Auxiliary film feeding device for medical ultrasonic probe

An ultrasonic probe and membrane device technology, applied in ultrasonic/sonic/infrasonic diagnosis, application, medical science, etc., can solve the problem of high labor intensity of manual membrane application, and achieve the effect of simplifying cumbersome procedures, improving replacement efficiency, and avoiding crossover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

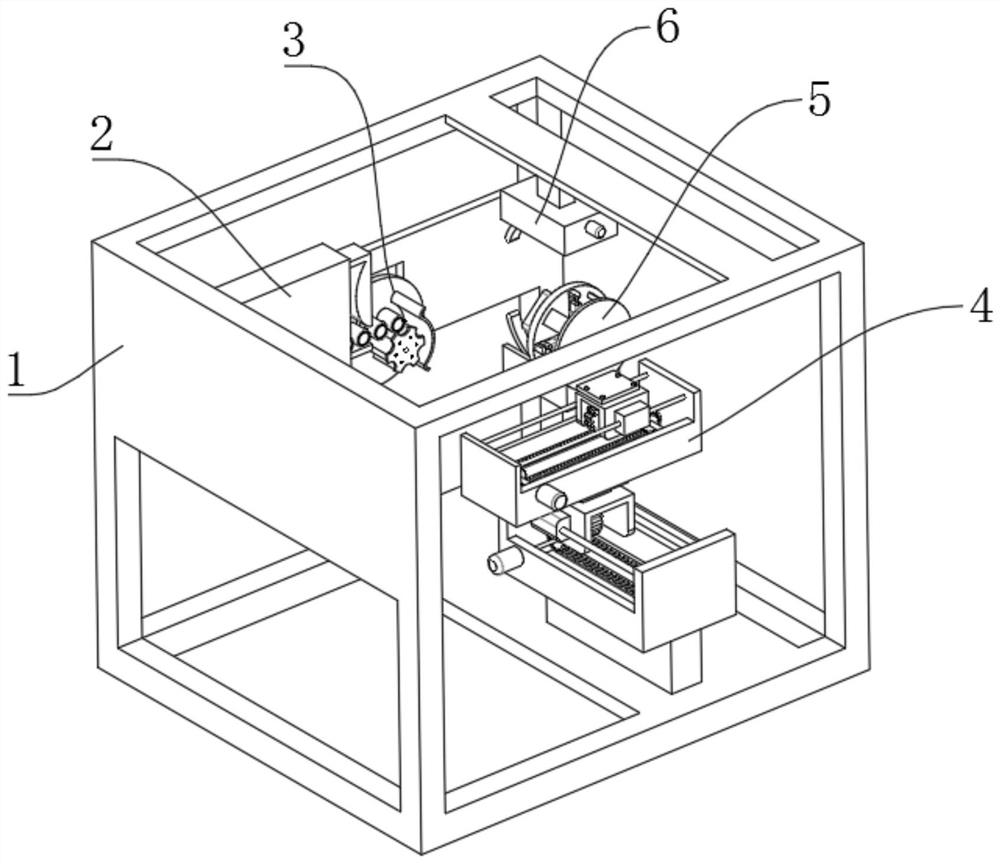

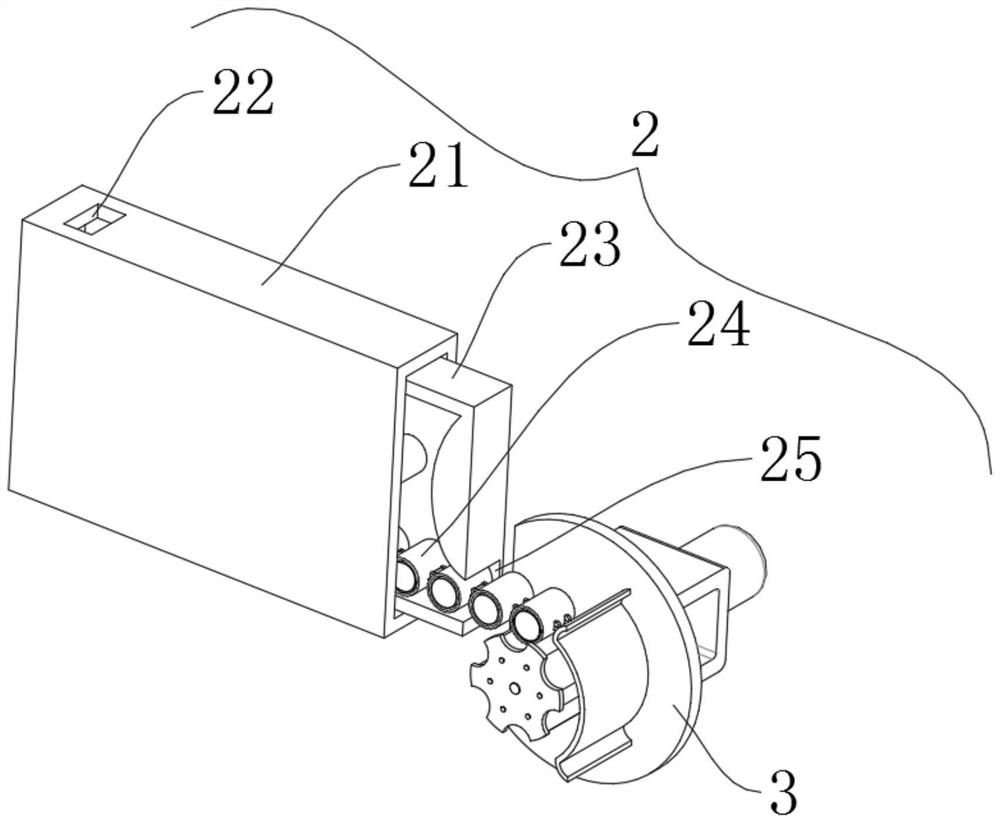

[0034] refer to Figure 1-5, an auxiliary film application device for medical ultrasonic probes, comprising a support frame 1, a film storage mechanism 2, a film feeding mechanism 3, a transmission mechanism 4 and a film support mechanism 5, the film storage mechanism 2 is installed on the inside of the support frame 1, and sent The membrane mechanism 3 is installed at the outlet end of the membrane storage mechanism 2, and the transmission mechanism 4 is installed inside the support frame 1 to drive the membrane support mechanism 5 to move laterally and longitudinally inside the support frame 1;

