Organic photovoltaic cell and preparation method thereof

An organic photovoltaic cell and organic photovoltaic technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as failure of battery components, high transmittance, and increased thickness of organic photovoltaic cells, achieving water vapor isolation, high etching efficiency, The effect of preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

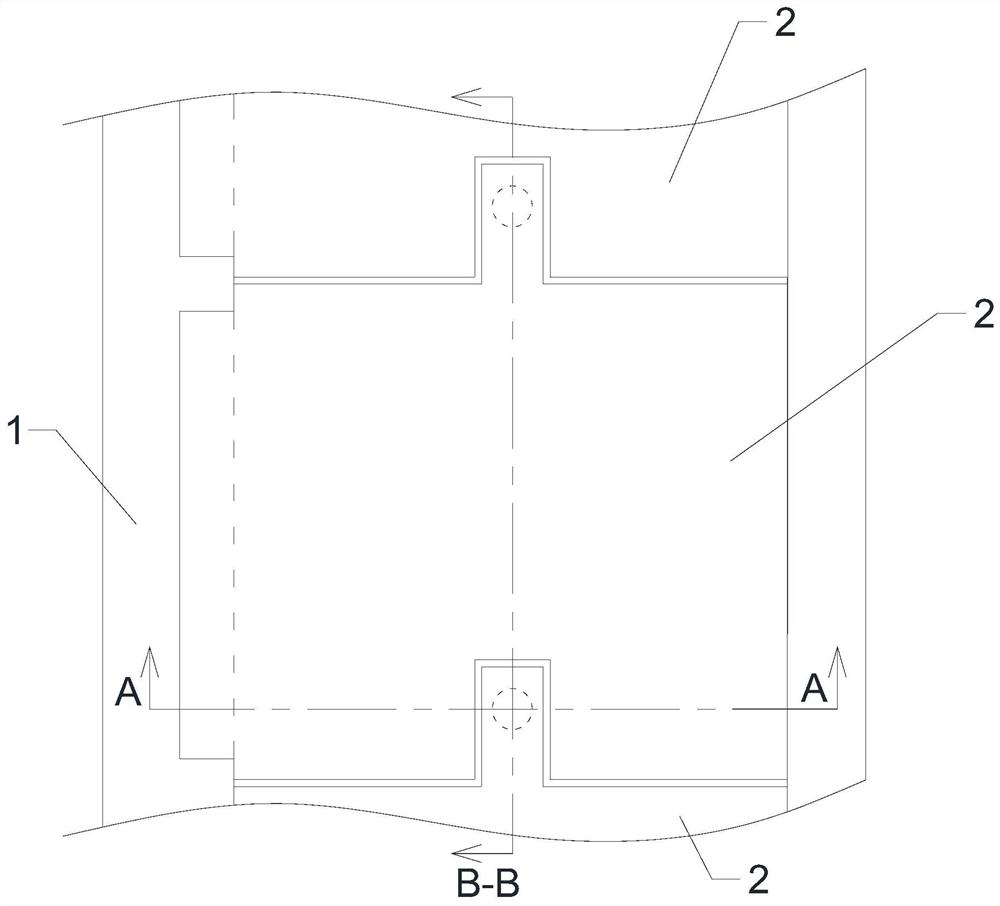

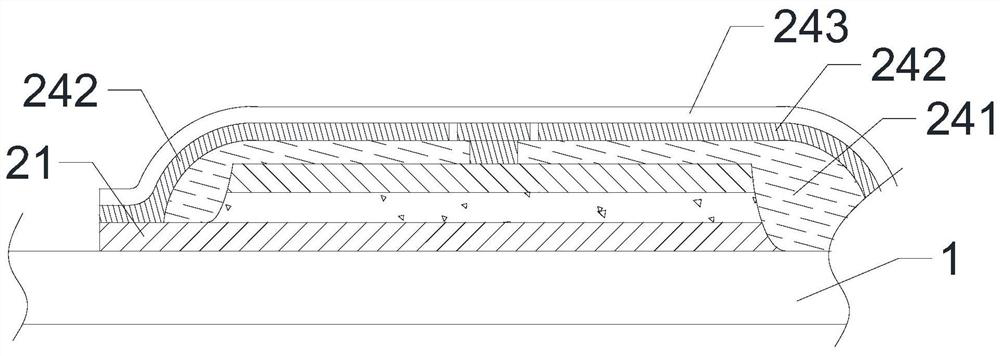

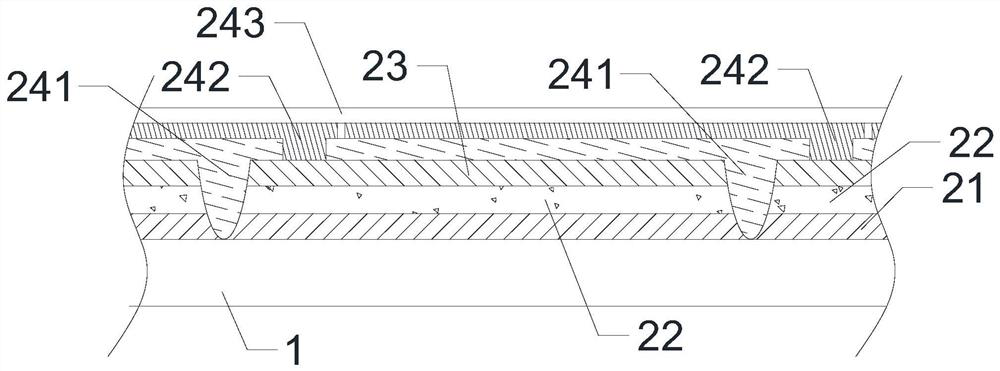

[0052] like figure 1 As shown, this embodiment provides an organic photovoltaic cell, which includes a transparent substrate 1 and at least one organic battery unit 2 formed on the transparent substrate 1. In this embodiment, the at least one organic battery unit 2 It is a single organic battery unit 2 . Each of the organic battery cells 2 includes a transparent front electrode 21, an organic photovoltaic layer 22 and a back electrode 23 stacked in sequence, wherein the organic photovoltaic layer 22 at least includes HTL, ATL and ETL stacked in sequence, and HTL is hole transport. layer, ATL is the active layer, the donor-acceptor mixed solution is obtained by mixing the donor and acceptor materials in a certain proportion, and ETL is the electron transport layer; each of the organic battery cells 2 also includes an encapsulation layer 24 to protect the organic The photovoltaic layer 22 prevents it from being corroded by water vapor. In this embodiment, the encapsulation lay...

Embodiment 2

