Modularized error code testing device

A bit error testing and modularization technology, applied in the field of communication, can solve problems such as connector falling off, failure to ensure consistency, damage to connector connection strength, etc., to achieve enhanced deformability, avoid unqualified appearance, and ensure close contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

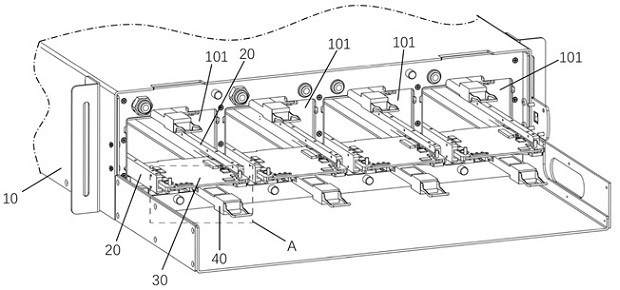

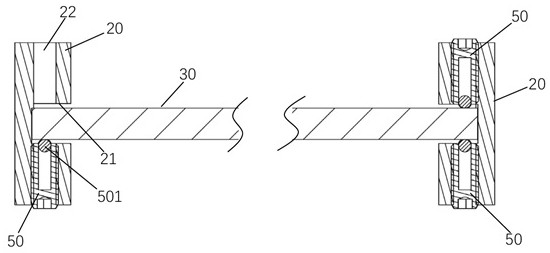

[0052] figure 1 It is a schematic diagram of a partial structure of a modular error testing device according to an embodiment of the present invention. figure 2 yes figure 1 Partial enlarged view of A in the center. image 3 is a schematic cross-sectional view of the modularized bit error testing device at the ball plunger 50 according to an embodiment of the present invention. Figure 4 It is a structural schematic diagram of an optical module 40 to be tested in a modularized bit error testing device according to an embodiment of the present invention. Figure 5 It is a structural schematic diagram of a test board 30 of a modular error testing device according to an embodiment of the present invention. Such as figure 1As shown, in one embodiment, the modularized bit error testing device includes a tester box 10, a channel rail 20, a test board 30 and a ball plunger 50 (see image 3 ). The tester case 10 is formed with a plurality of installation cavities 101 extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com