Pneumatic fixture for grinding machine processing

A pneumatic and grinding machine technology, applied in the direction of grinding the workpiece support, etc., can solve the problems of affecting the qualified rate of the workpiece, limiting the degree of freedom of rotation, time-consuming and inconvenient, etc., to simplify the cumbersome process of clamping, ensure the overall strength, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

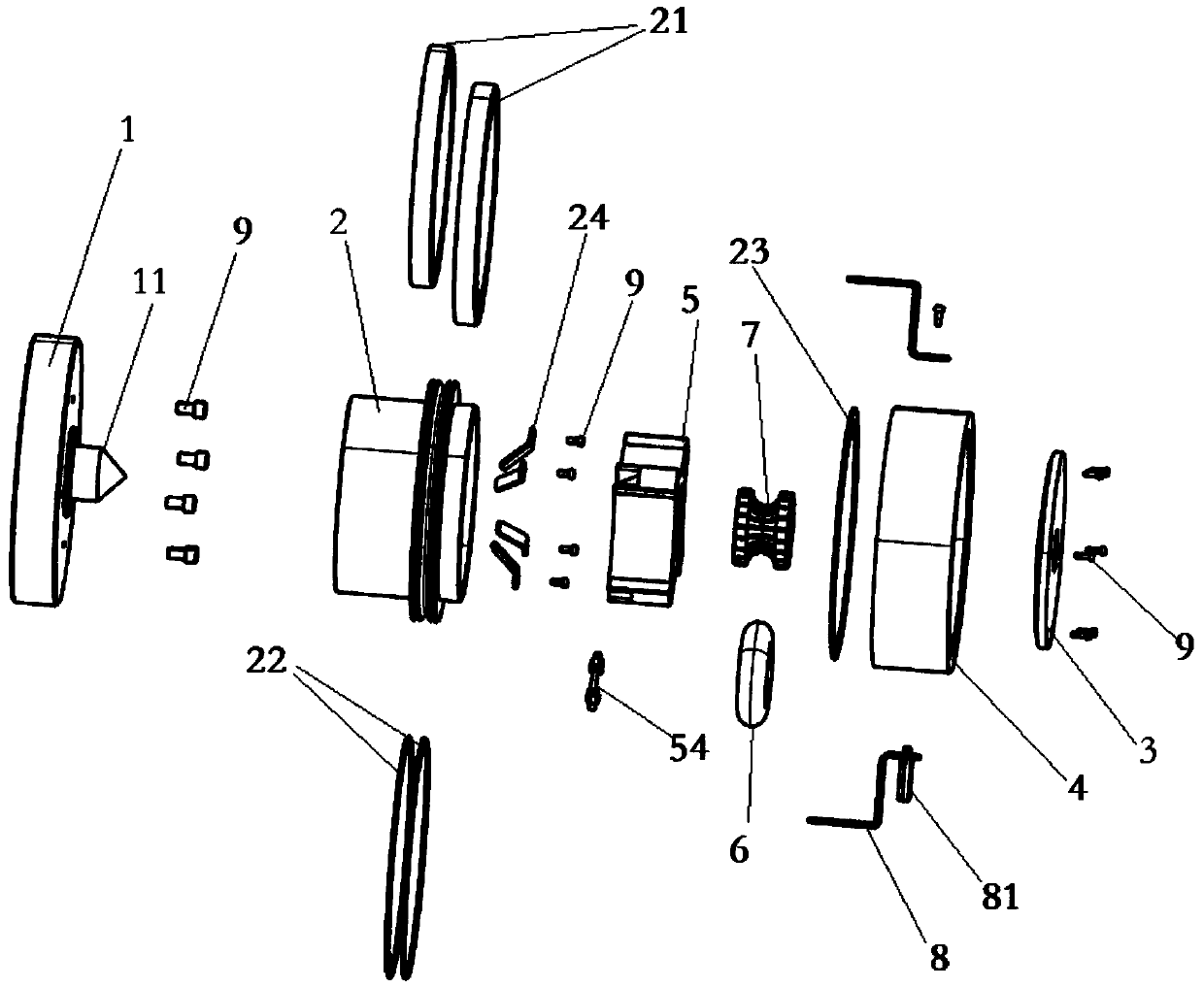

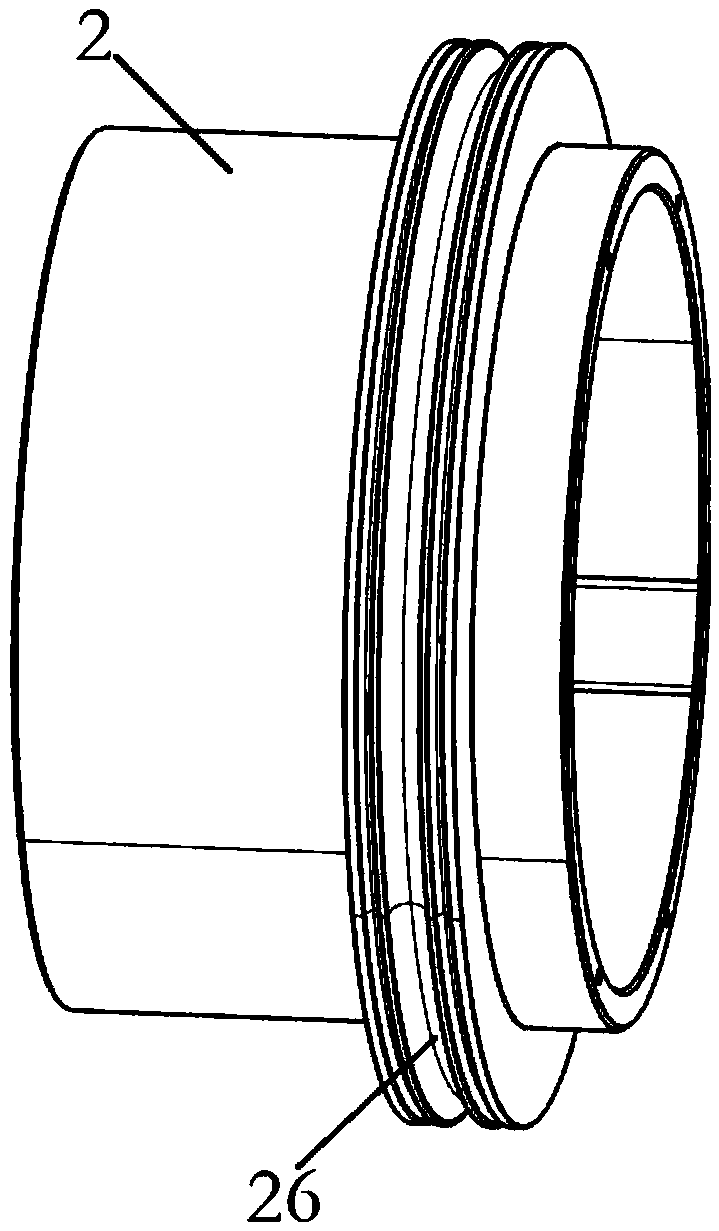

[0040] combine figure 1 As shown, a pneumatic clamp for grinding machine processing includes a rotating shaft plate 1 , a rotating core and a fixed ring 4 , and the rotating core includes a core shell 2 and an end cover 3 . The center of the rotating shaft disk 1 is provided with a front tip 11 for positioning the workpiece. Both the end faces of the movement shell 2 and the end cover 3 are provided with circular through holes for the passage of workpieces such as shafts and rods. The rotating shaft of described rotating shaft disc 1 and processing grinder, the end face of movement shell 2 and rotating shaft disc 1, end cover 3 and movement housing 2 are all connected by screw 9, when the rotating shaft of grinding machine rotates, rotating shaft disc 1 and Turn the movement to follow the rotation.

