Fuse wiring structure and wiring method thereof

A wiring structure and fuse technology, which is applied in the direction of electrical component structure association, transformer/inductor coil/winding/connection, etc., can solve the problems of aggravating the aging and decomposition of transformer oil inside the box transformer, unfavorable box transformer stable operation, etc., to avoid The effect of overheating of the fuse, reducing the cost of the box and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

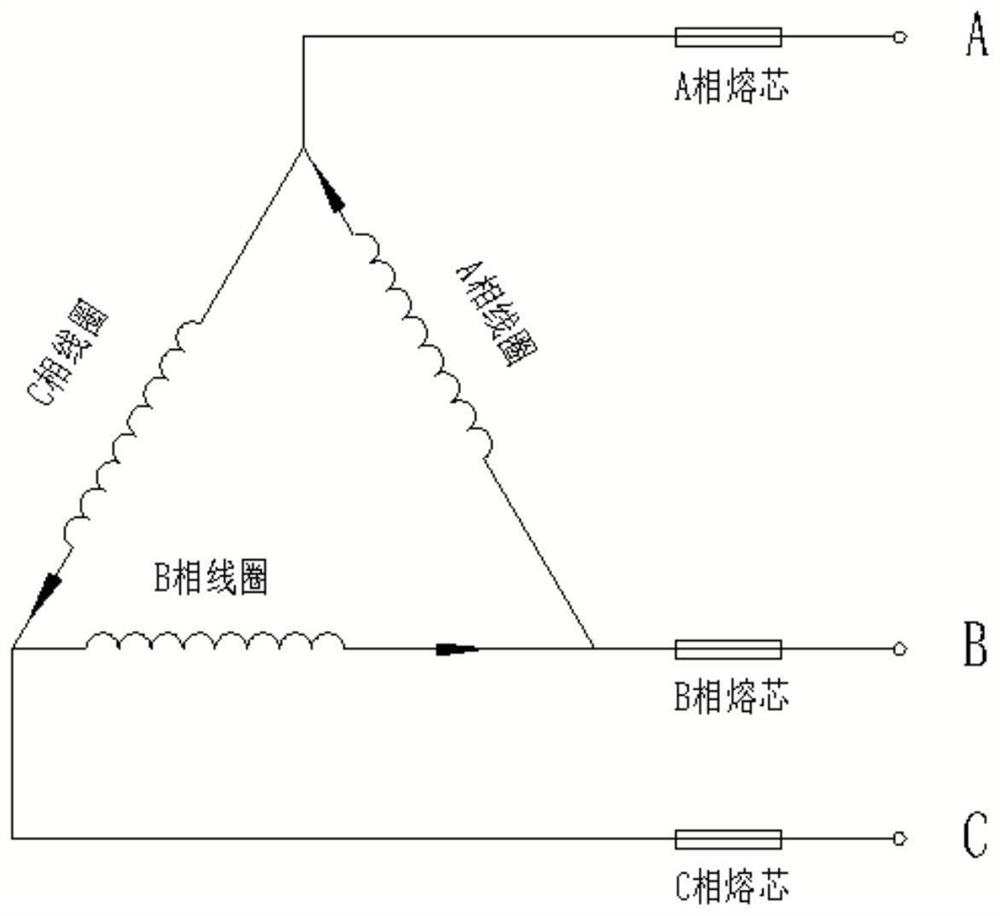

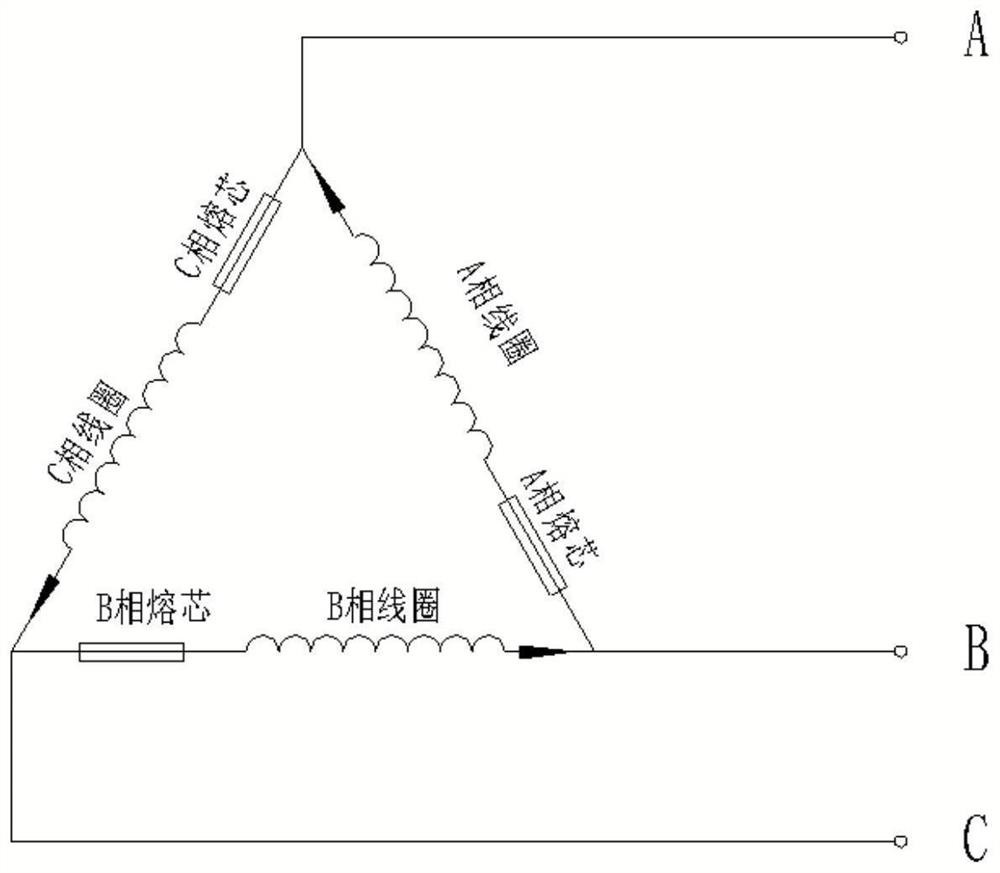

[0026] This embodiment provides a fuse wiring structure, such as image 3 As shown, it includes three-phase transformer coils. The three-phase transformer coils include A-phase coils, B-phase coils, and C-phase coils connected end to end in sequence. The three-phase transformer coils are connected in a delta, and the combination of adjacent two-phase transformer coils The points are drawn as the three phase lines of the three-phase transformer; the fuse wiring structure also includes A-phase fuses, B-phase fuses and C-phase fuses connected in series with the A-phase coil, B-phase coil and C-phase coil respectively .

