Air cleaning management system for high-speed rail carriage

A management system and air cleaning technology, applied in railway car body parts, railway vehicle heating/cooling, transportation and packaging, etc., can solve the problems of ineffective cleaning of viruses, toxic volatile gases, and dirty gases, and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

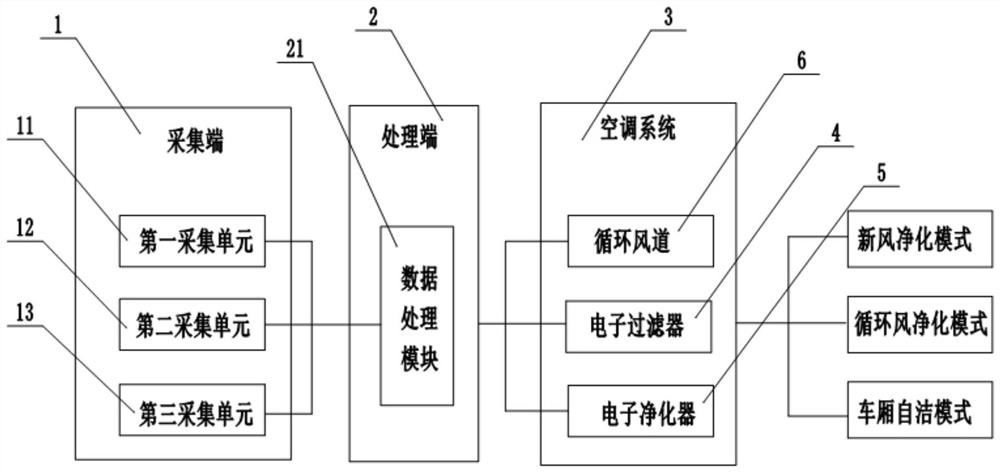

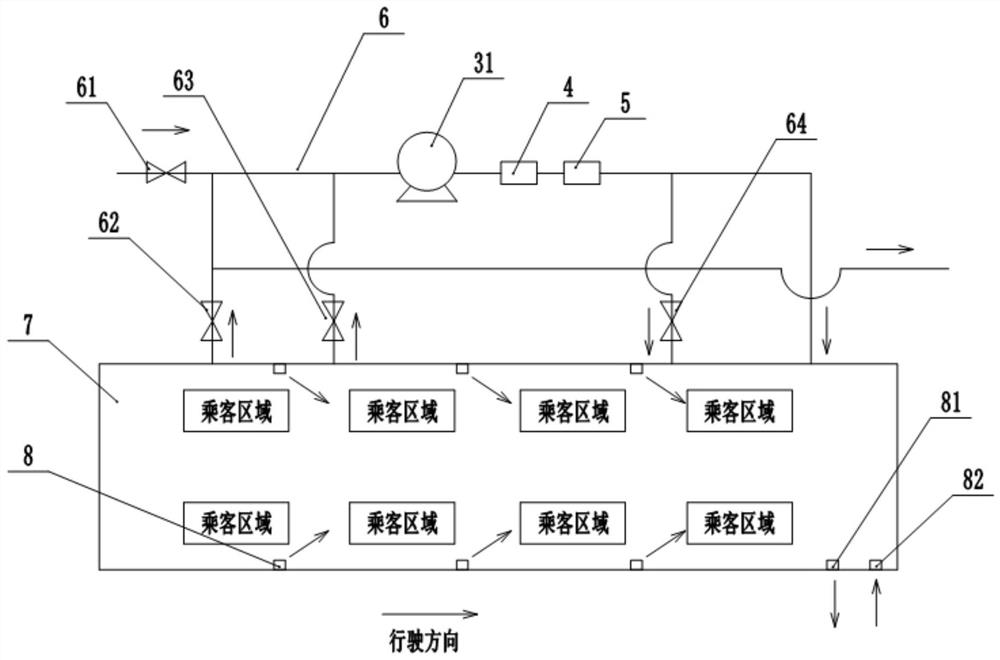

[0041] A kind of air cleaning management system for high-speed rail compartment 7, such as Figures 1 to 2 As shown, it includes an air-conditioning system 3, the air-conditioning system 3 is equipped with a host 31, a circulating air duct 6 and an air purification device, each compartment 7 is independently equipped with a circulating air duct 6, and the circulating air duct 6 is equipped with several first air inlet points 8. The second air inlet point 82 and the air outlet point 81, the first air inlet point 8 and the second air inlet point 82 are respectively used to introduce air into the compartment 7, and the air outlet point 81 is used to export the air in the compartment 7 out of the compartment 7, the first air inlet point 8 is provided with a plurality of and arranged in turn along the length direction of the compartment 7, and each first air inlet point 8 is respectively set in the position corresponding to the window in each compartment 7, and the first air inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com