[0059] like Figure 1-3 As shown, this embodiment is based on Embodiment 1, and is different from Embodiment 1 in that the at least one organic battery unit 2 includes more than two organic battery units 2, that is, the organic photovoltaic cell of this embodiment is It is composed of multiple organic battery cells 2 connected. Further, the adjacent organic battery cells 2 are connected in series through the auxiliary metal layer 242. It can be understood that the auxiliary metal layer 242 covers the insulating layer 241 and is in the same organic battery cell. In 2, the auxiliary metal layer 242 connected to the partially transparent front electrode 211 and the auxiliary metal layer 242 connected to the partial back electrode 231 are arranged separately, that is, the two are insulated; adjacent organic layers are connected through the same auxiliary metal layer 242. Partially transparent front electrode 211 and partial back electrode 231 on battery cell 2 to form a battery c...

Embodiment 3

[0063] like Figure 4 , 5 As shown, this embodiment provides a method for preparing an organic photovoltaic cell, which includes the following steps:

[0064] S11, forming a transparent electrode layer on the transparent substrate 1 and patterning it to obtain a transparent front electrode 21, such as Figure 4 a, shown in 5a.

[0065] The material of the transparent front electrode 21 may be ITO, FTO and AZO, or a transparent high-conductivity material such as conductive polymer or graphene. The transparent electrode layer can be formed by equipment such as PVD vacuum sputtering; then the transparent electrode layer is patterned through a yellow photolithography process to obtain a pattern of the transparent front electrode 21 .

[0066] S12, forming a transition layer on the transparent substrate 1, the top of which is at least higher than the top of the back electrode 23;

[0067] S13, patterning the transition layer to form a plurality of isolation frames 25, each isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com