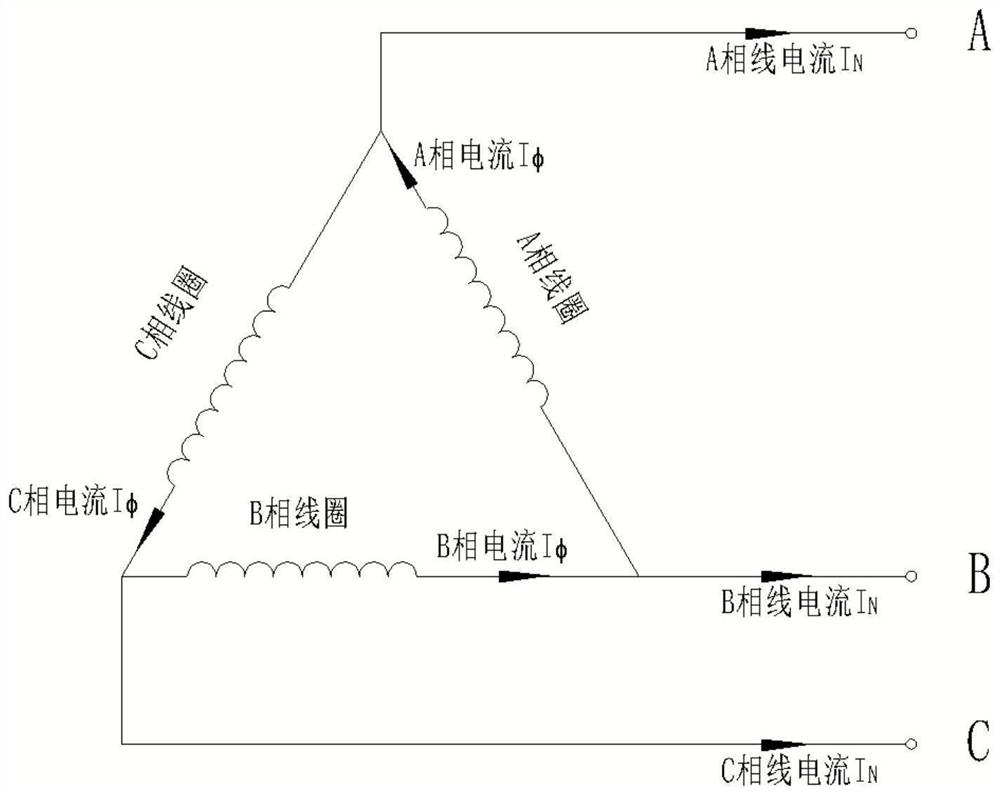

[0027] This embodiment can reduce the rated current of the fuse, reduce the cost of the box-type transformer, and facilitate the stable operation of the box-type transformer. Specifically, such as figure 1 shown in I Φ Indicates the phase current (referring to the current flowing through each phase coil in the three-phase transformer), expressed in I N Indica...

Embodiment 2

[0038] This embodiment provides a wiring method as in any one of the fuse wiring structures in Embodiment 1, including:

[0039] Connect the A-phase coil, B-phase coil and C-phase coil end-to-end in order to form a triangle connection, and lead out the joint points of the adjacent two-phase coils as the three phase lines of the three-phase transformer;

[0040] Connect the A-phase fuse, B-phase fuse and C-phase fuse in series with the A-phase coil, B-phase coil and C-phase coil respectively to obtain the fuse wiring structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com