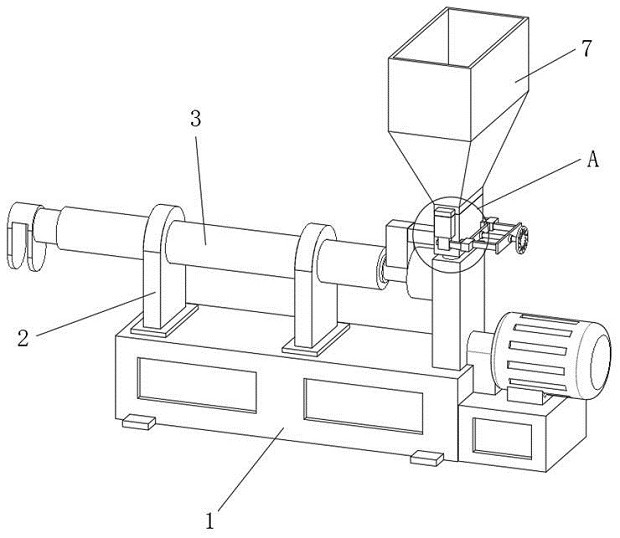

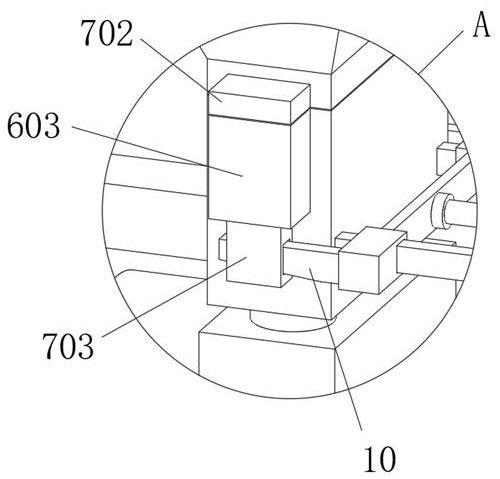

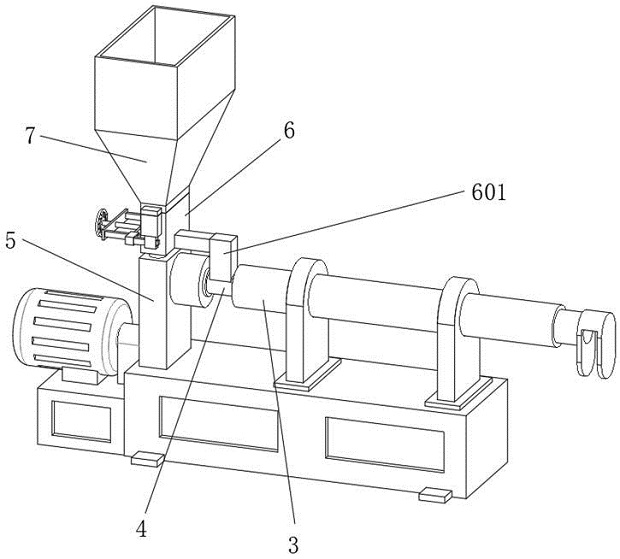

[0038] Example 1: A green and environment-friendly wood-plastic composite sheet extruder and its molding method, including a base 1, an extrusion pipe 3 and a feed hopper 7, the top of the base 1 is fixedly connected with a support 2, and the extrusion pipe 3 The support 2 is fixed above the base 1, the top of the base 1 is fixedly connected with a hollow shell 5, and the side of the extrusion tube 3 close to the hollow shell 5 is fixedly connected with a connecting pipe 4, and the connecting pipe 4 is connected with the hollow shell 5. The side walls of the housing 5 are fixedly connected, and the top of the hollow housing 5 is fixedly equipped with a feeding box 6, and the side wall of the feeding box 6 is fixedly connected with a feeding pipe 601, and the feeding pipe 601 is far away from the feeding box. One end of 6 is fixedly connected on the connecting pipe 4, the feeding hopper 7 is fixedly installed on the top of the feeding box body 6, the two sides of the bottom of t...

Embodiment 2

[0042] Example 2: A green and environment-friendly wood-plastic composite sheet extruder and its molding method, including a base 1, an extrusion pipe 3 and a feed hopper 7, the top of the base 1 is fixedly connected with a support 2, and an extrusion pipe 3 The support 2 is fixed on the top of the base 1, and the extrusion tube 3 can be fixed and supported by the set support 2. The top of the base 1 is fixedly connected with a hollow shell 5, and the extrusion tube 3 is close to the hollow shell. One side of the body 5 is fixedly connected with a connecting pipe 4, the connecting pipe 4 is fixedly connected with the side wall of the hollow shell 5, the top of the hollow shell 5 is fixedly equipped with a feeding box 6, and the side of the feeding box 6 The wall is fixedly connected with a feeding pipe 601, the end of the feeding pipe 601 away from the feeding box 6 is fixedly connected to the connecting pipe 4, the feeding hopper 7 is fixedly installed on the top of the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com