Method for predicting water accumulation amount of goaf filled with water in loess

A prediction method and goaf technology, applied in the field of safety engineering, can solve problems such as limited scope of application, difficulty of analogy, difficulty in satisfying and other problems, and achieve the effect of wide application range, high precision, simple and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

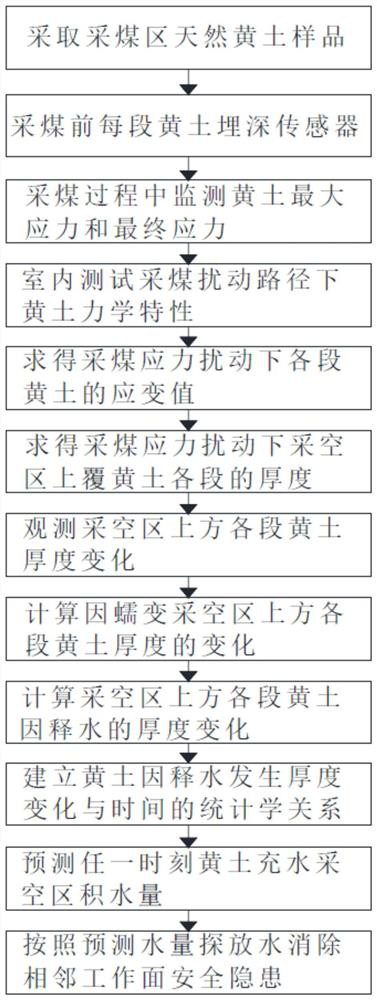

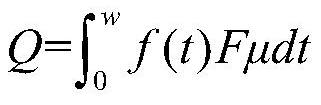

Method used

Image

Examples

Embodiment

[0059] The surface of a mine in northern Shaanxi is covered by thick layers of loess, and water resources are generally scarce. However, after coal mining, there is often a lot of water in the goaf. Due to the complex situation of water accumulation in the goaf, it is impossible to determine whether the water accumulation is fully explored and released. Therefore, it is necessary to predict the accumulation of water in the goaf, specifically for the N5204 coal mining face, which mines 5-2 coal, and the specific steps are as follows:

[0060] Step 1: Before coal mining, obtain loess samples in the full depth range of the coal mining area through drilling.

[0061] Step 2: Before coal mining, bury the stress sensor in the loess, including the following process:

[0062] Every 1-10 meters in the vertical direction of the loess is a section, and one stress sensor is buried in each section, and n=12 are buried in total, that is, the loess is divided into 12 sections. Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com