Vertical recovery rocket tank pressure supplementing and air sealing system design

A system design and gas sealing technology, applied in the aerospace field, can solve problems such as increasing manufacturing costs and reducing the total weight of the system, and achieve the effect of improving the efficiency of the rocket, reducing the total weight of the system, and simplifying the overall complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, further description will be made below in conjunction with specific examples.

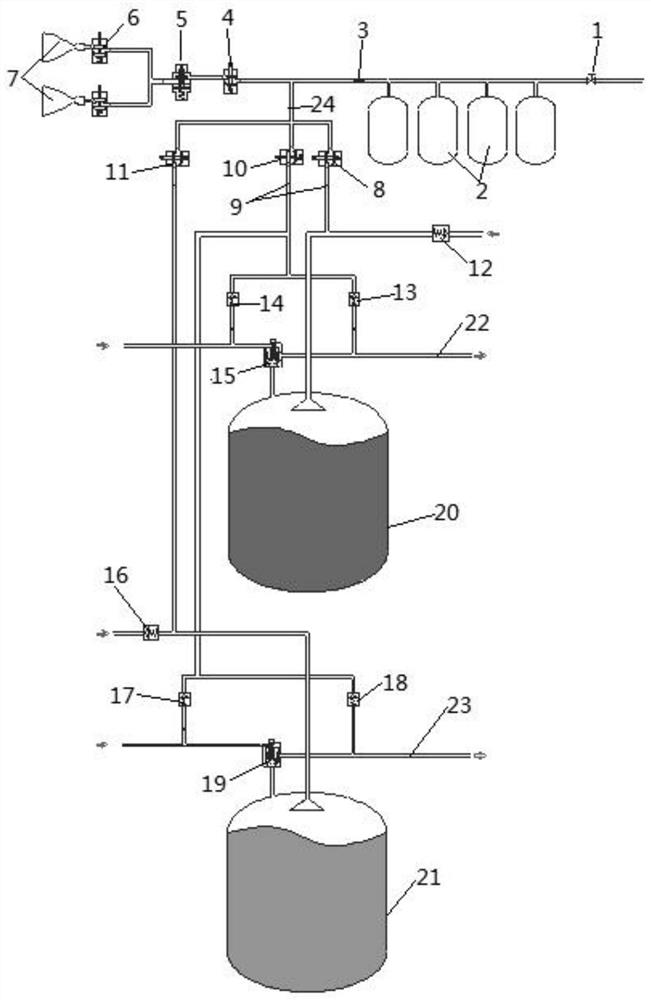

[0021] The present invention proposes a design of supplementary pressure and air seal system for a vertical recovery rocket storage tank, comprising the following steps:

[0022] S1. Set up the auxiliary power system, which includes gas cylinders, auxiliary power system main circuit solenoid valves, pressure reducing valves and multiple thrust chambers in sequence along the gas supply direction of the pipeline;

[0023] S2. Set up a branch pipeline between the gas cylinder and the main solenoid valve of the auxiliary power system, connect and supply gas to the tank pressure supplement system and the tank air seal system through the pipeline;

[0024] S3. During the flight of the rocket, the gas cylinder supplies air to the auxiliary power system to meet the attitude control requirements, and at the same time supplies air to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com