A double-mixed wet-mixed mortar additive

A wet-mixed mortar and additive technology, which is applied in the field of building material admixtures, can solve the problems affecting the shaping and strength performance of wet-mixed mortar, poor composite performance between admixtures, and low engineering applicability, so as to improve the strength performance and reduce the Cracks, the effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

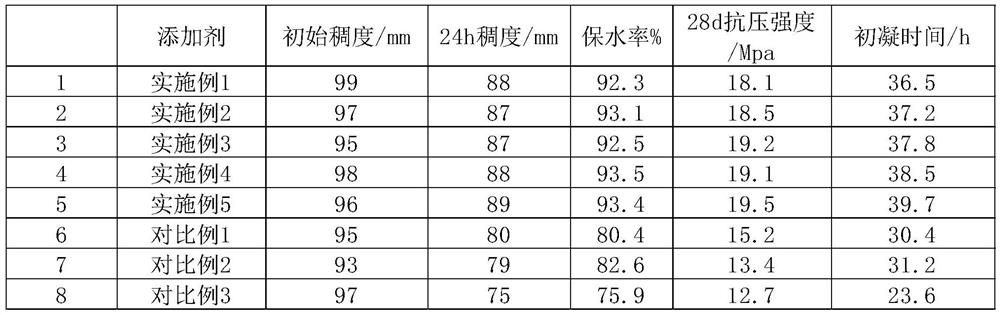

Embodiment 1

[0030] A double-mixed wet-mix mortar additive is prepared from the following raw materials in parts by weight: component A includes 8 parts of a water-retaining agent, 5 parts of a thickener, 1 part of a plastic-preserving aid, 1.5 parts of a strength enhancing component, and a primer. 1 part of gas component; B component includes 10 parts of polycarboxylate water reducer, 5 parts of retarder, and 0.1 part of preservative.

[0031] The water-retaining agent is hydroxypropyl methylcellulose.

[0032] The thickener is sodium carboxymethyl cellulose.

[0033] The retarder is sodium gluconate.

[0034] The air-entraining component is sodium rosin.

[0035] The preservative is sodium benzoate.

[0036] The preparation method of the plastic preservation aid is as follows: weighing 3g of starch, 1g of sodium alginate and 1g of polyvinyl alcohol, adding 80g of distilled water, heating and stirring at a constant temperature of 60°C; after stirring for 10min, adding 5g of acrylamide ...

Embodiment 2

[0040] A double-mixed wet-mix mortar additive is prepared from the following raw materials in parts by weight: component A includes 8 parts of a water-retaining agent, 6 parts of a thickener, 2 parts of a plastic-preserving aid, 2 parts of a strength enhancing component, and a primer. The gas component is 2 parts; the B component includes 10 parts of polycarboxylate water reducer, 6 parts of retarder, and 0.1 part of preservative.

[0041] The water-retaining agent is hydroxyethyl cellulose ether.

[0042] The thickener is starch.

[0043] The retarder is sucrose.

[0044] The air-entraining component is sodium rosin.

[0045] The preservative is potassium sorbate.

[0046] The preparation method of the plastic-preserving aid is as follows: weighing 5g of starch, 3g of sodium alginate and 3g of polyvinyl alcohol, adding 80g of distilled water, heating and stirring at a constant temperature of 70°C; after stirring for 15min, adding 9g of acrylamide and 6g of acrylic acid wa...

Embodiment 3

[0050] A double-mixed wet-mix mortar additive is prepared from the following raw materials in parts by weight: component A includes 10 parts of a water-retaining agent, 6 parts of a thickener, 2 parts of a plastic-preserving aid, 3 parts of a strength enhancing component, and 3 parts of a primer. The gas component is 3 parts; the B component includes 12 parts of polycarboxylate water reducer, 7 parts of retarder, and 0.2 part of preservative.

[0051] The water-retaining agent is hydroxypropyl methylcellulose and hydroxyethyl cellulose ether mixed in a mass ratio of 1:1.

[0052] The thickener is polyvinyl alcohol.

[0053] The retarder is citric acid.

[0054] The air-entraining component is sodium rosin.

[0055] The preservative is sodium benzoate.

[0056] The preparation method of the plastic-preserving aid is as follows: weighing 5g of starch, 3g of sodium alginate and 3g of polyvinyl alcohol, adding 80g of distilled water, heating and stirring at a constant temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com