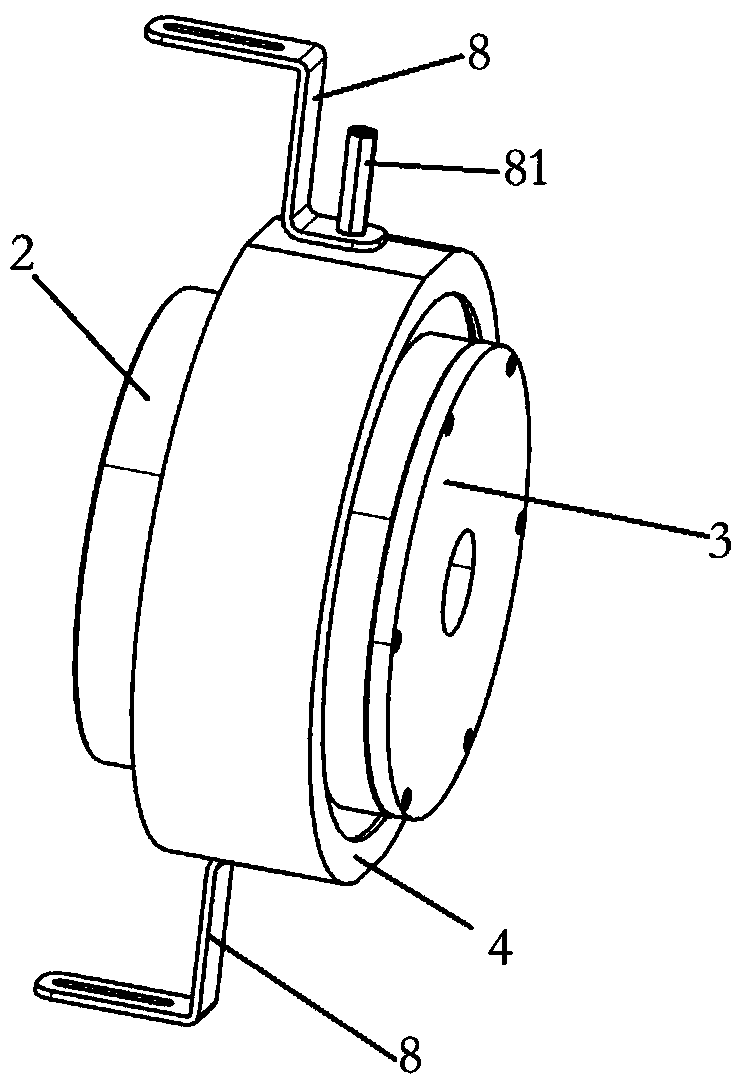

[0041] combine figure 2 As shown, the fixed ring 4 is fixedly connected with the main body of the grinder through the fixed bracket 8, and the fixed ring 4 is fixed in positio...

Embodiment 2

[0046] On the basis of the above-mentioned embodiments, this embodiment combines Figure 5 As shown, a spring leaf 24 is installed on the quarter point of the movement cavity 25 . combine Image 6 As shown, the surface of the airbag frame 5 is provided with a spring plate installation groove 52 corresponding to the spring plate 24 . The air bag frame 5 is installed in the movement cavity 25, and the leaf spring 24 enters the spring leaf mounting groove 52. There is a gap between the four corners of the air bag frame 5 and the inner wall of the movement cavity 25, and the air bag frame 5 can compress the spring leaf to carry out small displacement and turn.

[0047]The through holes of each part of the fixture are concentric with the front top 11, and the workpiece is automatically centered during installation, and when the four sides of the airbag frame 6 are under uneven force, the spring leaf 24 will be compressed to achieve a small position and rotation, and automatic dev...

Embodiment 3

[0049] On the basis of the above-mentioned embodiments, this embodiment combines Image 6 with Figure 7 As shown, the airbag frame 5 is cross-shaped, and a through hole is arranged in the middle thereof. The airbag frame 5 is provided with an elastic ring installation cavity 51 for positioning the elastic ring 7 . In addition, an airbag groove 53 is provided in the middle of the side wall of the elastic ring installation cavity 51 for positioning the airbag 6 . The ends of the four protruding sides of the airbag frame 5 are provided with spring mounting grooves 52 . The cross-shaped structure improves the force sensitivity of the airbag frame 5 and improves the centering accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com