Scalable hubcap with connecting rod hinge assembly and working method thereof

A hinge assembly and hubcap technology, which is applied to wind turbines, wind energy power generation, wind turbines and other directions that are consistent with the wind direction, can solve the problems of low maintenance operation efficiency, difficult disassembly, and large platform size, and achieves reduced operation difficulty and increased production. Large working area, convenient and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

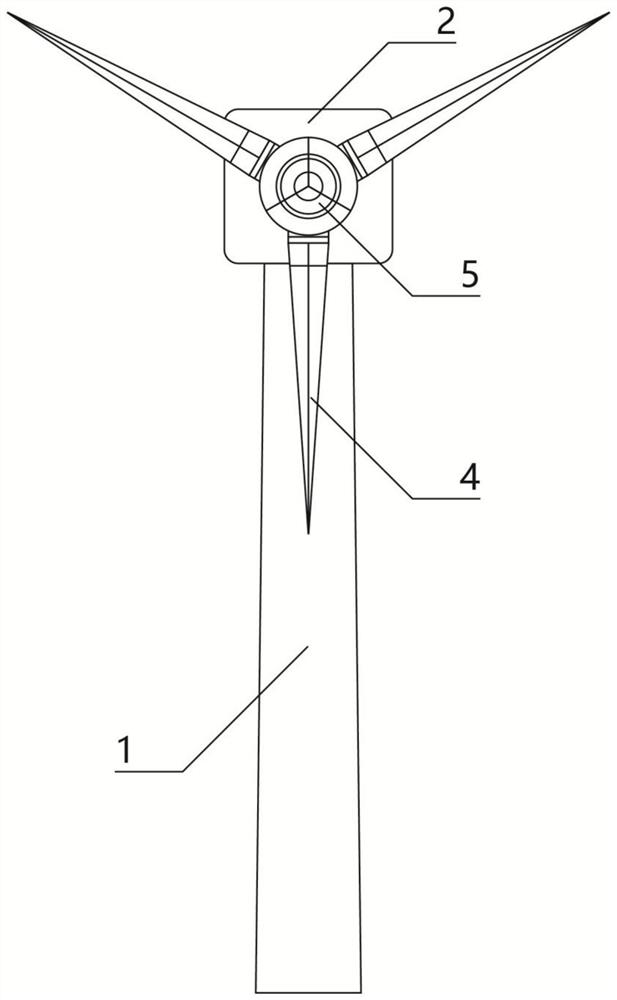

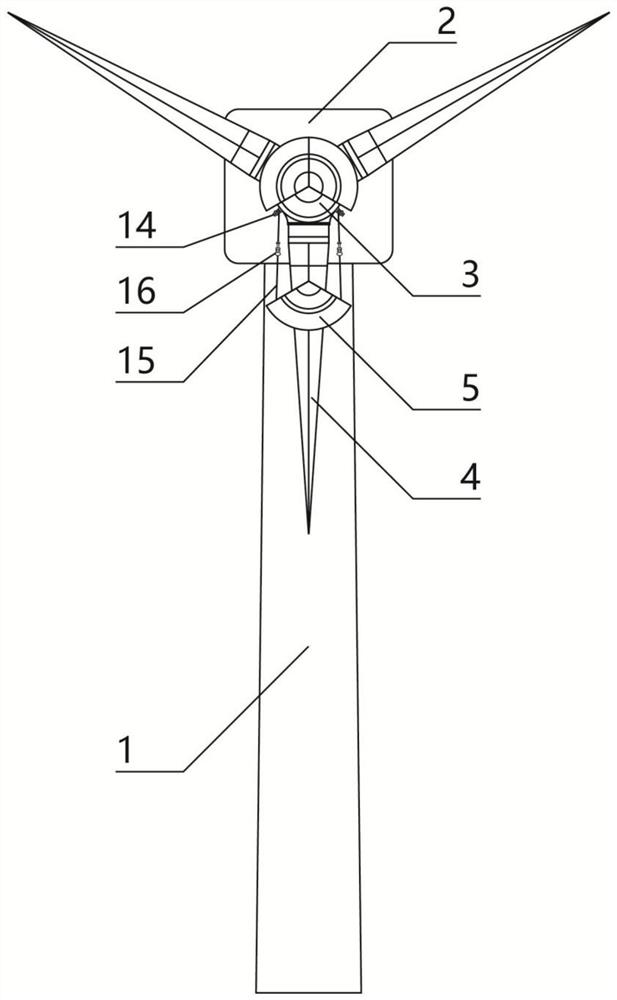

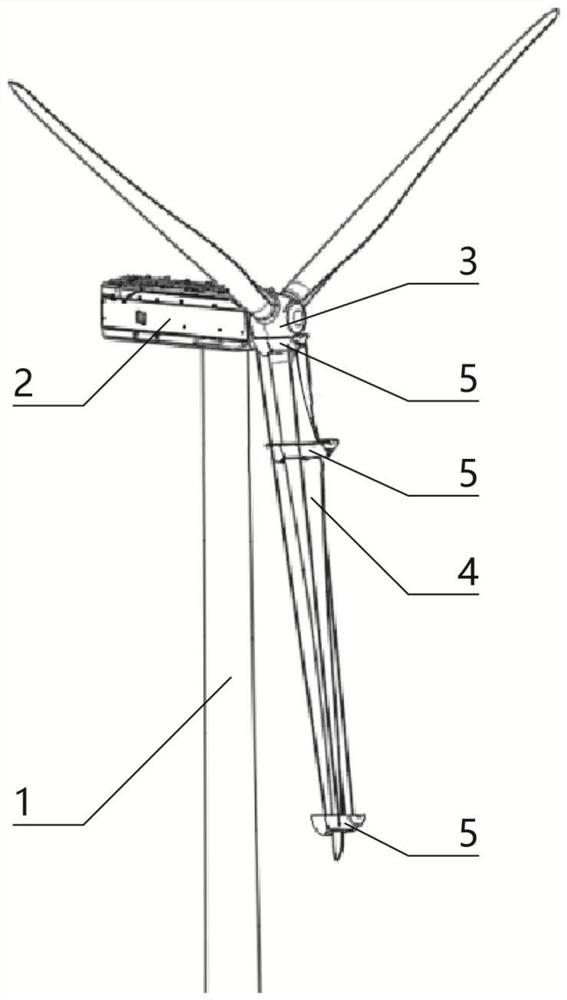

[0046] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 A scalable hubcap with a connecting rod hinge assembly is shown, which is characterized in that it includes a tower 1, a nacelle cover 2, a blade rotator 3, three blades 4 and three hubcap sets 5, the The nacelle cover 2 is located on the top of the tower tube 1, the nacelle cover 2 is fixedly connected with the tower tube 1, the fan blade rotator 3 is located on one side of the nacelle cover 2, and the fan blade rotator 3 and the nacelle cover 2 are Fixedly connected, the three blades 4 are evenly distributed on the outside of the fan blade rotator 3 at the same distance between them, and the three blades 4 are all fixedly connected to the fan blade rotator 3, and the three hubcap sets 5 are respectively loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com