Buckling type sectional material

A snap-fit, profile technology, applied in the field of building door and window materials, can solve the problems of large glass area, complex structure, uneconomical and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

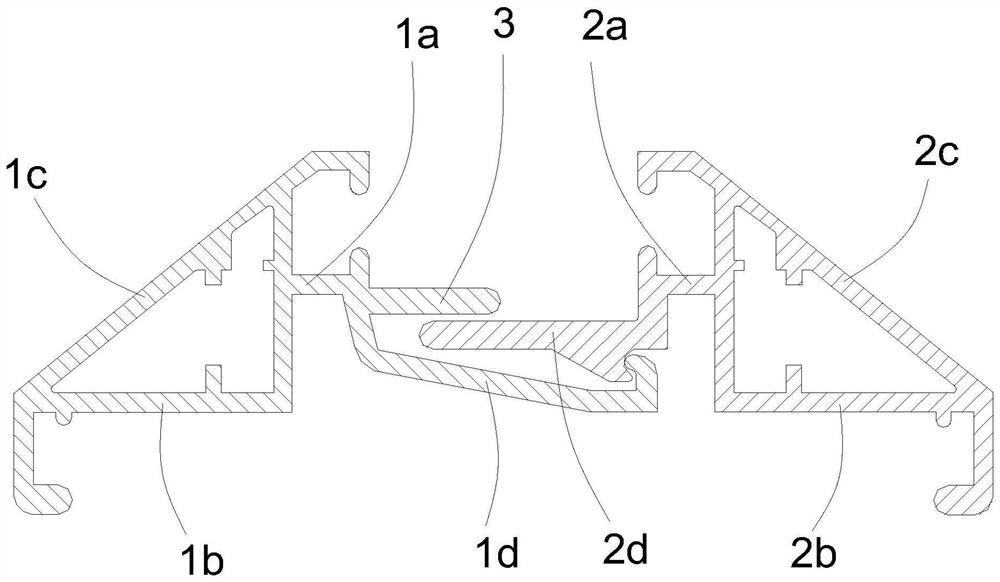

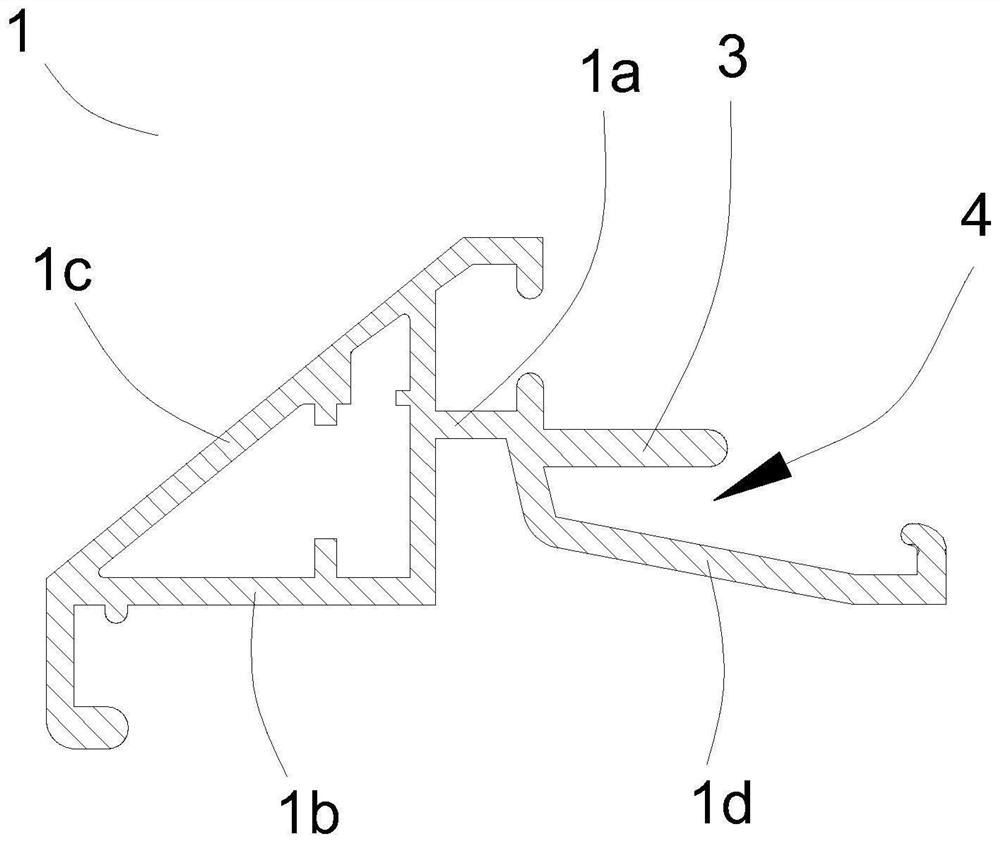

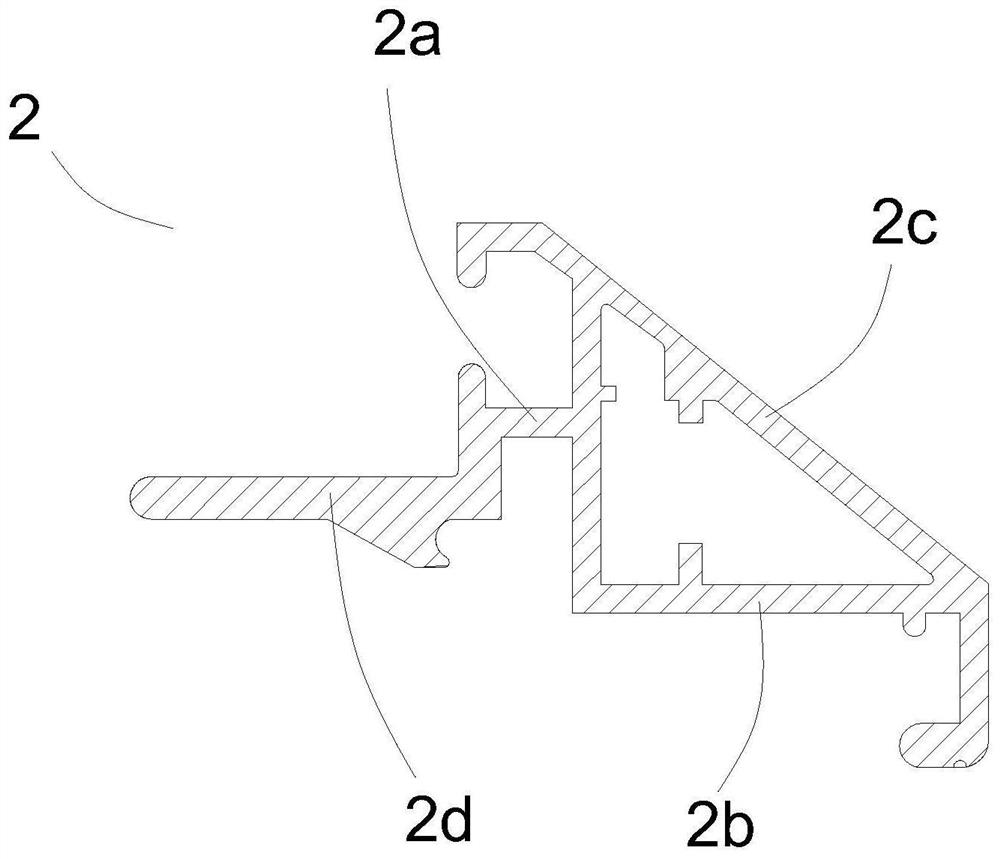

[0030] Please refer to Figure 1 ~ Figure 3 , this embodiment provides a snap-fit profile, which includes a first clamping body 1 and a second clamping body 2, the first clamping body 1 includes a first clamping part and a first connecting part 1d, and the second clamping body The body 2 includes a second clamping portion forming a clamping space with the first clamping portion and a second connecting portion 2d snapped to the first connecting portion 1d.

[0031] In this embodiment, both the first clamping body 1 and the second clamping body 2 are made of aluminum alloy. Because under most environmental conditions, aluminum alloy building profile products have the advantages of high strength, light weight, corrosion resistance, machinability, recyclability, good decoration, long service life, and rich colors. Therefore, it is a good choice to use aluminum alloy materials to make window frame profiles. It can be coated with a layer of 0.007mm Teflon coating on its surface....

Embodiment 2

[0037] Please refer to figure 1 and figure 2 , this embodiment proposes based on the technical solution of Embodiment 1: the first clamping body 1 further includes a limiting portion 3 forming an accommodating cavity 4 with the first connecting portion 1d, and the second connecting portion 2d is interlocked with the first connecting portion 1d After being combined, it can extend into the accommodation cavity 4 .

[0038] In this embodiment, a limiting portion 3 is provided at the end of the first connecting portion 1d away from the hook, and an accommodation cavity 4 is formed between the limiting portion 3 and the first connecting portion 1d, and the accommodation cavity 4 can hold part of the second The connection part 2d is accommodated therein, the purpose of which is to prevent the second connection part 2d from accidentally detaching from the first connection part 1d after the viewing window is installed, resulting in unstable installation.

Embodiment 3

[0040] Please refer to Figure 1 ~ Figure 3, this embodiment proposes based on the technical solution of embodiment 1: a first reinforcing rib 1c is provided between the first window frame matching portion 1a and the first door frame matching portion 1b; the second window frame matching portion 2a and the second door frame matching portion A second reinforcing rib 2c is provided between 2b.

[0041] In this embodiment, in order to enhance the connection strength between the first window frame matching part 1a and the first door frame matching part 1b and the stability of the profile, the above two are connected by the first rib 1c, so that the first A more stable triangular structure is formed among the window frame fitting part 1a, the first door frame fitting part 1b and the first reinforcing rib 1c. Similarly, a second reinforcing rib 2c is also added between the second window frame matching portion 2a and the second door frame matching portion 2b. In addition, it can als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com