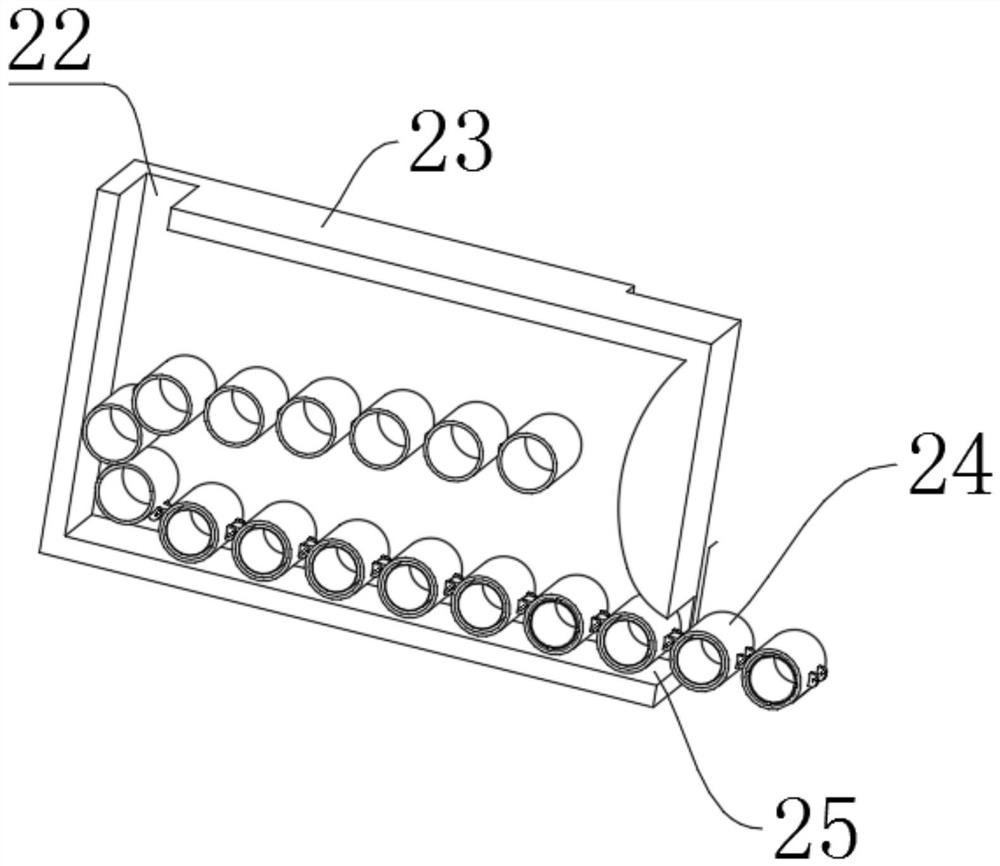

[0035] The film storage mechanism 2 includes a first mounting frame 21, a storage box 22 is slidably installed inside the first mounting frame 21, and a number of film storage assemblies 24 are placed inside the storage box 22, and chain belts can be formed between several film storage assemblies 24, adjacent to each other. The two storage membrane assemblies 24 are hinged to each o...

Embodiment 2

[0040] Medical ultrasound probes in the prior art are generally rectangular or square in structure, so the isolation membrane needs to be formed into a rectangle or square shape after stretching, so that it is more convenient to set the isolation membrane on the corresponding ultrasonic probe. The main application of this implementation is to design the membrane support mechanism On a square ultrasonic probe; in addition, after the membrane supporting mechanism stretches the isolation membrane, it needs to separate the isolation membrane from the membrane storage chamber 241, so that the isolation membrane can be set on the ultrasonic probe, so this embodiment also designs a The transmission mechanism 4 used to control the movement of the membrane support mechanism 5;

[0041] refer to Figure 1-9 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the transmission mechanism 4 includes a first transmission assembly 41 and a seco...

Embodiment 3

[0051] In Example 2, after the ultrasonic probe is set with the isolation membrane through the film supporting mechanism 5, it is difficult for the isolation membrane to fit the ultrasonic probe completely, which requires the isolation membrane to be flattened. If it is manually flattened, it will cause The isolation membrane is polluted, so this embodiment designs a covering mechanism for flattening the isolation membrane;

[0052] refer to Figure 1-10 , as another preferred embodiment of the present invention, the difference from Embodiment 2 is that two mutually symmetrical coating mechanisms 6 are installed inside the support frame 1, and the membrane supporting mechanism 5 is located between the two coating mechanisms 6; The film mechanism 6 includes a sixth mounting frame 61, a fifth motor 62, a worm screw 63, a worm wheel 64, and two mutually parallel lamination claws 65. The worm wheel 64 is fixedly connected coaxially with the coating claw 65 through the same rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com