Rod end made of thermoplastic fiber-reinforced plastic

A technology of fiber-reinforced plastics and thermoplastics, which is applied in the direction of connecting rods and rods, rigid shaft couplings, etc., and can solve the problems of low strength and small loads of reinforced plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The terms "comprising and comprises" in this disclosure may mean "including and includes" or may have the meaning generally assigned to the term "comprising" in US patent law. If used in the claims, the terms "consists essentially of or consists essentially of" have the meaning ascribed to them under US Patent Law. Other aspects of the invention are described in or are apparent from the following disclosure (and are within the scope of the invention).

[0037] The present invention solves the problems of the prior art by providing a rod end which has a low weight compared to metal rod ends while also being able to transmit high mechanical loads (unlike existing plastic rod ends) and which can also be manufactured economically.

[0038] In certain embodiments, rod ends according to the present invention may be attachment elements for introducing tension and compression forces into various linkages, for example, for applications in the aerospace field.

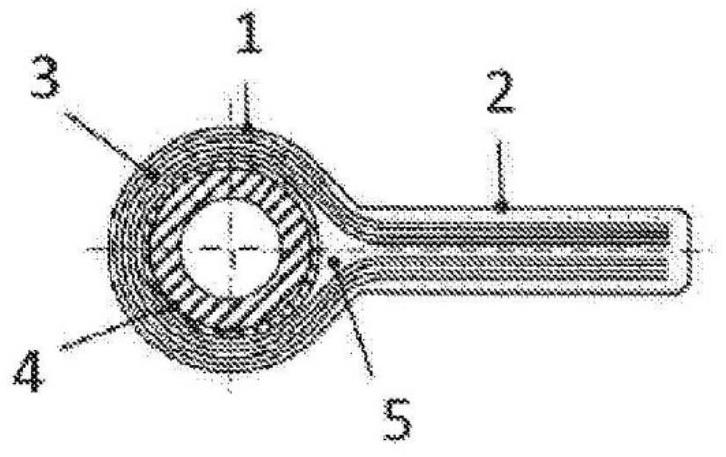

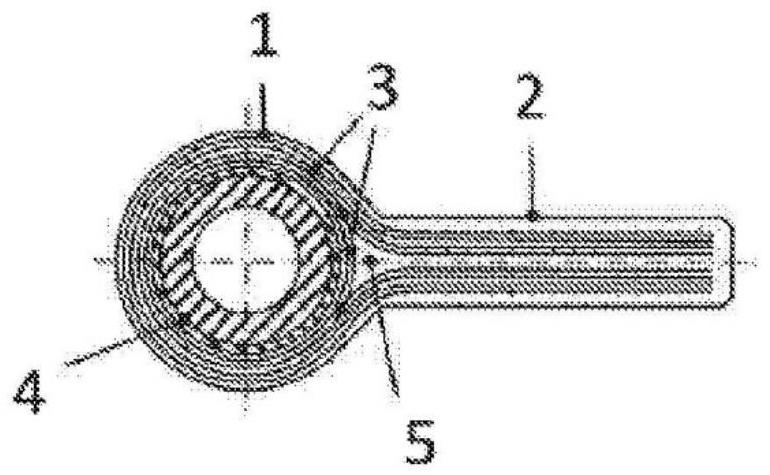

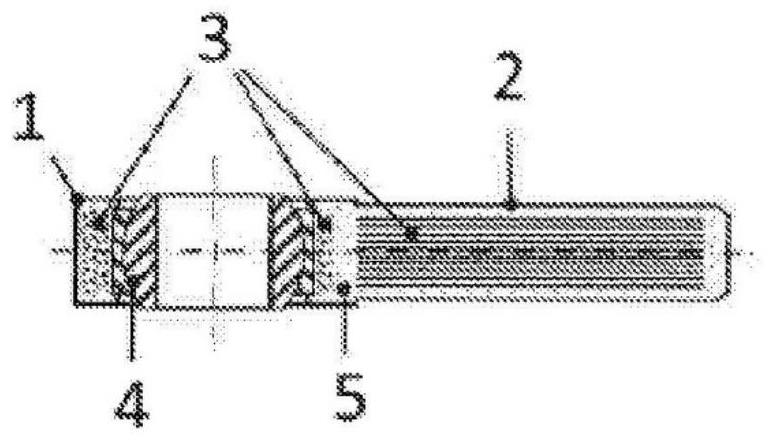

[0039] The rod en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com