Noise barrier structure for road construction

A road construction and barrier technology, applied in the direction of noise absorption devices, buildings, etc., can solve the problems of noise energy reduction, large gaps, and the sound absorption principle of the sound-absorbing panel structure is not announced, so as to achieve the effect of isolating water vapor and improving noise elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

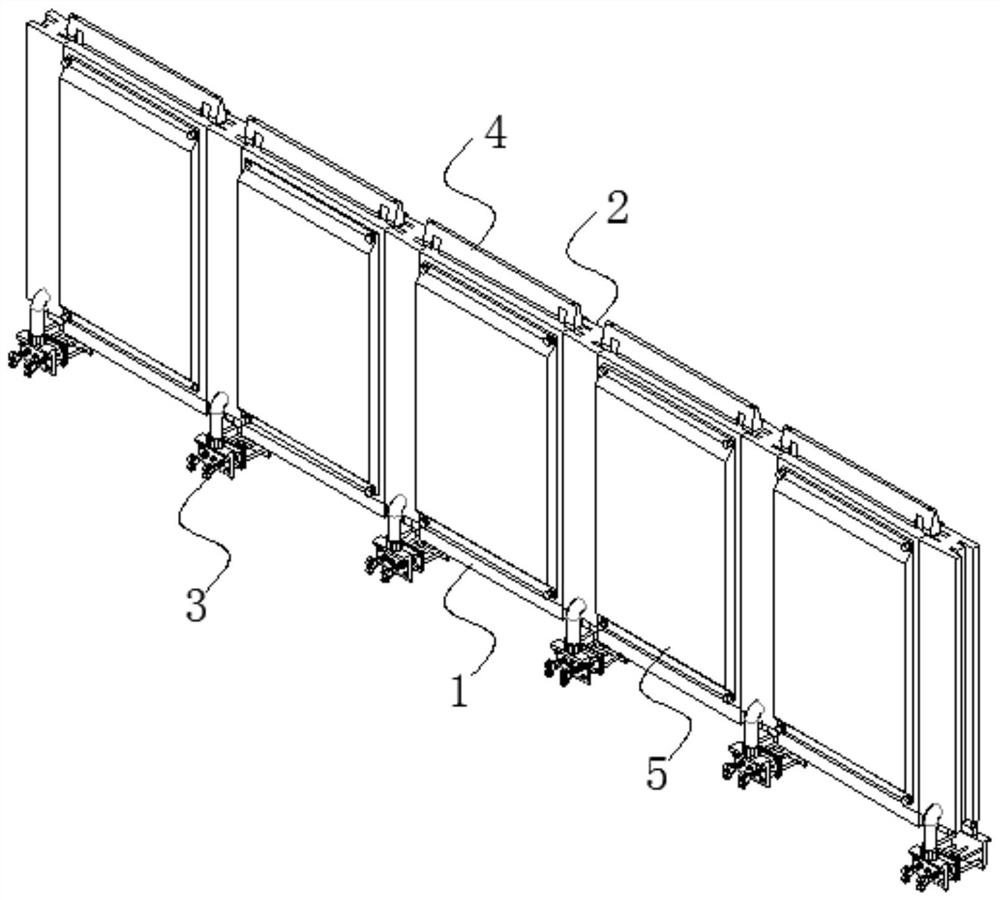

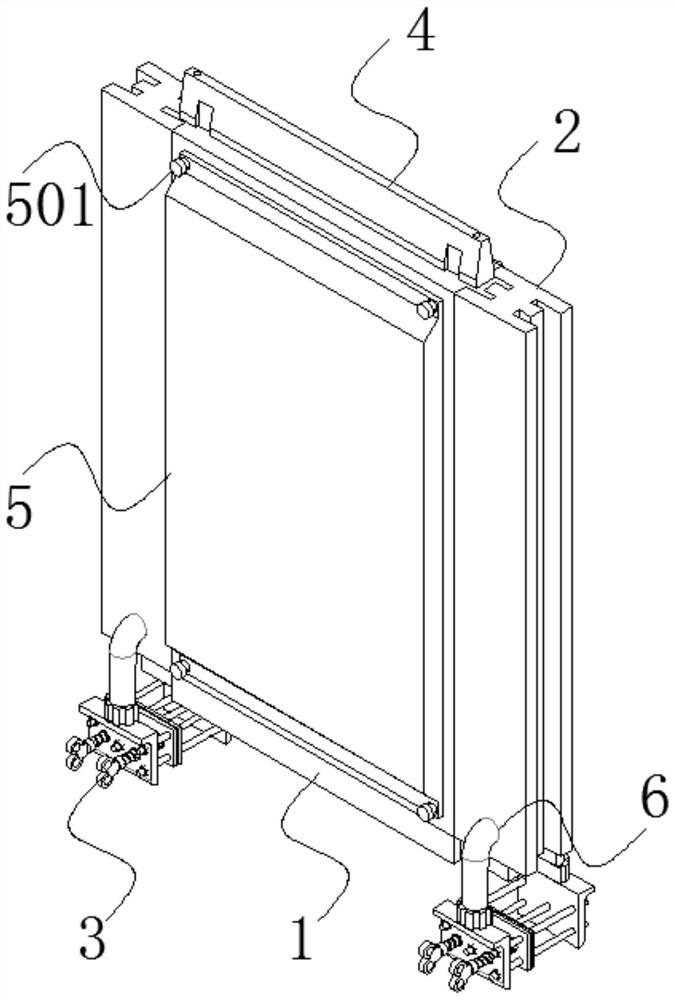

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

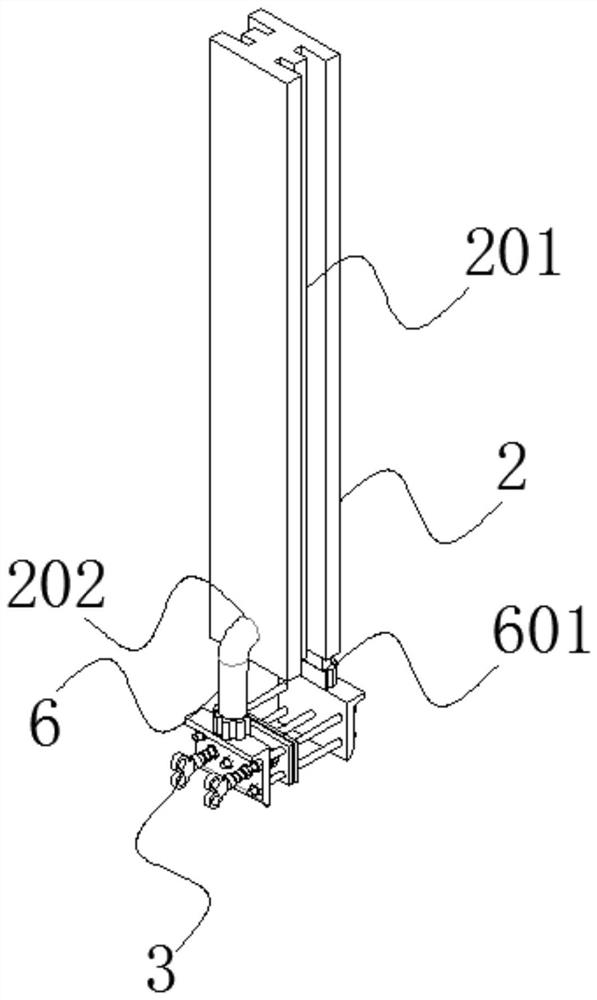

[0040] see Figure 1-3 As shown, the present invention is a road construction noise barrier structure, including a frame body 1, a frame body connecting plate 2, an installation assembly 3 and an inner core body 7, and the frame body 1 is provided with a frame body connecting plate 2 on the left and right sides, The bottom side wall of the frame connecting plate 2 passes through the connecting column 6 and the installation component 3, the front and rear cover plates 5 are inlaid on the front and rear sides of the frame body 1, and the sealing plug plate 4 is inlaid on the top side wall of the frame body 1, and the frame body 1 is inlaid with an inner core body 7;

[0041] Among them, the left and right sides of the frame body 1 are provided with connecting and matching groov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap