Left and right drop cloth rack

A cloth drop rack and cloth rack technology, applied in mechanical cleaning, folding thin materials, thin material handling, etc., can solve the problems of inconvenient synchronization, inconvenient cleaning, troublesome proofreading, etc. The structure is simple and the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

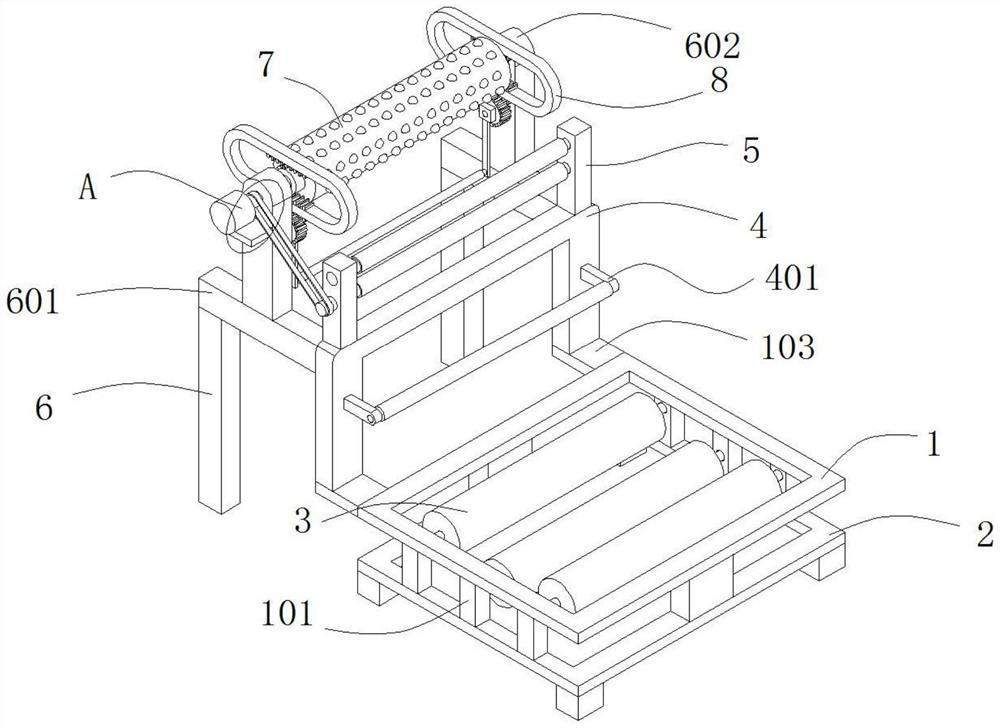

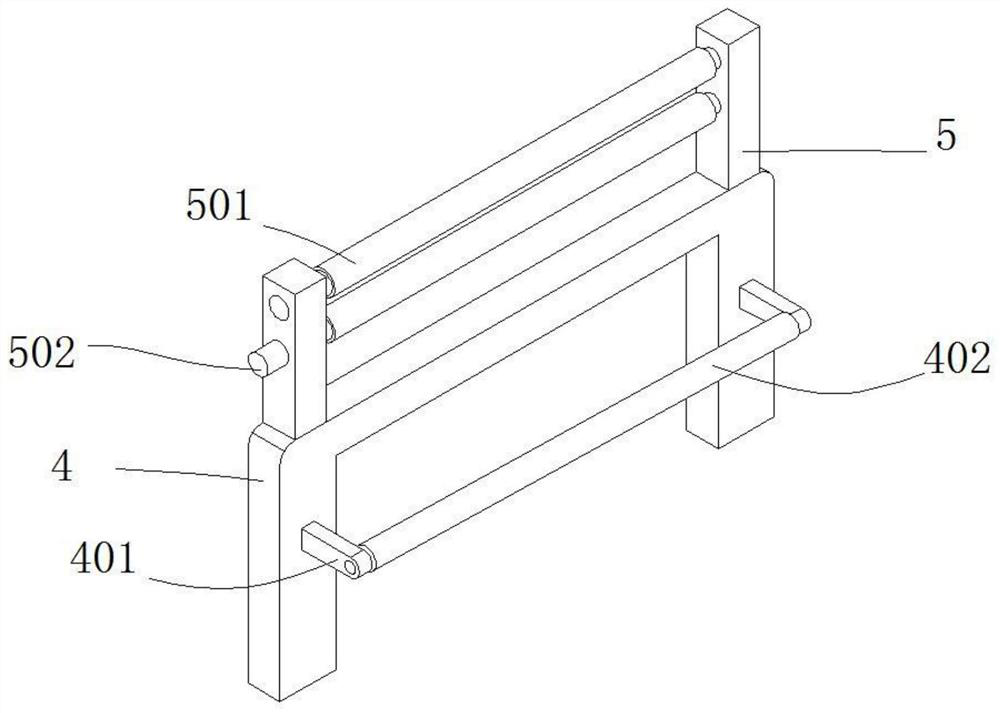

[0031] see Figure 1-8 , the left and right drop cloth racks in this case include:

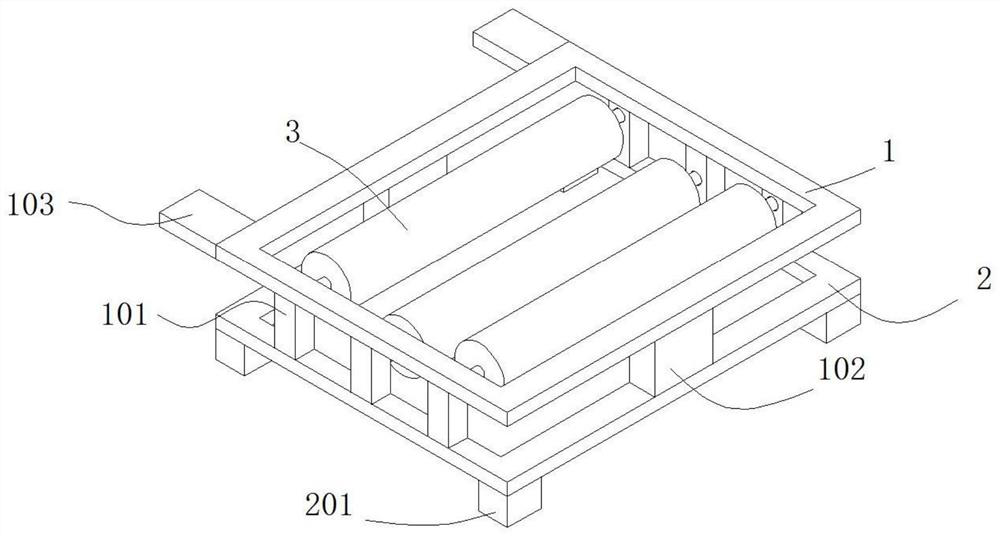

[0032] The cloth release frame, the cloth release frame includes a first support frame 1 and a second support frame 2, between the bottom end of the first support frame 1 and the top end of the second support frame 2, and three supports are fixedly connected on the front and back sides block 101;

[0033] Both the first support frame 1 and the second support frame 2 are a back-shaped square frame, and the shape and size of the first support frame 1 and the second support frame 2 are the same, and the two are stacked symmetrically in the center of the vertical direction, and the three support blocks 101 and the two reinforcing blocks 102 have the same height, which can make the connection between the first support frame 1 and the second support frame 2 more complete, and make the whole cloth placing frame more firm.

[0034] In practical application, between the bottom end of the first suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com