Cleaning machine for automatically cleaning coat bead or pipes for immunization radiation analysis

A radiation analysis and automatic cleaning technology, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as low efficiency, cumbersome procedures, and poor reliability, and achieve noise reduction, compact structure, and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

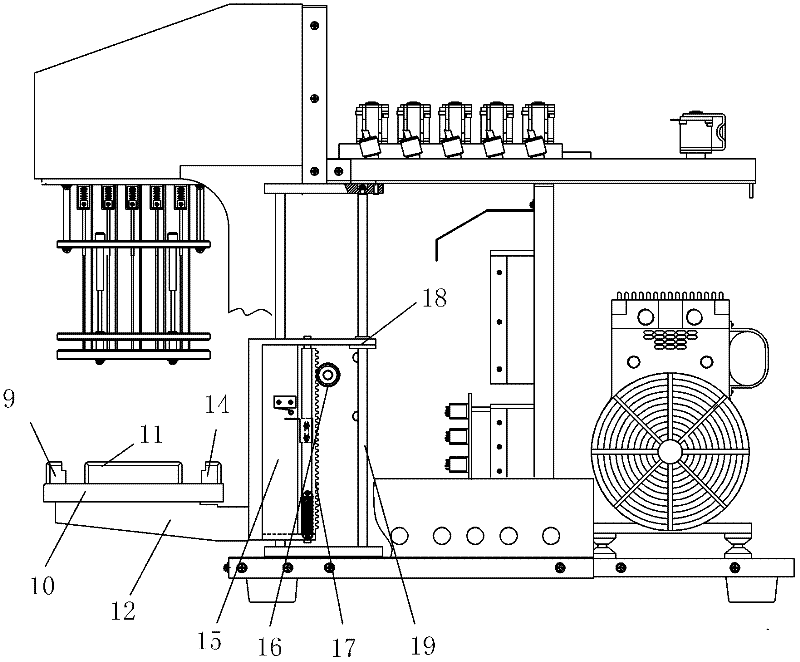

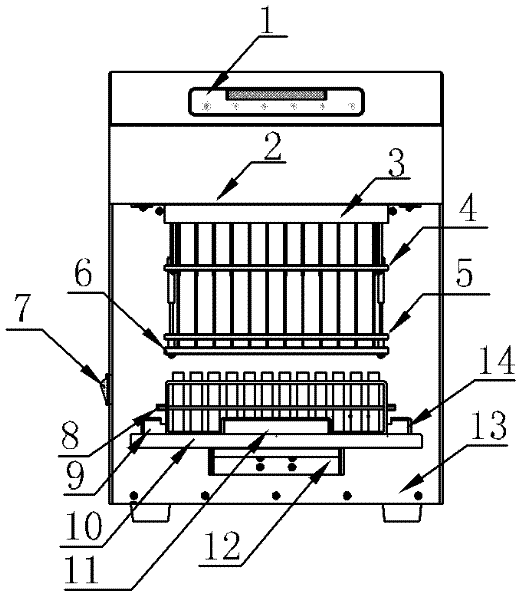

Method used

Image

Examples

Embodiment

[0047] Depending on the shape of the sample to be cleaned, you can choose the automatic washing mode that has been set by the machine (among them: A mode is the test tube washing mode (that is, washing the coated tube or the coated beads placed in the test tube); B mode is the coated bead washing mode (i.e. washing coated beads on trays). Necessary safety checks should be made before automatic washing.

[0048] 1. The operation steps when using mode A are:

[0049] ①Put the test tube rack to be washed on the test tube rack bracket and put the test tubes to be washed in the test tube rack. There are 5 rows in the test tube rack, and each row can hold 12 test tubes. If there are less than 12 test tubes in one row, empty test tubes or discard them Test tubes are topped up to prevent leakage of cleaning solution.

[0050] ② Use the "Mode Selection" key to select A mode.

[0051] ③ Press the "Washing Quantity" (that is, the number of washing rows) key to enter the number of test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com